Micropore detection instrument

A detector and micro-hole technology, applied in the field of micro-hole detectors, can solve the problem of inability to determine the penetration state of each micro-hole on the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

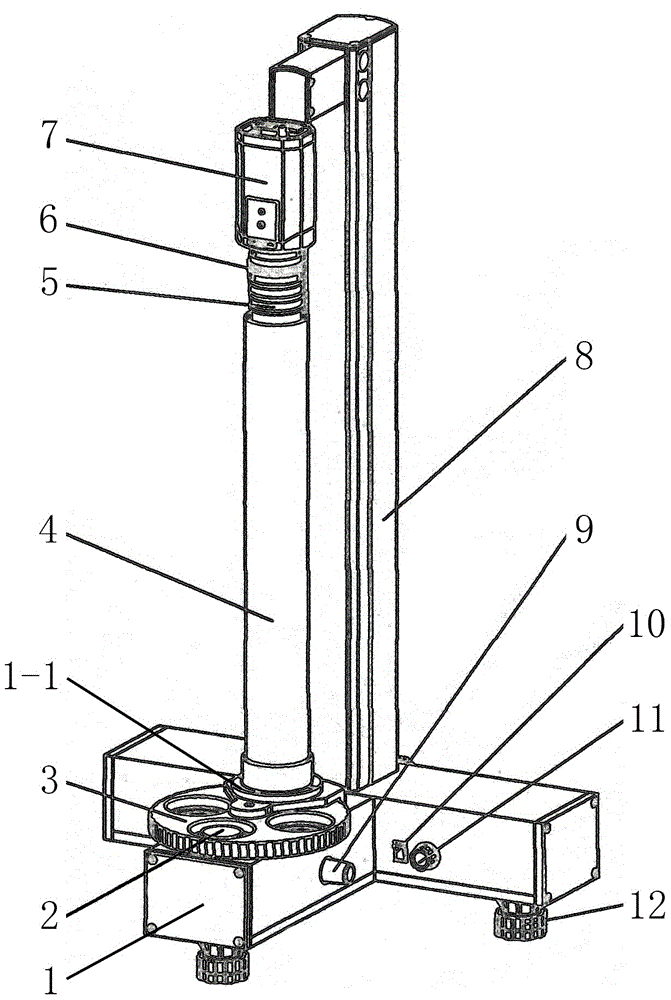

[0022] figure 1 The shown micropore detector mainly includes a base 1 , an object stage, a light-shielding tube 4 , a camera 7 , a frame 8 , a light source and a cooling device. The base 1 of this embodiment is a T-shaped shell, and three adjustment feet 12 are installed on the bottom of the base 1, and a frame 8 and a detection station frame 1-1 are fixed on the top of the base 1, and the detection station frame 1-1 1 and the base 1 is installed with a stage, the stage of this embodiment is a rotating stage 3 hinged between the detection station frame 1-1 and the base 1, the rotating stage 3 is provided with four A workpiece placement hole for placing the detected workpiece 2. The camera 7 is installed on the upper part of the erected frame 8, the lens of the camera 7 is connected with the light-shielding tube 4 between the detection station frame 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com