Maintenance technology of carbon fiber tube for combination mold core

A technology of combining molds and carbon fiber tubes, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult internal cleaning, high energy consumption of consumables, and achieve the effect of saving materials, saving energy and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

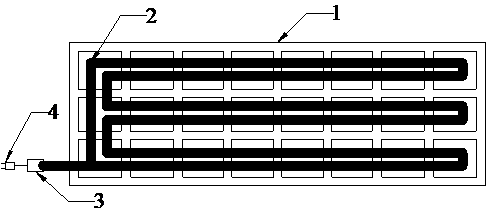

[0007] The present invention will be further described below in conjunction with the accompanying drawings. As shown in the figure, in the combined mold frame 1, carbon fiber tubes 2 are installed, and the carbon fiber tubes 2 are arranged in a serpentine shape in the combined mold frame 1, and finally both ends are connected to the controller 3, and the controller 3 is connected to the frame 1 outside the plug 4 connected. When the prefabricated wallboard needs to be maintained, the plug 4 is connected to the power supply, the controller 3 is set, and the maintenance can be performed after adjusting to the maintenance temperature; or the maintenance temperature and time can be set in stages to carry out the maintenance in stages.

[0008] The present invention is provided with a carbon fiber tube maintenance system in the mold, which can effectively solve the problem of steam curing and curing for simultaneous production of multiple prefabricated wall panels.

[0009] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com