Shunting system of sintering smoke circulating loop

A technology of circulation loop and shunt system, applied in the field of iron and steel metallurgy, can solve the problems of uneven flow field, bias flow in the width direction, and difference in the flow of combustion accelerant, and achieve the effects of ensuring production stability, slowing down hedging, and suppressing bias flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

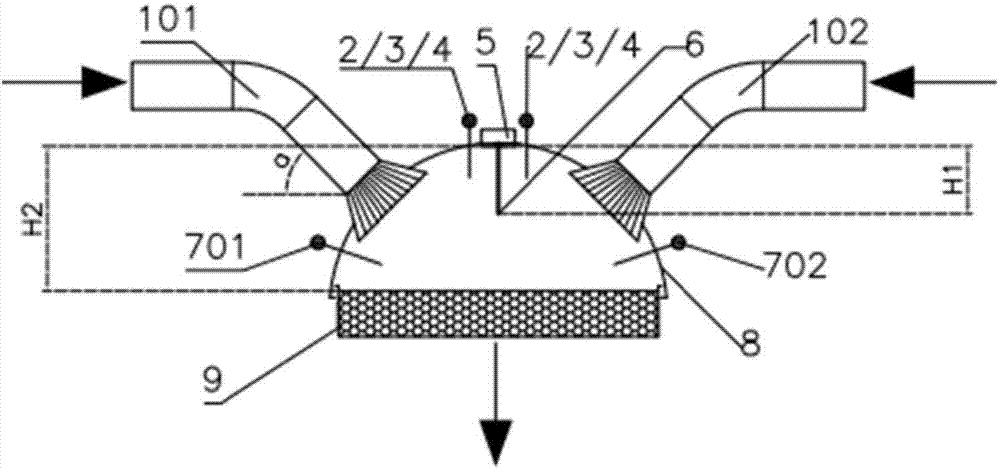

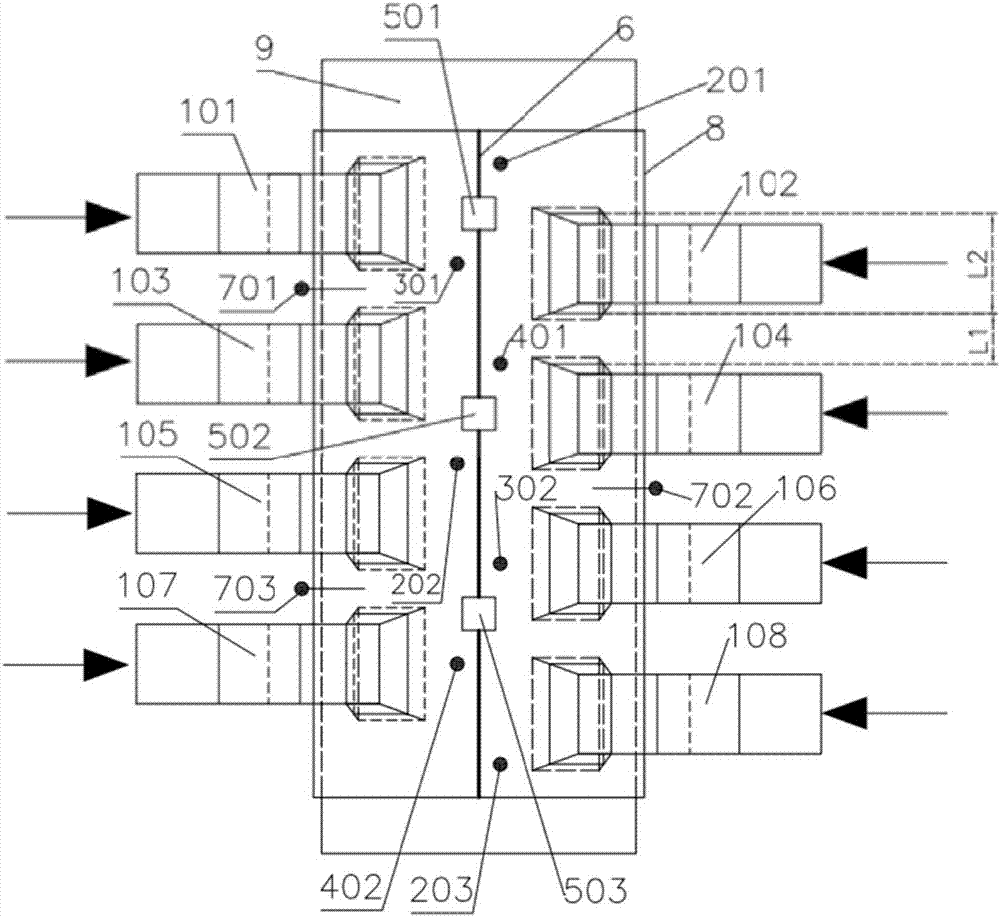

[0029] Such as figure 1 and figure 2 Shown is the distribution system of the sintering flue gas circulation loop of the present invention. After the circulating flue gas from the sintering machine is evenly distributed through the distribution pipes 101-108, it is introduced into the flue gas hood 8 of the sintering machine for cyclic sintering.

