Method for online recognition of deviation of strip steel in furnace

A strip deviation and strip technology, applied in the field of image recognition, can solve the problems of human eye fatigue, inability to provide deviation data, fault statistics and early warning functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The method for on-line identification of steel strip deviation in the furnace according to the present invention will be further explained in detail below in conjunction with specific embodiments and the accompanying drawings, but this explanation does not constitute an improper limitation of the present invention.

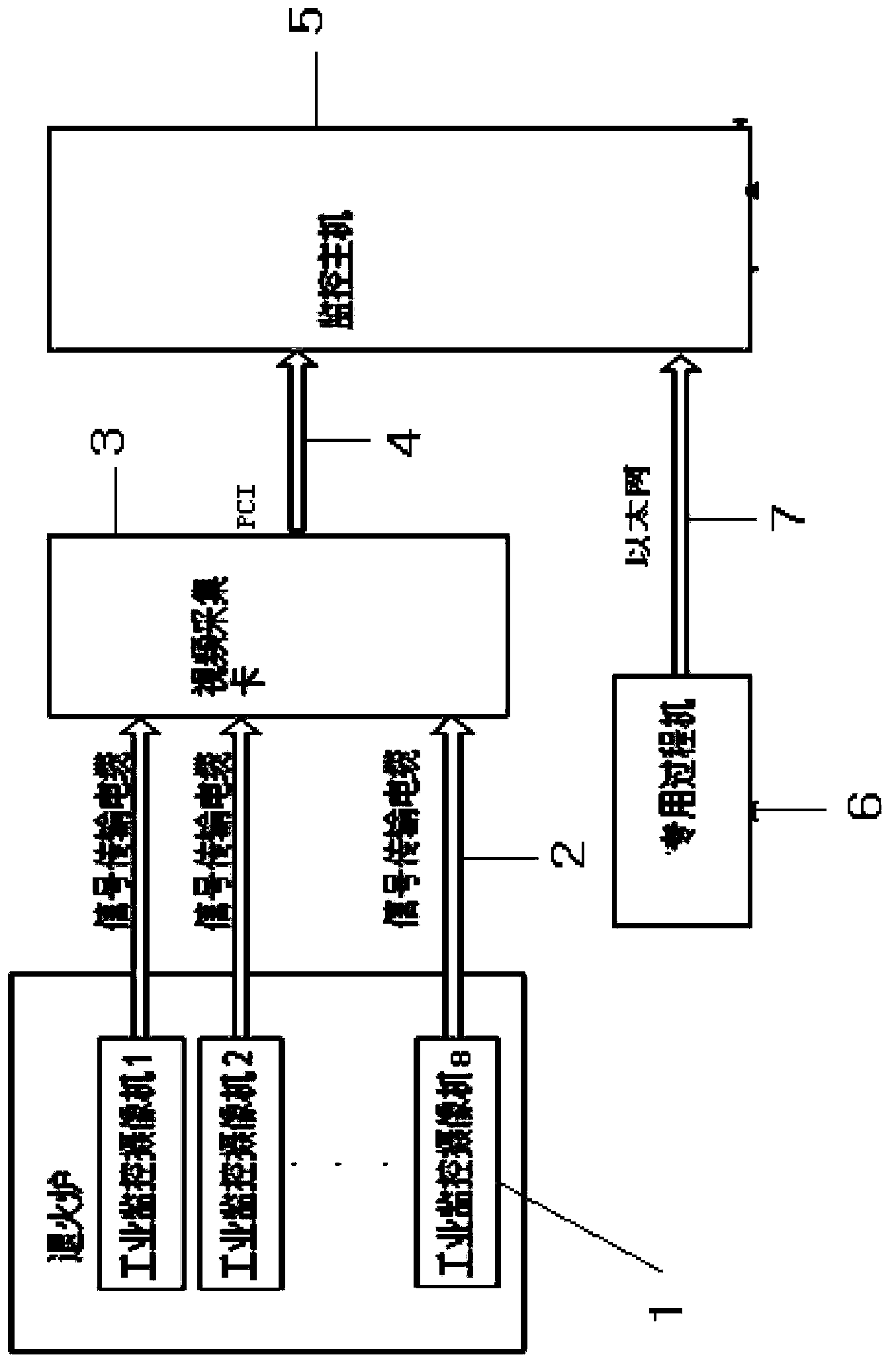

[0046] Such as figure 1 As shown, in this embodiment, the system for the method for online identification of steel strip deviation in the furnace includes: 1) 8 industrial monitoring cameras; 2) video acquisition card; 3) monitoring host; 4) dedicated process machine. Wherein, the industrial monitoring camera 1 is all connected with the video acquisition card 3 by the signal transmission cable 2, and the industrial monitoring camera 1 is evenly installed on the vertical direction of the steel strip production line in the annealing furnace, so that the image taken includes at least one strip steel The edge of the side and the edge of the shaft roller; the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com