Generator of wind power plant

A technology of generators and facilities, applied in the field of wind energy, which can solve the problems of gas flow obstruction, collapse, and strengthen the counterforce of airflow and plate, so as to achieve better coordination, avoid collapse and reduce counterforce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 to attach Figure 7 Shown:

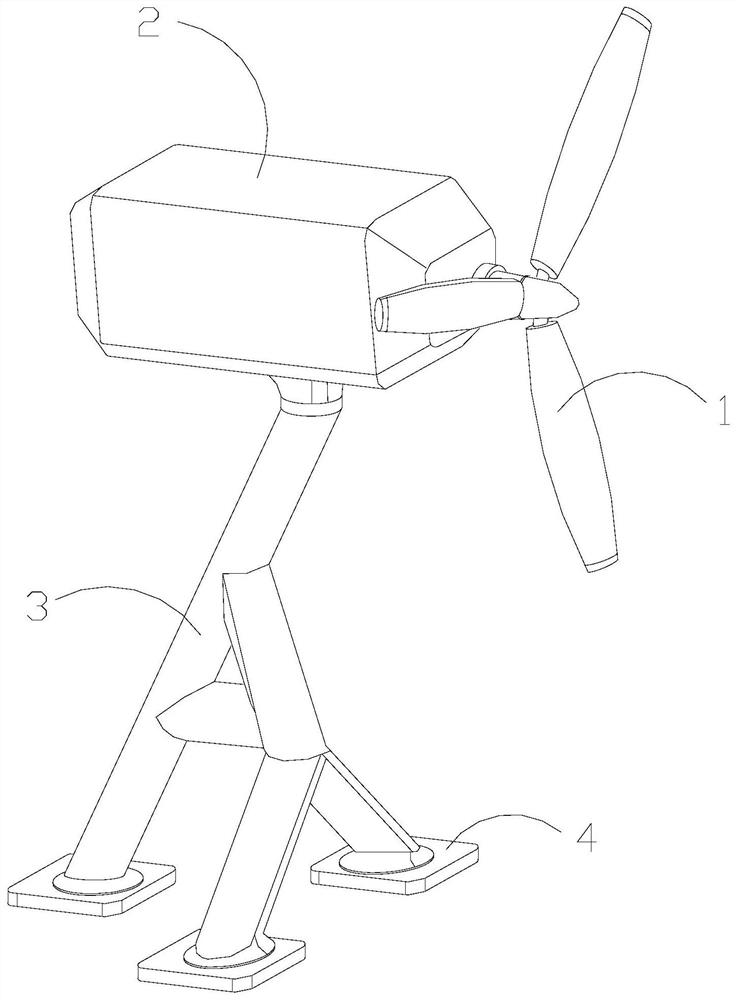

[0032] The present invention provides a generator for wind energy facilities. Its structure is provided with a turret 1, a motor 2, a tower 3, and a fixing seat 4. The turret 1 moves in front of the motor 2. 2 are movably connected at the bottom, and the fixed seat 4 is embedded and installed at the bottom of the tower 3 .

