Micropore detection method based on luminous flux

A detection method and luminous flux technology, applied in the field of optical detection, can solve the problem of inability to determine the permeability state of micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

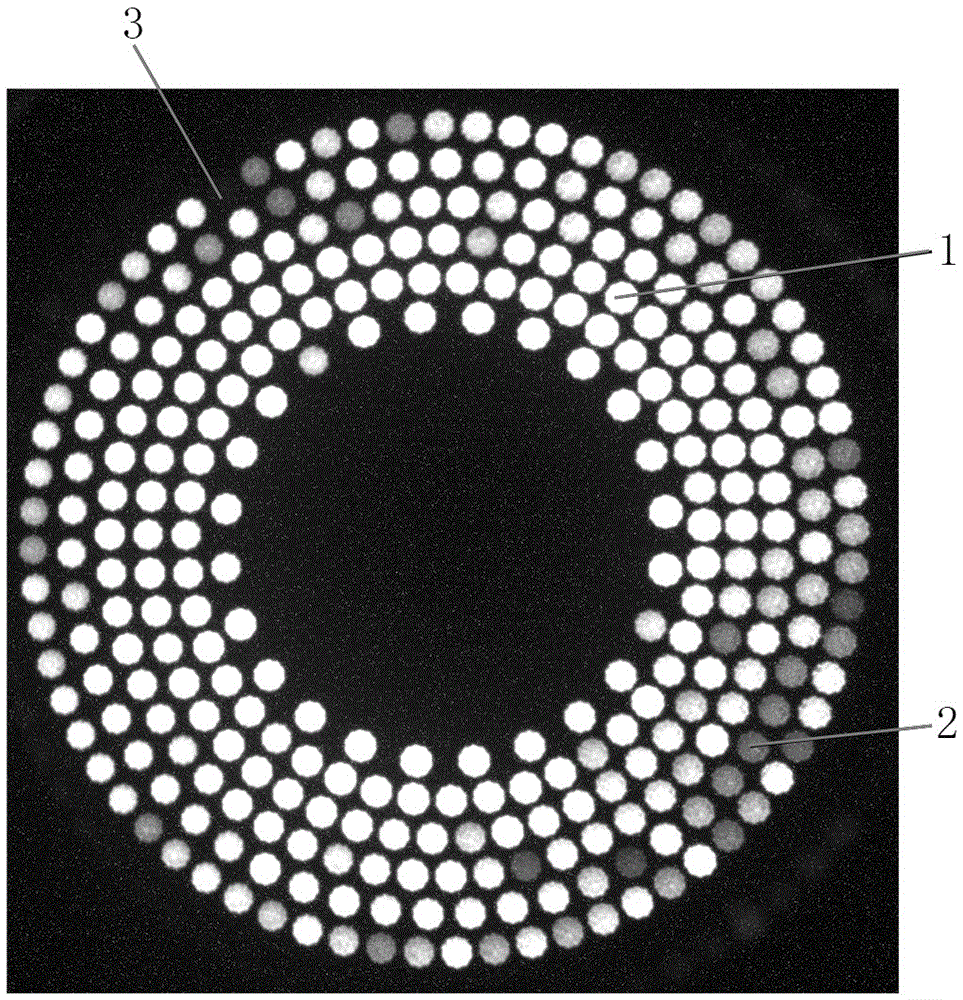

[0017] The detection object of this embodiment is a circular microhole workpiece with a diameter of 42.5 mm. Through the following microhole detection method based on luminous flux, all the microholes distributed in the φ42.5 mm circle are completely imaged at one time, and the diameter of each microhole is detected. transparent state. The CCD target surface size of the camera used in this embodiment is 1 / 2", the imaging magnification β=0.09× of the optical imaging system, and the minimum sensing illuminance of the camera is 0.001Lux; the optical imaging lens adopts a telecentric flat field lens , the focal length of the flat-field lens is 40.5mm, the working distance is 495mm, the numerical aperture is 0.025, and the edge distortion value is less than 0.014%; the optical path between the workpiece to be detected and the imaging lens of the camera is is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com