Process method for replacement and repair of iron clad of main blade made of composite material

A composite material and process method, which is applied in the field of replacing and repairing the iron cladding of the main blade of the composite material, can solve the problems such as the iron cladding does not conform to the theoretical state, the shape of the blade cannot be guaranteed, and the life of the blade is affected, so as to improve the repair efficiency and improve the efficiency of the repair. The success rate of repairs, the effect of reducing the scrap rate of blades, and improving the quality of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

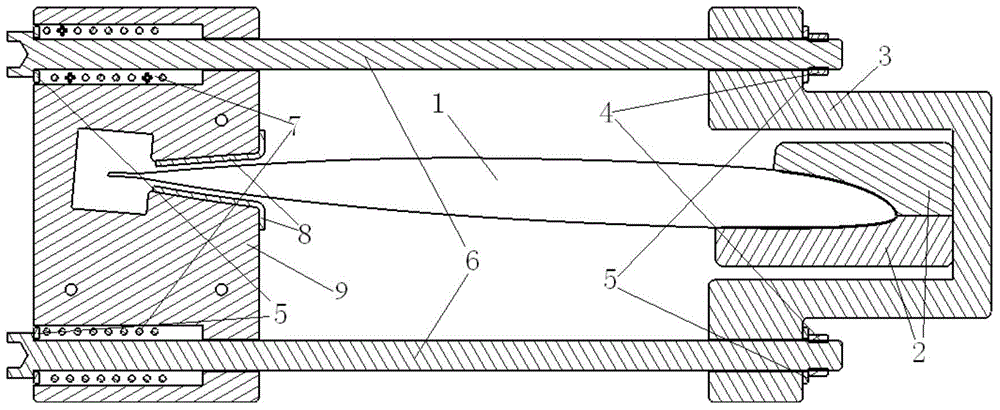

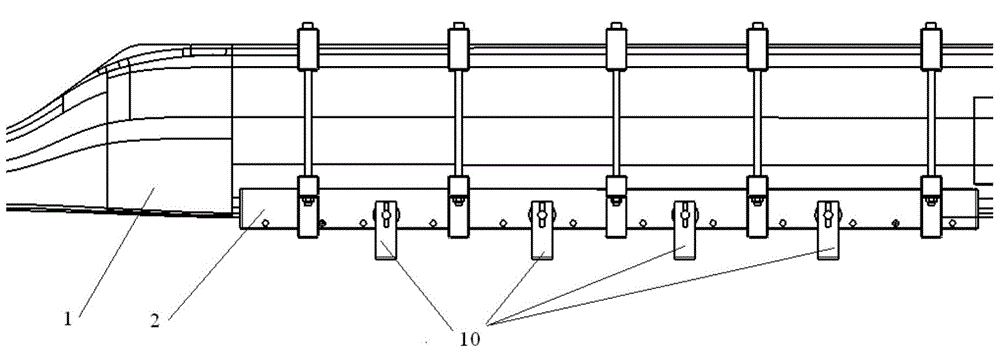

[0022] The invention mainly includes three aspects, namely, the design of iron-clad repair tooling, the design of pressurized auxiliary tooling, and the process of blade replacement and iron-clad repair.

[0023] Iron-clad repair tool

[0024] Iron-clad repair tool 2 adopts a segmented design, which is the same as the segment and length of blade 1. The repair tool is divided into upper and lower molds. After the molds are closed, it has a U-shaped die structure. The inner shape is the same as the outer shape of the blade 1 ( Iron-clad appearance) is the same, and each section of iron-clad needs 1 set.

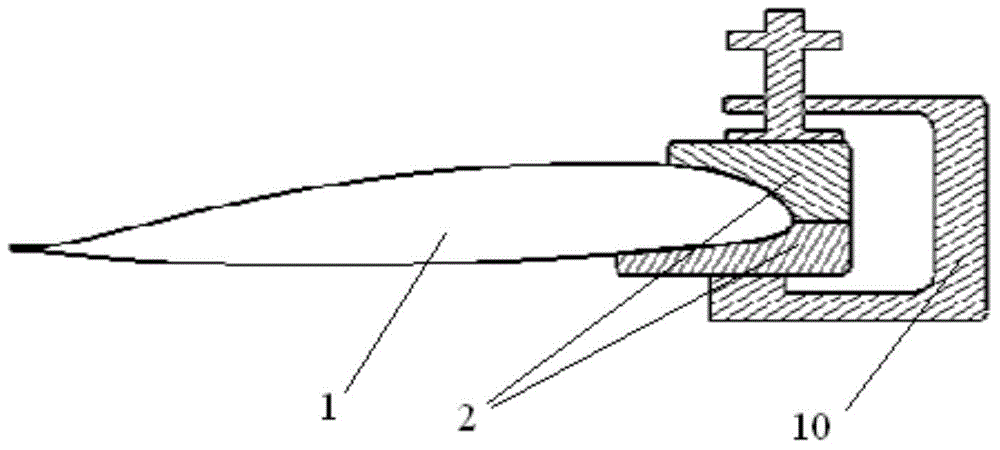

[0025] Pressurized auxiliary tooling

[0026] The pressurized auxiliary tooling is proposed to improve the bonding performance of the clad iron, and its structure includes the leading edge stopper 3, the trailing edge stopper 9, the pressurized nut 4, the spring 7, the gasket 5 and so on. The auxiliary pressurization tooling includes a front edge stopper 3, a pressurization n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com