Circular tube cross-shaped welding auxiliary clamping method

A cross welding and clamping technology, applied in welding equipment, laser welding equipment, tubular objects, etc., can solve problems such as overall deformation of the cross shape, reduce energy consumption, ensure production speed, and be less susceptible to thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

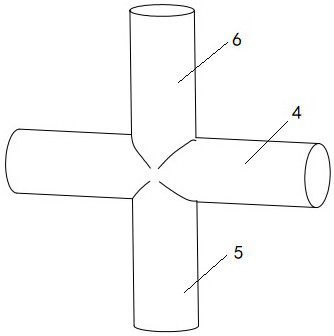

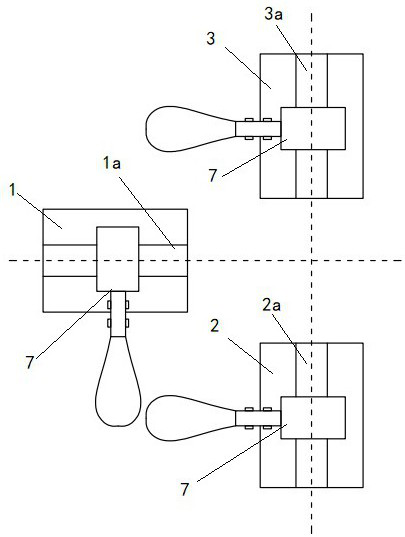

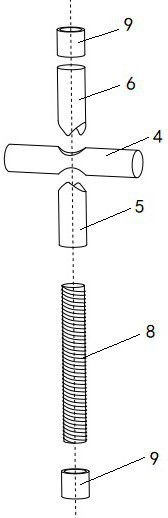

[0016] Embodiment 1. Please combine the auxiliary clamping method for cross welding of round tubes involved in this embodiment. image 3 As shown, the use of auxiliary tools including a screw 8 and a cylindrical nut 9, the screw 8 is used as a guide rod, on the screw 8, the first short tube 5 is axially threaded, the long tube 4 is traversed from the welding position, and the second is axially threaded. The short tube 6 makes the first short tube 5, the long tube 4 and the second short tube 6 form a cross-shaped structure. The cylindrical nut 9 is used as the top column, and the cylindrical nut 9 is screwed on the two ends of the screw 8 completed by the above-mentioned sleeve and tightened so that the first short tube 5 and the second short tube 6 are axially compressed to complete the assembly. Put the assembled cross-shaped structure into each positioning block for clamping as in the prior art, the upper and lower sides of the second slotted positioning block 2 and the thir...

Embodiment 2

[0017] Embodiment 2. Please combine the auxiliary clamping method for cross welding of round tubes involved in this embodiment. Figure 4 As shown, the use of auxiliary tools includes a guide rod 10 and a cylindrical nut 11 with a rod, the rod body of the guide rod 10 is a smooth round rod, the head of the guide rod 10 is provided with threads, and the tail end of the guide rod 10 is a section with a diameter larger than that of the guide rod 10. The cylindrical section of the rod body but not larger than the diameter of the first short tube 5 and the second short tube 6, on the guide rod 10, the first short tube 5 is axially sleeved in sequence, the long tube 4 is crossed by the welding position, and the axial penetration is Cover the second short tube 6 so that the first short tube 5 , the long tube 4 and the second short tube 6 form a cross-shaped structure. The cylindrical nut 11 with rod is used as the top column, and the cylindrical nut with rod 11 is screwed on the head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com