Prefabricated component embedded assembly and installation method thereof

A technology for prefabricated components and embedded parts, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult installation and construction of prefabricated components embedded parts, lack of standardization, etc., and achieve the effect of convenient disassembly and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

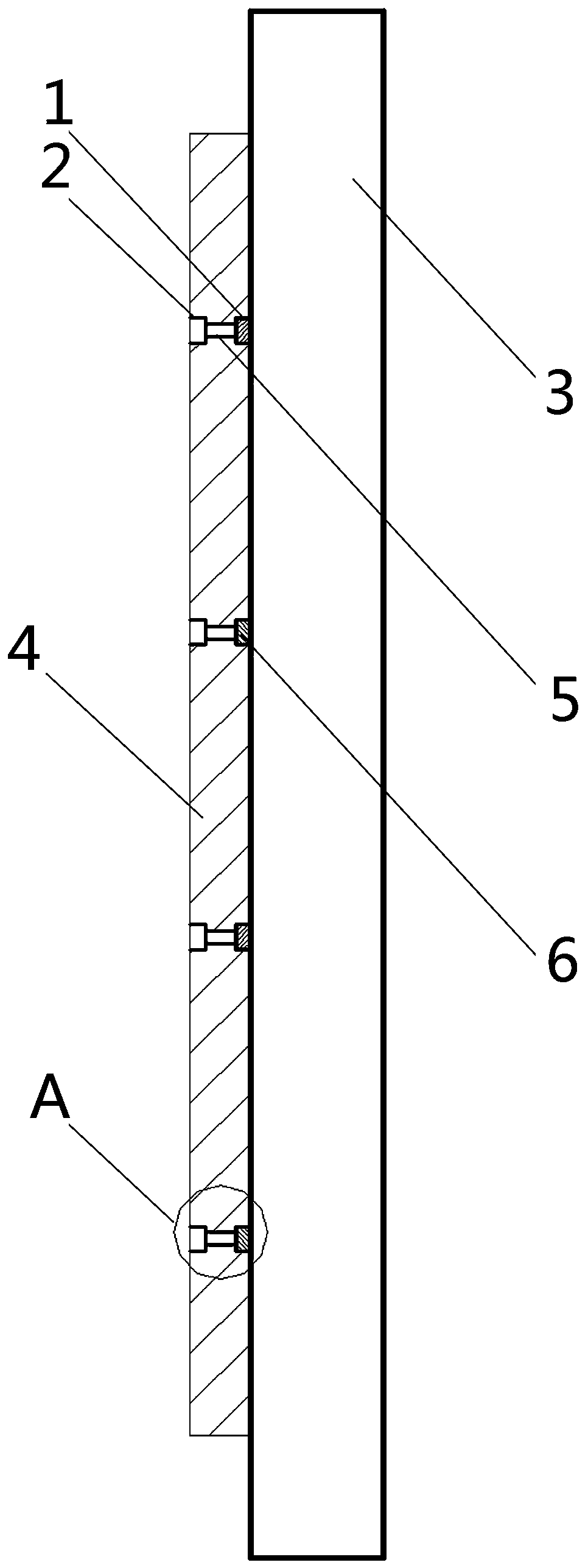

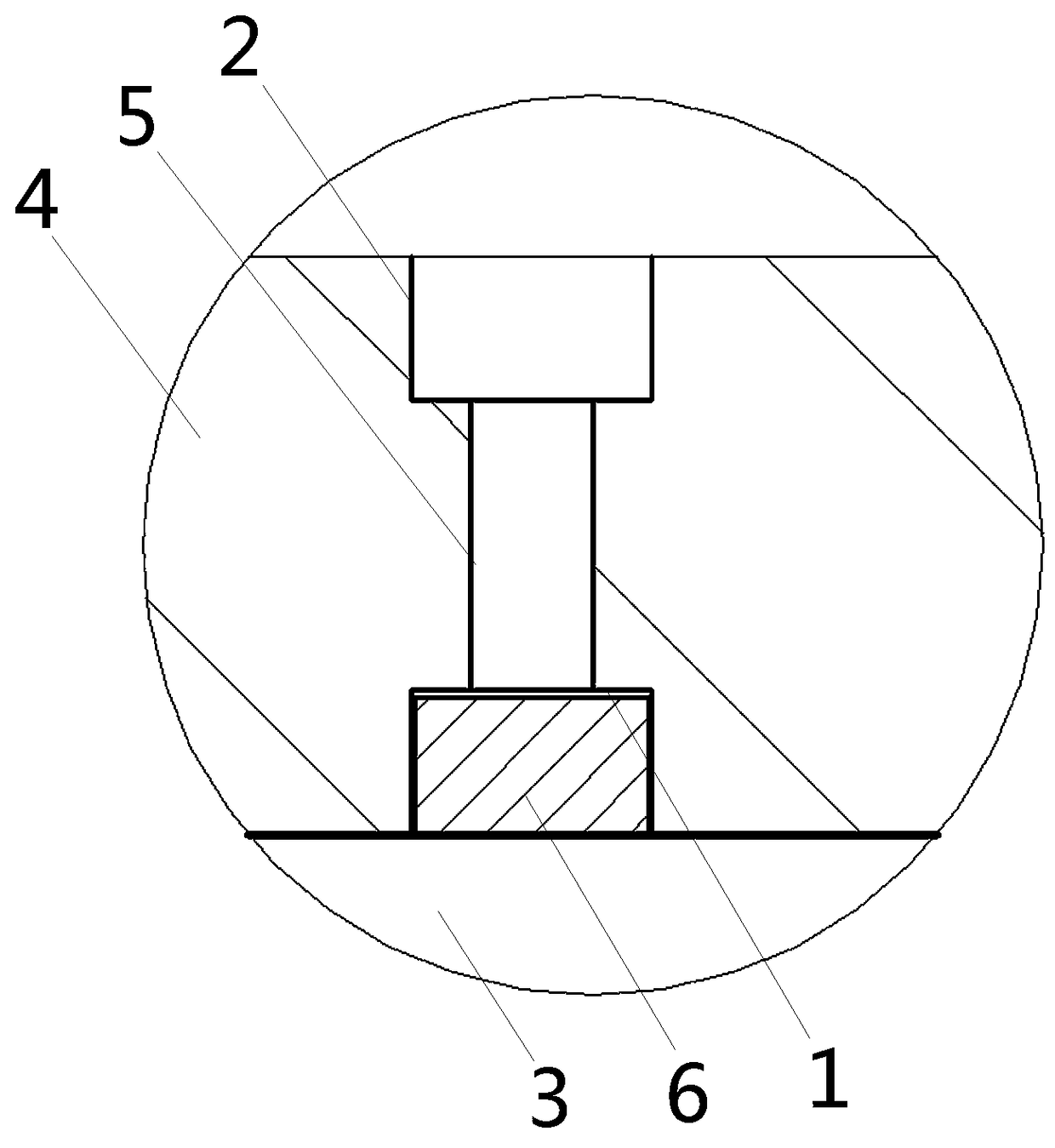

[0023] Embodiment 1, a prefabricated component embedded component, such as figure 1 As shown, it includes a lower embedded part 1 and an upper embedded part 2 , and the lower embedded part 1 is arranged between the fixed steel formwork table 3 and the lower side of the prefabricated component 4 . The lower embedded part 1 and the upper embedded part 2 are fixedly connected by a rigid rod 5, and the lower embedded part 1 and the upper embedded part 2 communicate up and down, and the lower embedded part 1 and the fixed steel formwork table The 3 are detachably connected by magnetic positioning. The upper and lower embedded parts are set, which saves the cumbersome operation of separately pre-embedding. It is neither necessary to open a reserved hole on the fixed steel formwork table 3, nor to set a boom on the side formwork table to carry out the upper embedded parts. installation location. The embedded parts can be positioned and embedded quickly, and the disassembly is conve...

