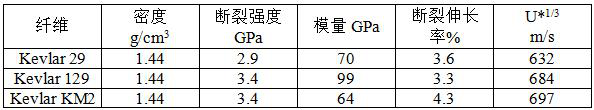

High-strength and high-toughness para-aramid fibers and preparation method thereof

A technology of para-aramid fiber and manufacturing method, applied in dry spinning method, wet spinning method, rayon cleaning/drying and other directions, can solve the problem that aramid fiber cannot achieve high strength and high elongation at break at the same time , to maintain production stability, high degree of orientation, and improve fiber elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

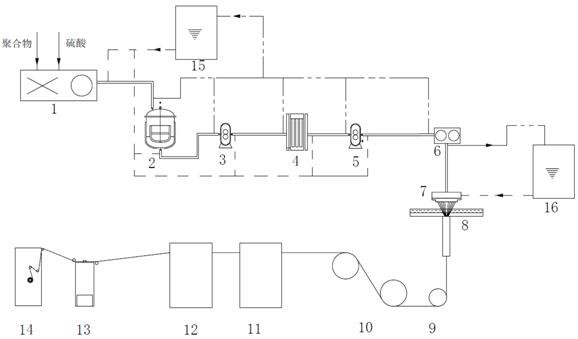

Method used

Image

Examples

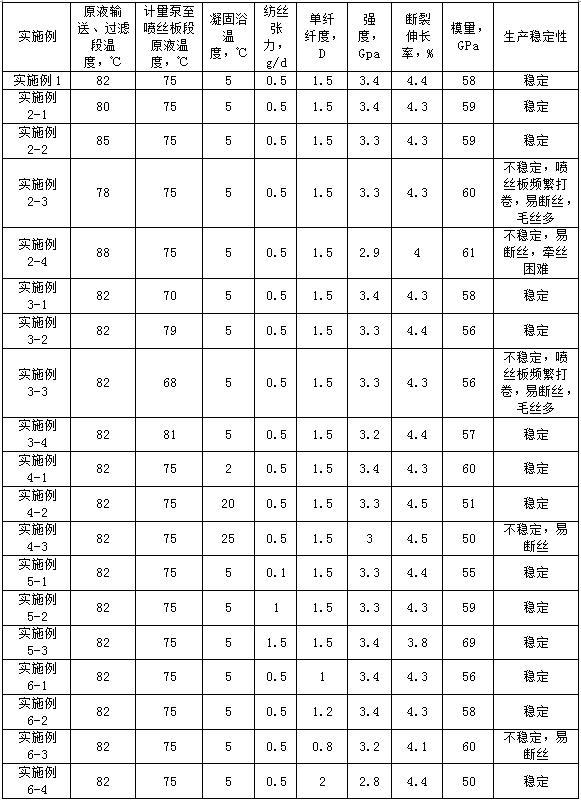

Embodiment 1

[0030] Dissolve the para-aramid polymer resin with an inherent viscosity of 6.3dl / g in 100% concentrated sulfuric acid to make a spinning slurry with a solid content of 19.3%, which is then defoamed, filtered, and sent to the spinning The silk metering pump is used to transport the filaments to the spinneret through metering, and the filaments are spun into the air layer, and then enter the coagulation bath to form primary fibers. The primary fibers are washed, dried, oiled, and wound in sequence to make finished products. Among them, the temperature of the slurry in the defoaming, filtering, and conveying sections is 82°C, the temperature of the slurry in the section from the spinning metering pump to the spinneret is 75°C, the temperature of the coagulation bath is 5°C, and the washing and drying tension is 0.5g / d. The fineness is 1.5D.

Embodiment 2

[0032] This series of examples verifies the influence of the temperature conditions of the slurry in the defoaming, filtering, and conveying sections.

Embodiment 2-1

[0034] The difference between this embodiment and embodiment 1 is that the temperature of the slurry in the defoaming, filtering and conveying sections is 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com