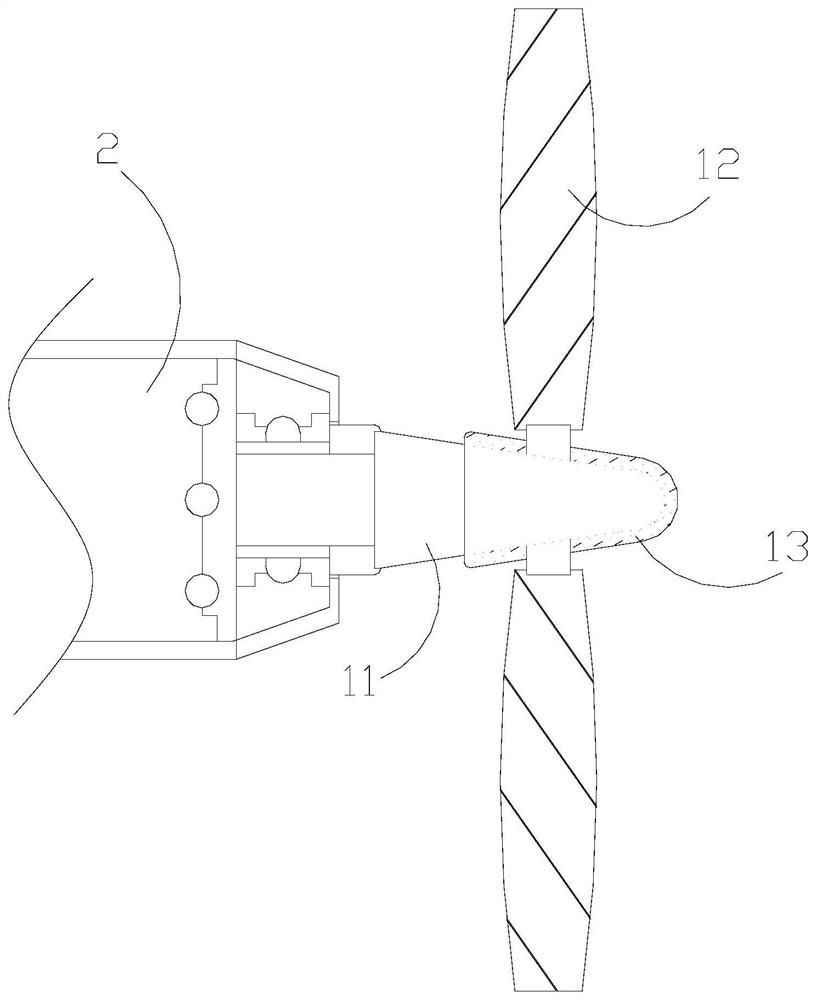

[0033] The turret 1 is provided with a pitch system 11, blades 12, and a rotor 13. The rotor 13 is socketed at the front end of the pitch system 11 and is movably matched. The lower end of the blades 12 is connected with the rotor 13 and is movable. Cooperate, the blades 12 cooperate with the pitch system 11 through the rotor 13 .

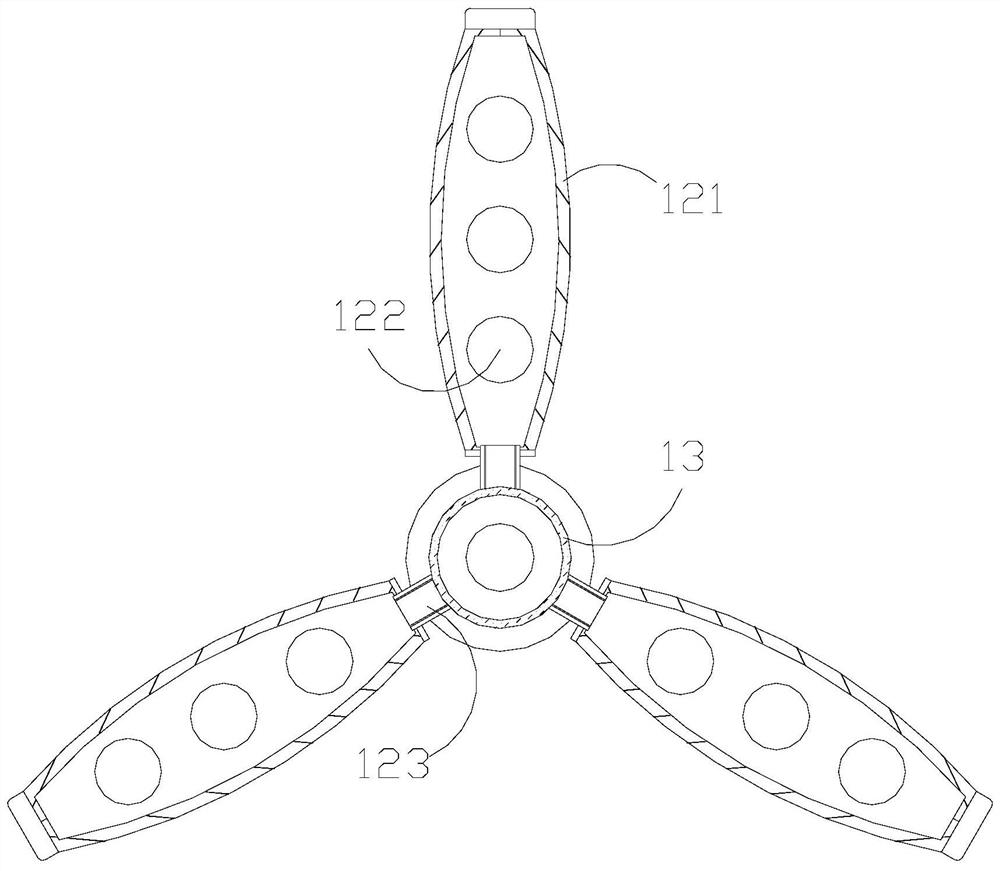

[0034] Wherein, the blade 12 is provided with a real paddle plate 121, a flow-through device 122, and an engaging rod 123, the flow-through device 122 and the real paddle plate 121 are an integrated structure and are located inside it through, and the connecting rod 12...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the variable body a23 is provided with a magnetic strip w1 and a corrugated plate w2, the magnetic strip w1 is fixedly connected to the outer end of the corrugated plate w2, the magnetic strip w1 is magnetic, and is in the form of a vertical strip plate, and the corrugated plate w2 is wrinkled, and can be folded and flattened. The change of the folded pressure of the folded plate w2 facilitates the change of the overall flattened area of the variable body a23. The magnetic field generated by the magnetic strip w1 makes the folded plate w2 cyclically perform folding. Compression and flattening changes.

[0043] Wherein, the wrinkled plate w2 is provided with a tearing block w21, a plate frame w22, and a reaction block w23, the tearing block w21 is fixedly connected to the upper end of the plate frame w22, and the reaction block w23 is embedded and connected inside the pleated plate w2, so The reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com