Laser direct writing energy correction method and device

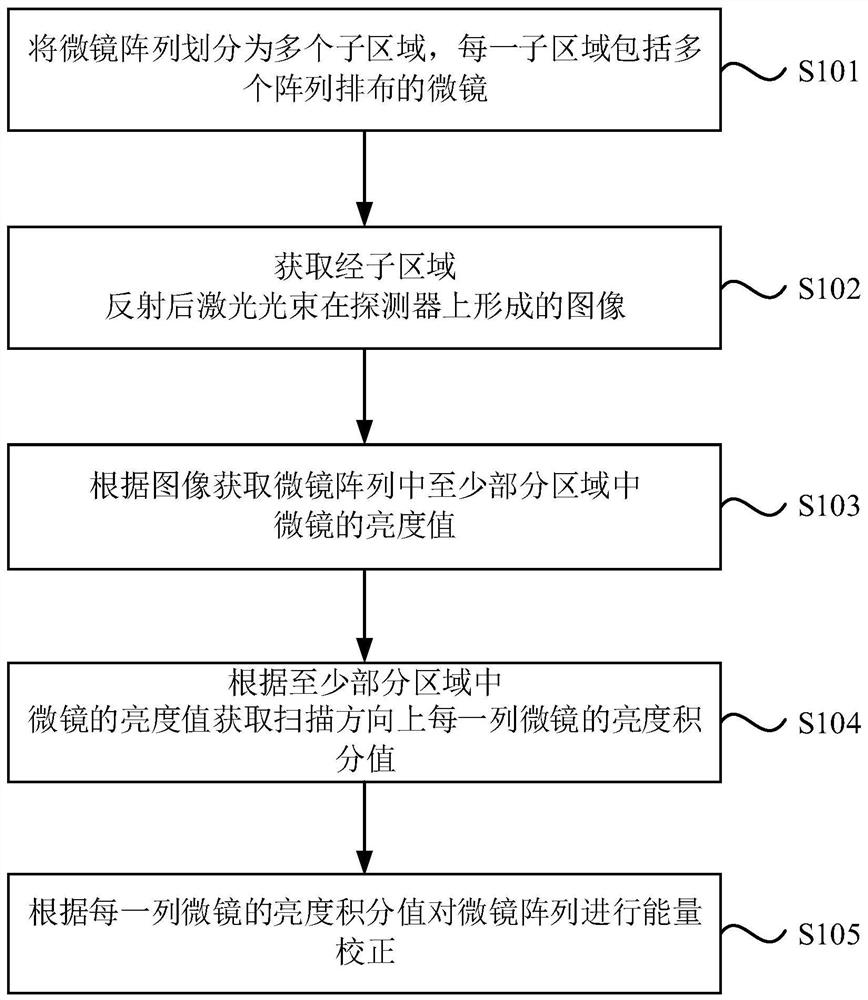

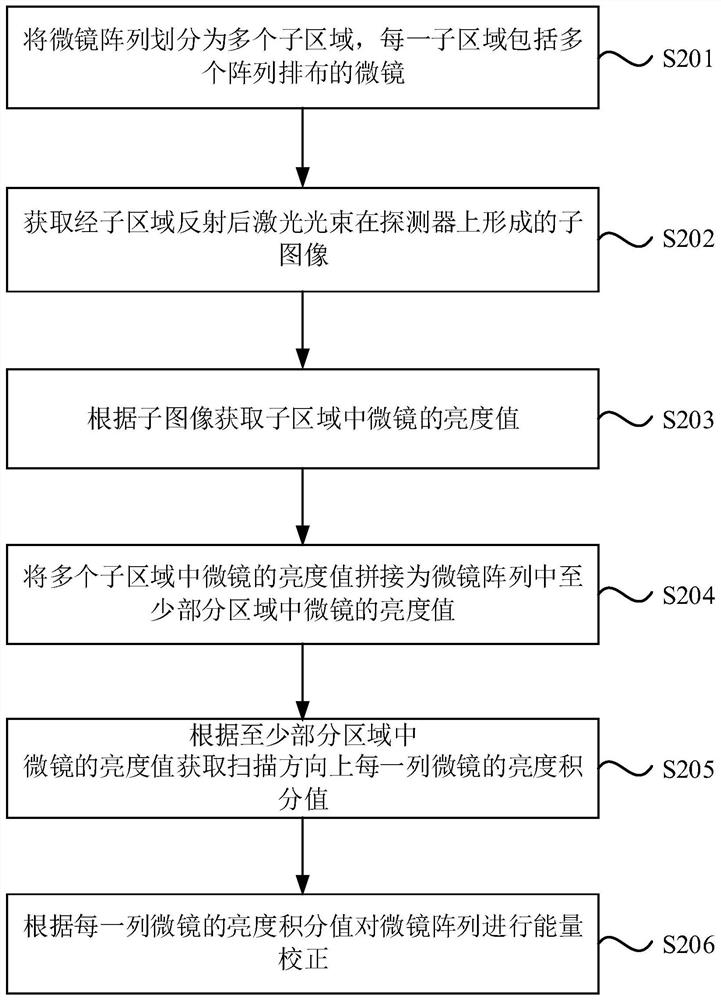

A technology of laser direct writing and energy, which is applied in the direction of exposure devices, optics, and optomechanical equipment in the photolithography process. It can solve the problems of not being able to obtain the reflected beam of the micromirror, and achieve the effect of solving the problem of brightness uniformity and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

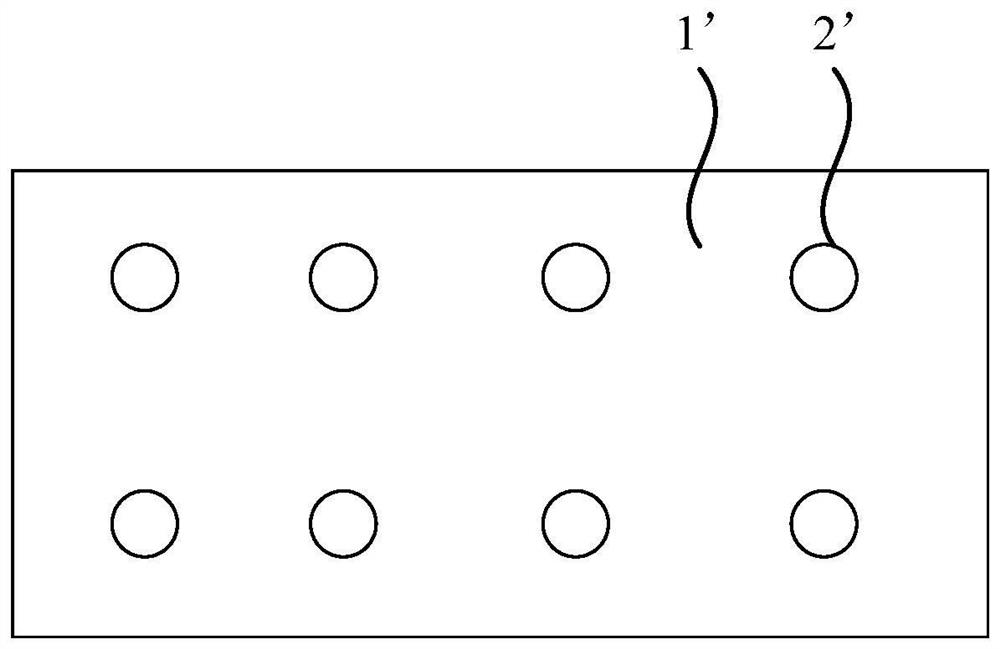

[0054]Laser direct writing uses a laser beam with variable intensity to perform variable dose exposure on the resist material on the surface of the substrate. After development, the required relief profile is formed on the surface of the resist layer. The laser direct writing imaging device can reflect the imaging through the micromirror array (that is, the digital micromirror device, also known as DMD). The modulated light beam is projected onto the photosensitive substrate to achieve the purpose of photolithogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com