Coiling machine side guide plate with long service life

A technology of side guide plate and coiler, which is applied in the field of coiler, can solve the problems affecting product quality and production stability, long service life of slide plate, affecting production operation rate, etc., so as to reduce scratches and burrs and prolong service life life, ensuring product quality and the effects of production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail now in conjunction with accompanying drawing.

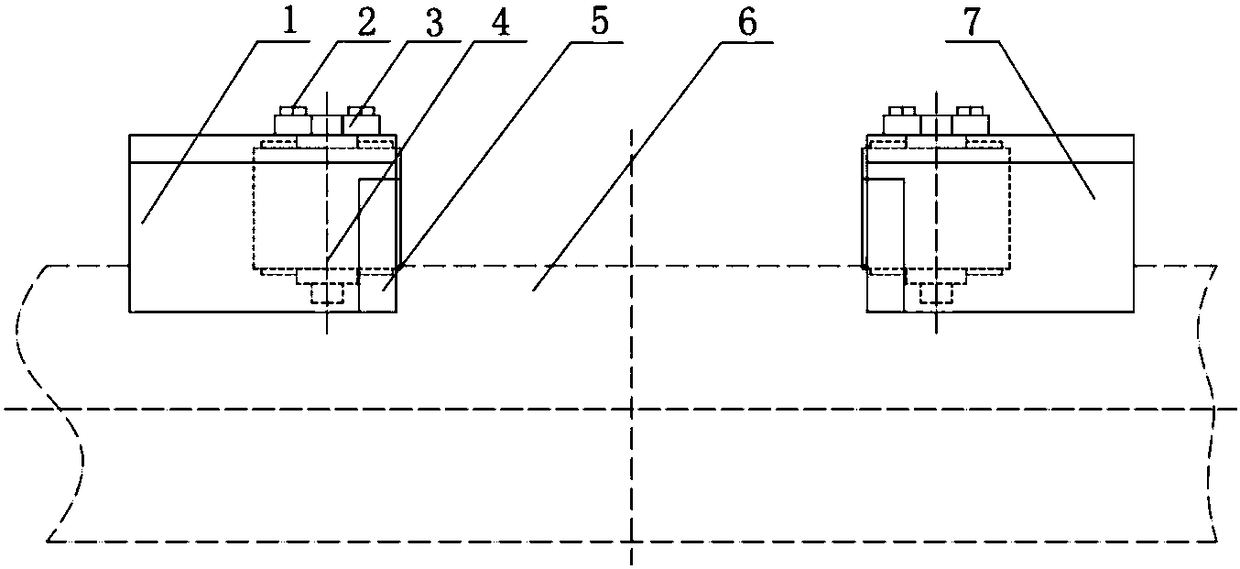

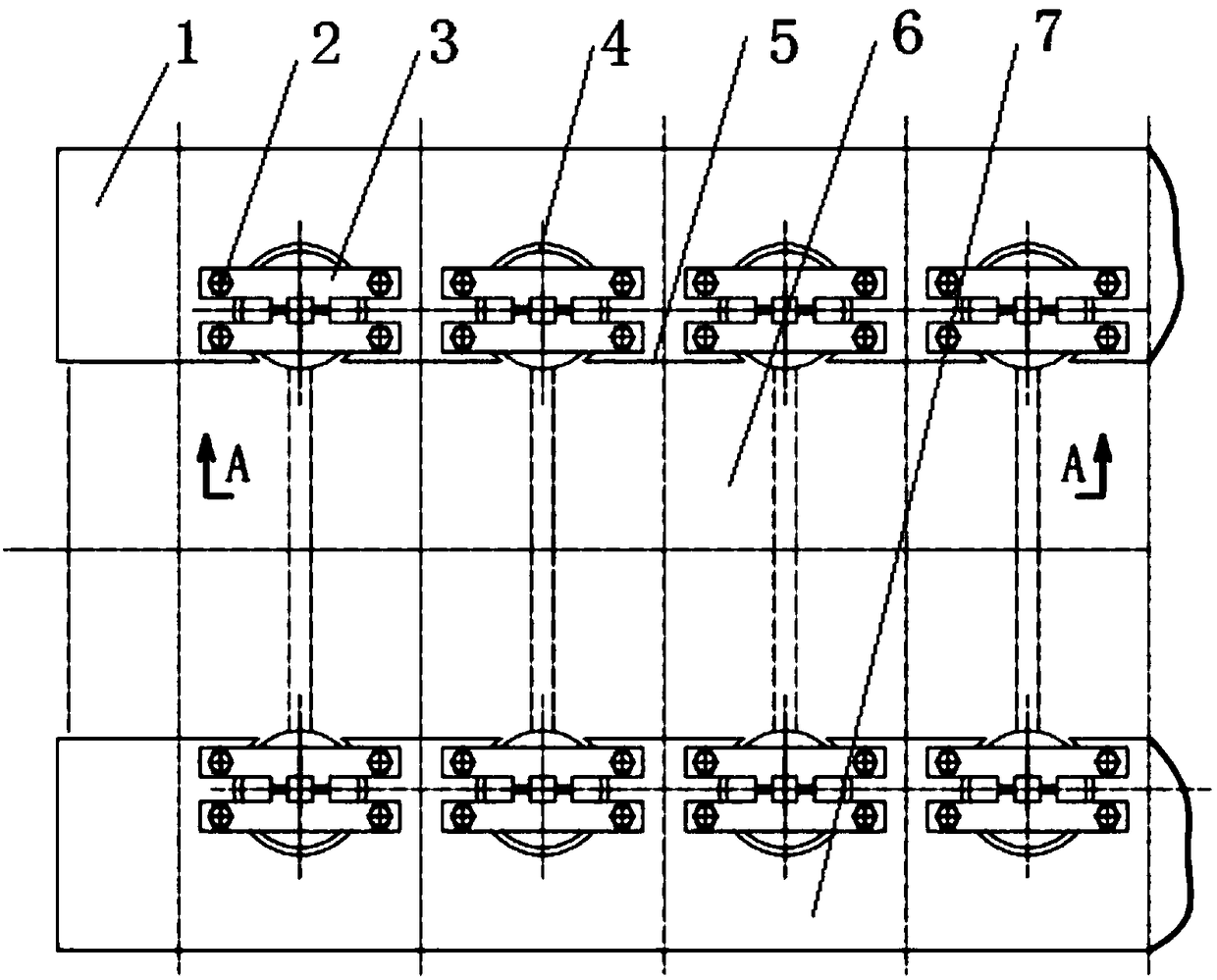

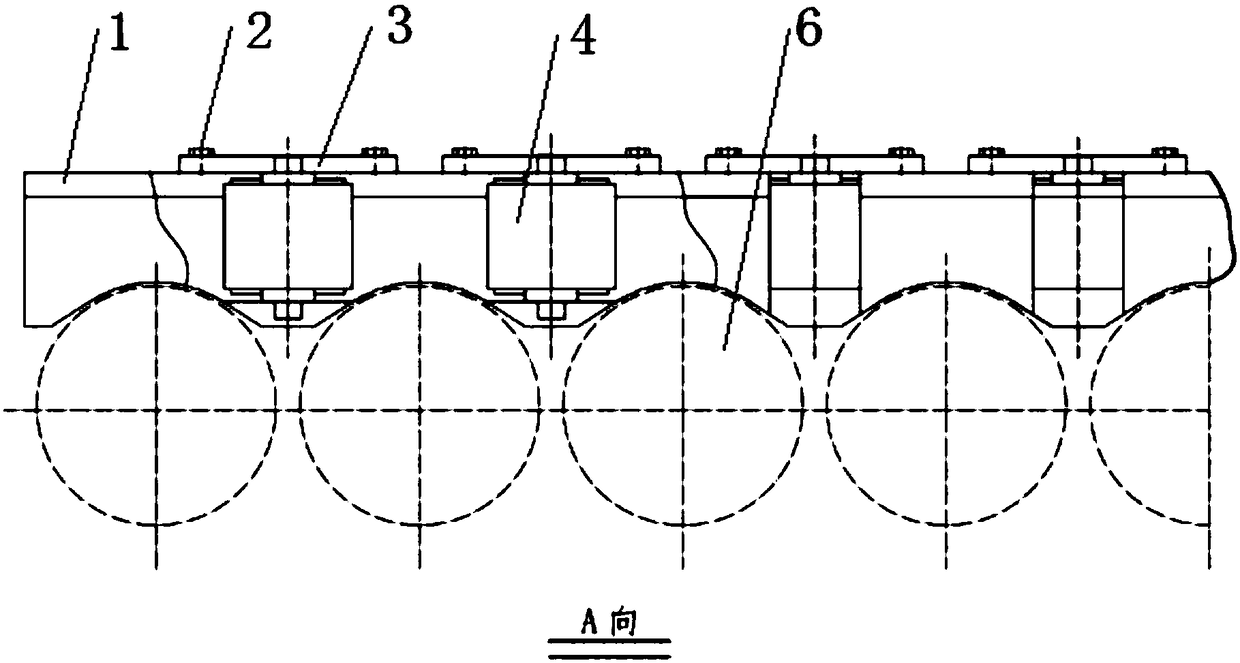

[0016] according to Figure 1 to Figure 3 The shown side guide plate of a long-life coiler includes a side guide plate body and a roller assembly. The side guide plate body is divided into a left guide plate body 1 and a right side guide plate body 7. The inside of the side guide plate body is provided with multiple A roller assembly 4, the roller assembly 4 includes a roller, a rolling bearing, a transparent cover, a seal, the roller surface is made of heat-resistant and wear-resistant hard alloy material, the rolling bearing is lubricated with dry oil, the roller surface is water-cooled, and has a long service life, and The roller assembly 4 can be used alternately up and down, so as to prolong the overall service life of the roller assembly 4 and reduce costs. On the side guide plate body, the lower end of the rolling bearing of the roller assembly is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com