Method for producing rose vinegar by pump reflux method

A technology of rose vinegar and pump backflow, applied in the field of food fermentation engineering, can solve the problems of long production cycle, high labor intensity, affected by temperature, etc., to overcome the bottleneck of seasonal restrictions, speed up the biological oxidation process, and ensure production stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

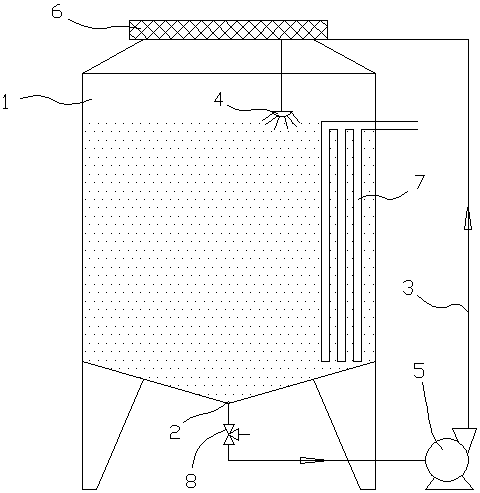

[0036] The invention relates to a method for producing rose vinegar by a pump reflux method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank 1 and building a nest, blooming, adding water, fermenting, and pressing , and the sterilization step, the tank 1 is cylindrical, the upper end of the tank 1 is open, and the lower end of the tank 1 is provided with a conical or arc-shaped bottom, preferably a conical bottom with a cone bottom angle of 150 degrees. The diameter-to-height ratio of the barrel is D:H=1:0.8, and the lowest point of the conical or arc-shaped bottom of the tank 1 is provided with a mash discharge port 2, and the mash discharge port 2 is connected to the upper port of the tank 1 through the pipe 3 The backflow nozzle 4 is connected, the pipeline 3 is provided with a liquid pump 5, and the upper port is provided with a grass cover 6, and the fermentation step includes:

[0037] (1) Medium frequency and...

Embodiment 2

[0045] The invention relates to a method for producing rose vinegar by a pump reflux method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank 1 and building a nest, blooming, adding water, fermenting, and pressing , and the sterilization step, the tank 1 is cylindrical, the upper end of the tank 1 is open, and the lower end of the tank 1 is provided with a conical or arc-shaped bottom, preferably a conical bottom with a cone bottom angle of 150 degrees. The diameter-to-height ratio of the barrel is D:H=1:0.9, and the lowest point of the conical or arc-shaped bottom of the tank 1 is provided with a mash discharge port 2, and the mash discharge port 2 is connected to the upper port of the tank 1 through the pipe 3 The backflow nozzle 4 is connected, the pipeline 3 is provided with a liquid pump 5, and the upper port is provided with a grass cover 6, and the fermentation step includes:

[0046] (1) Medium frequency and...

Embodiment 3

[0054] The invention relates to a method for producing rose vinegar by a pump reflux method, which comprises the steps of rinsing rice, steaming rice, cooling cooked rice, putting cooked rice into a tank 1 and building a nest, blooming, adding water, fermenting, and pressing , and the sterilization step, the tank 1 is cylindrical, the upper end of the tank 1 is open, and the lower end of the tank 1 is provided with a conical or arc-shaped bottom, preferably a conical bottom with a cone bottom angle of 150 degrees. The diameter-to-height ratio of the barrel portion D:H=1:1, the lowest point of the conical or arc-shaped bottom of the tank 1 is provided with a discharge port 2, and the discharge port 2 is connected to the upper port of the tank 1 through the pipe 3 The backflow nozzle 4 is connected, the pipeline 3 is provided with a liquid pump 5, and the upper port is provided with a grass cover 6, and the fermentation step includes:

[0055] (1) Medium frequency and large refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com