Device and method for recycling waste ammonia gas in arsenic coking process

An ammonia gas and process technology, which is applied in the fields of ammoniated desulfurization and coking, can solve the problems of increasing the load of the gas blower, reducing the calorific value of coke oven gas, and expensive replacement of the catalyst of the ammonia incinerator, so as to ensure production stability and save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

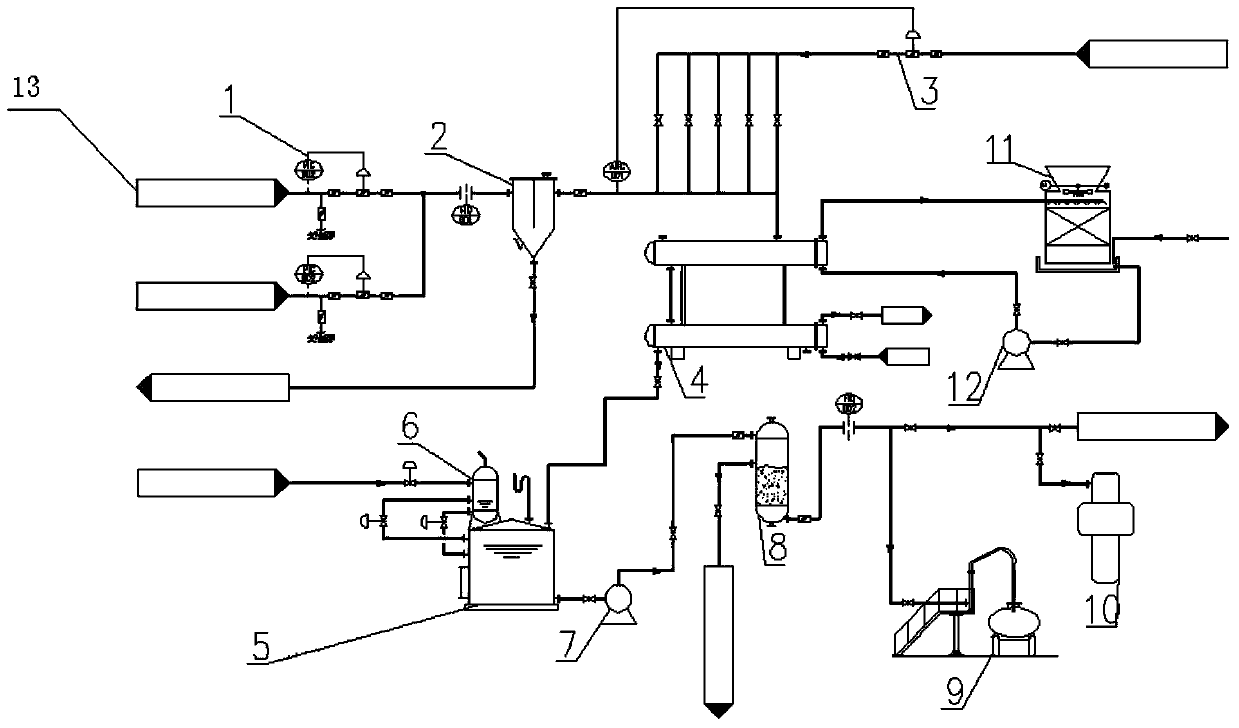

[0017] see figure 1 A device for recovering waste ammonia gas in the process of coking arsenic provided by an embodiment of the present invention includes a pressure stabilizer 1, a gas-liquid-solid separator 2, an ammonia water concentration regulator 3, a condensation cooler 4, a concentrated ammonia water storage tank 5, Diffuse ammonia gas collector 6, low temperature water tank 14, concentrated ammonia water pump 7, oil filter 8, circulating water cooling tower 11, circulating water pump 12 and recovery mechanism. The pressure stabilizer 1 is arranged on the top of the fixed ammonia tower 13 to regulate the pressure of the drawn waste ammonia gas. The gas-liquid-solid separator 2 is connected with the pressure stabilizer 1, and is used to separate the liquid and solid dross contained in the waste ammonia gas. The ammonia water concentration regulator 3 is connected with the gas-liquid-solid separator 2, and is used for adjusting the concentration of the ammonia gas to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com