Embodiment 2

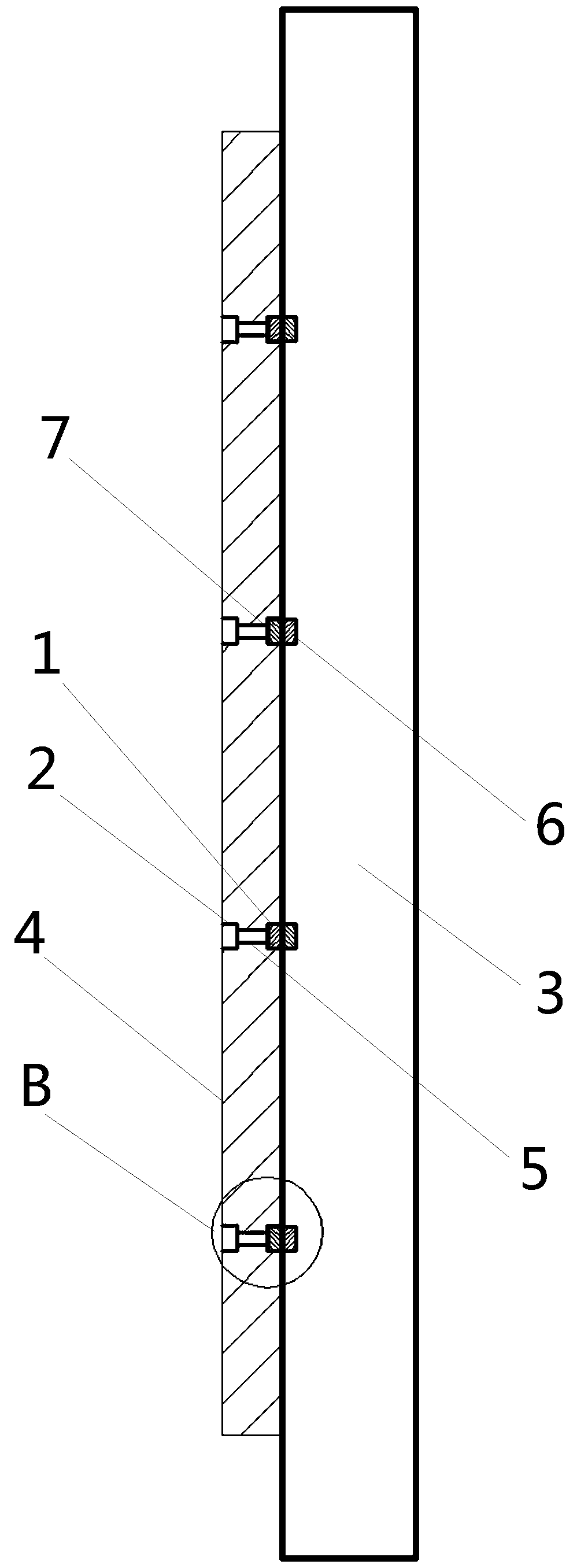

[0026] Embodiment 2, a prefabricated component embedded component, such as image 3 As shown, the magnetic positioning block 6 is arranged below the upper surface of the fixed steel formwork table 3, which can prevent the magnetic positioning block 6 from being polluted during the pouring stage of the prefabricated component, and can ensure good magnetic properties.

[0027] Further, as Figure 4 As shown, the upper surface of the fixed steel formwork table 3 is provided with a magnetic metal block 7 that cooperates with the magnetic positioning block 6, and the magnetic metal block 7 is engaged with the embedded part 1 on the lower side. Through the cooperation between the magnetic metal block 7 and the magnet positioning 6, and the cooperation between the magnetic metal block 7 and the lower embedded part 1, the stability of positioning can be fully guaranteed, and the pollution and damage to the magnetic positioning block can be avoided.

[0028] Other structures of this e...

Embodiment 3

[0029] Embodiment 3, a method for installing prefabricated component embedded components, comprising the following steps:

[0030] Step 1: Set the side form, place the magnetic positioning block 6 on the fixed steel formwork table 3 where the prefabricated component 4 will be embedded, and fix it with the fixed steel formwork table 3 by magnetic attraction;

[0031] Step 2: Magnetically fix the lower embedded part 1 with the magnetic positioning block 6 in step 1, then the upper embedded part 2 is fixed on the fixed steel formwork table 3 through the rigid rod 5 and the lower embedded part 1 ;

[0032] Step 3: Concrete pouring of the prefabricated component 4;

[0033] Step 4: After the concrete poured in step 3 is vibrated evenly and solidified, release the magnetic positioning between the magnetic positioning block 6 and the fixed steel formwork platform 3, and then remove the side mold of the prefabricated component 4, and then the magnetic suction The positioning block 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com