Steel plate hydraulic-forming production method and process of construction fastener

A production method, hydraulic forming technology, applied in the field of building construction equipment manufacturing, can solve the problems of high energy consumption, low safety, difficult material components to meet standards, etc., and achieve the effect of low price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and examples of the right-angle fasteners in the embodiments (the manufacturing process of the rotary and docking fasteners is the same as that of the right-angle fasteners, and will not be repeated):

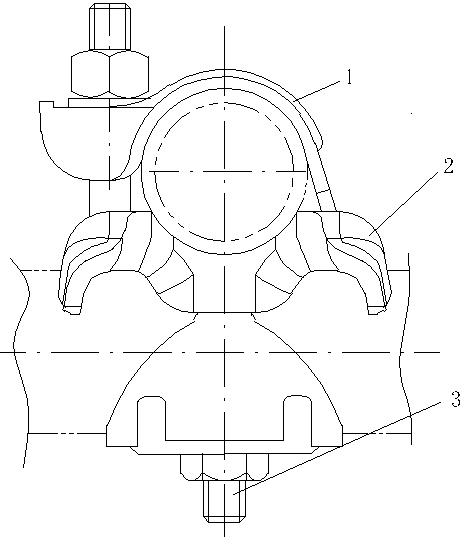

[0021] see Picture 1-1 It is the product picture of the right-angle fastener. The fastener is composed of two fastener cover plates 1 (referred to as the cover), a fastener seat plate 2 (referred to as the fastener seat) and two sets of bolts 3.

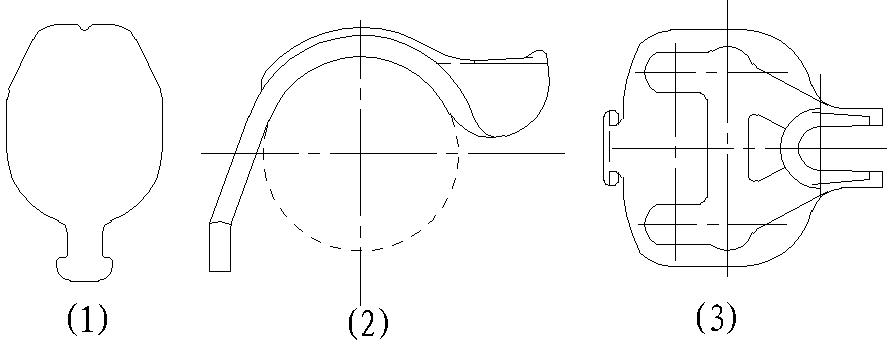

[0022] Figure 1-2 The exploded diagram of the manufacturing process for the fastener cover: ⑴ is the material block made of the steel plate by shearing; ⑵ is the process part after the material block is placed in the hydraulic press and formed by hydraulic hard molding; 3 is the part punched After the hole becomes the finished part.

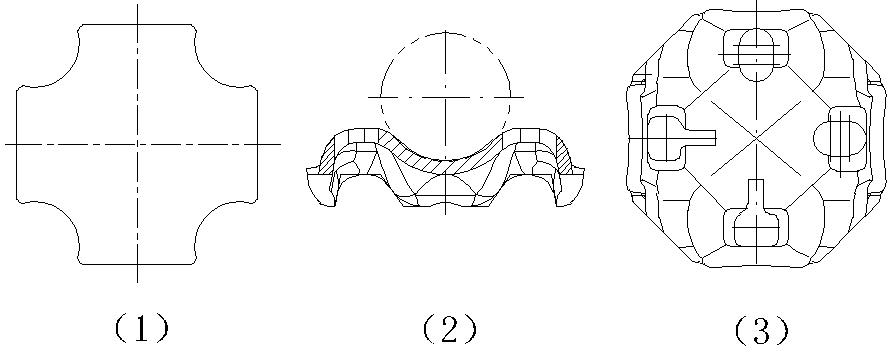

[0023] Figure 1-3 The process diagram for the production process of the fastener seat plate: ⑴ is the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com