[0030] The sintering machine fume hood 8 covers the top of the sintering machine trolley 9, and the flue gas inlets are set at 45° on both sides of the width direction and communicate with the gas outlets of the shunt pipes 101-108; The plate 6 and the baffle plate 6 run through the entire sintering machine fume hood 8 with a height of H1, the distance between the top of the sintering machine fume hood 8 and the sintered material surface is H2, and H1 is 50% of H2.

[0031] The distribution pipes 101-108 on both sides of the fume hood 8 of the sintering machine are equal in number, all of which are 4, and the left and right sides a...

Embodiment 2

[0034] On the basis of the above-mentioned embodiment 1, this embodiment further defines:

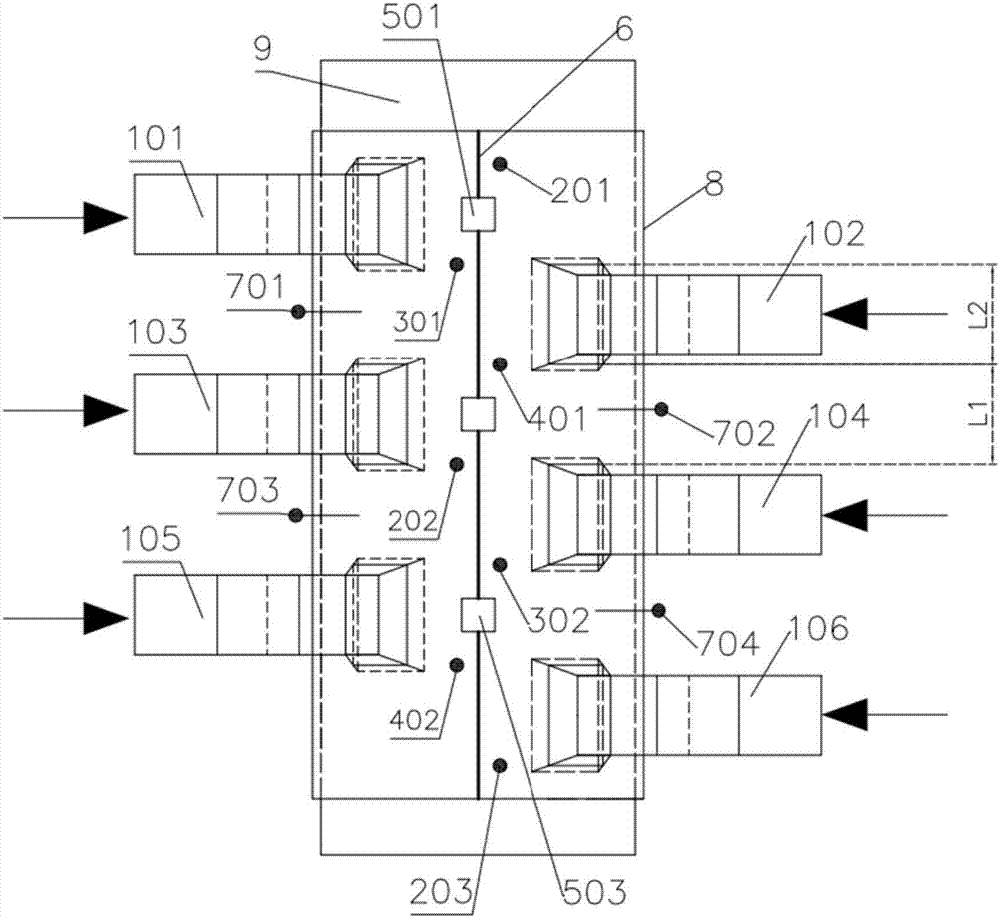

[0035] Such as image 3 As shown, except for the differences in the following structures, the structural layout of the distribution system of this embodiment is the same as that of Embodiment 1: the distribution pipes 101-106 on both sides of the sintering machine fume hood 8 are equal in number, all of which are three, and the left and right sides The side is arranged in a staggered arrangement; along the length direction of the sintering machine trolley 9, the distance between any two shunt pipes 101 / 103 is L1, the width of the shunt pipes 101-106 is L2, and L1 is equal to L2.

Embodiment 3

[0037] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment further defines:

[0038] Such as figure 2 or image 3 As shown, the structural arrangement of the shunt system in this embodiment is different from that in Embodiment 1 or Embodiment 2 in that:

[0039] (1) The angle between the flue gas inlet pipe of the sintering machine flue gas hood 8 and the horizontal direction can fluctuate within the range of 30° to 45°;

[0040] (2) The height of the baffle plate 6 is H1, which is not greater than the distance between the top of the sintering machine fume hood 8 and the sintering material surface is H2, and H1 can fluctuate within the range of 25% to 50% of H2;

[0041] (3) The distance between any two shunt pipes 101 / 103 is L1, the width of shunt pipes 101-108 is L2, and L1 can fluctuate within the range of 50%-100% of L2;

[0042] (4) The inclined pipes of the shunt pipes 101 to 108 connected to the flue gas hood 8 of the sintering machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com