Ultraviolet light LED generating device, processing method and ultraviolet light irradiating device

A technology of irradiation device and ultraviolet light, applied in the cooling/heating device of lighting device, lighting device, components of lighting device, etc., can solve the problems of large heat generation, short life, low ultraviolet energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

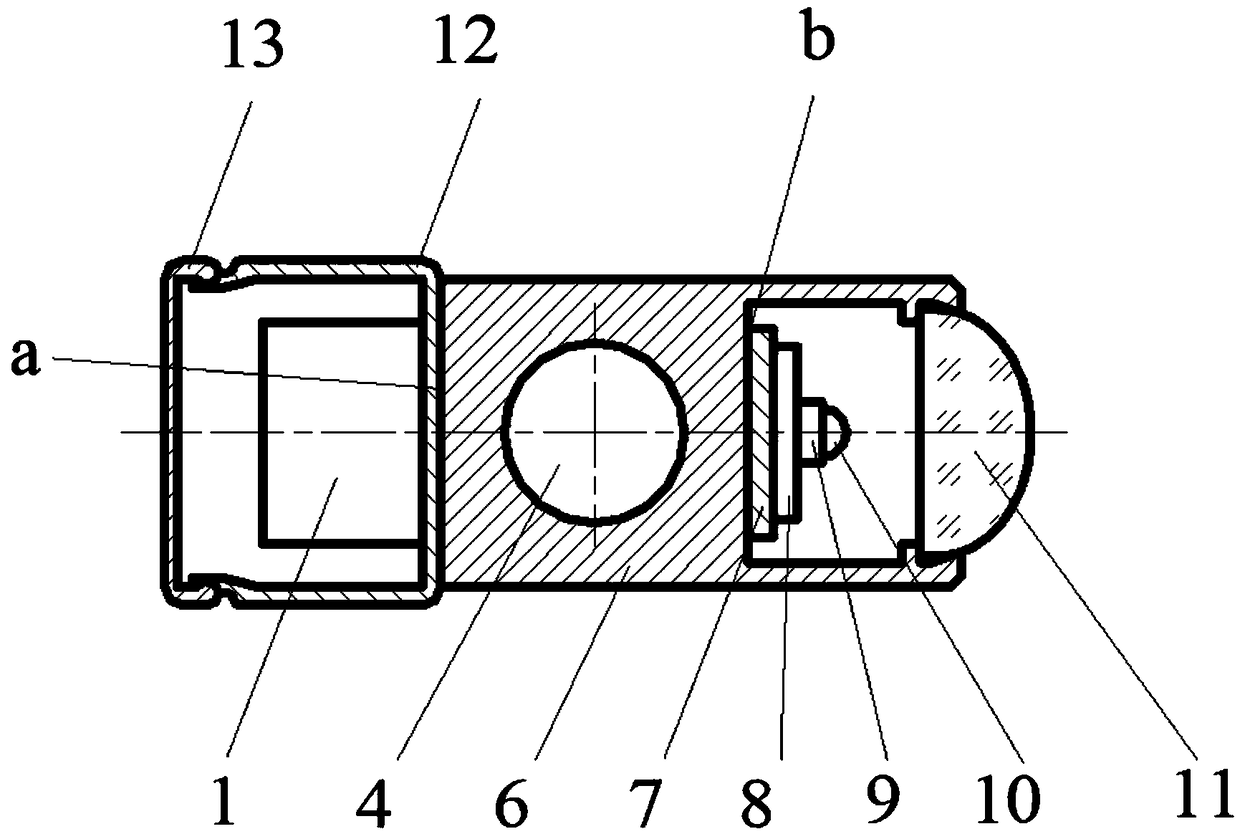

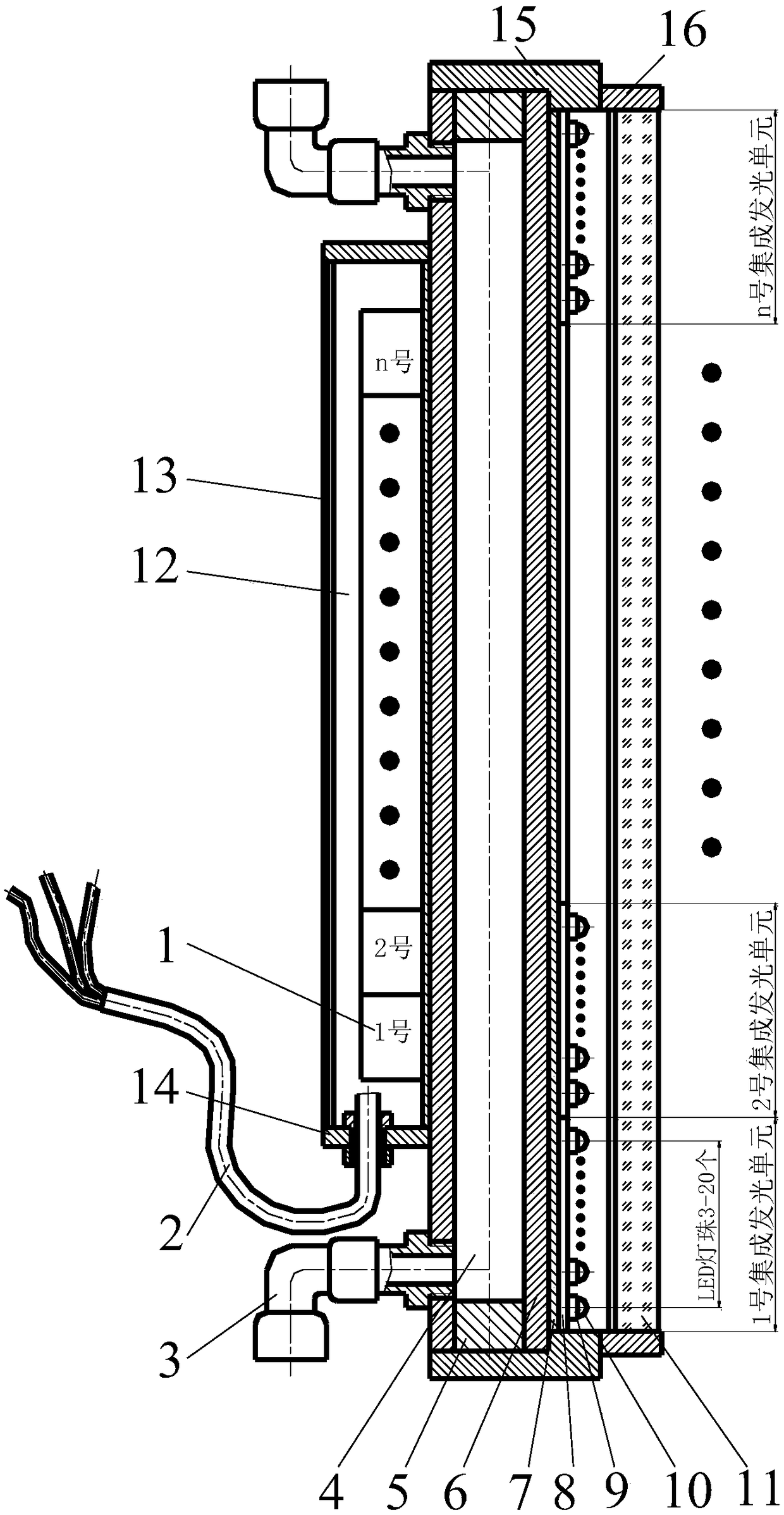

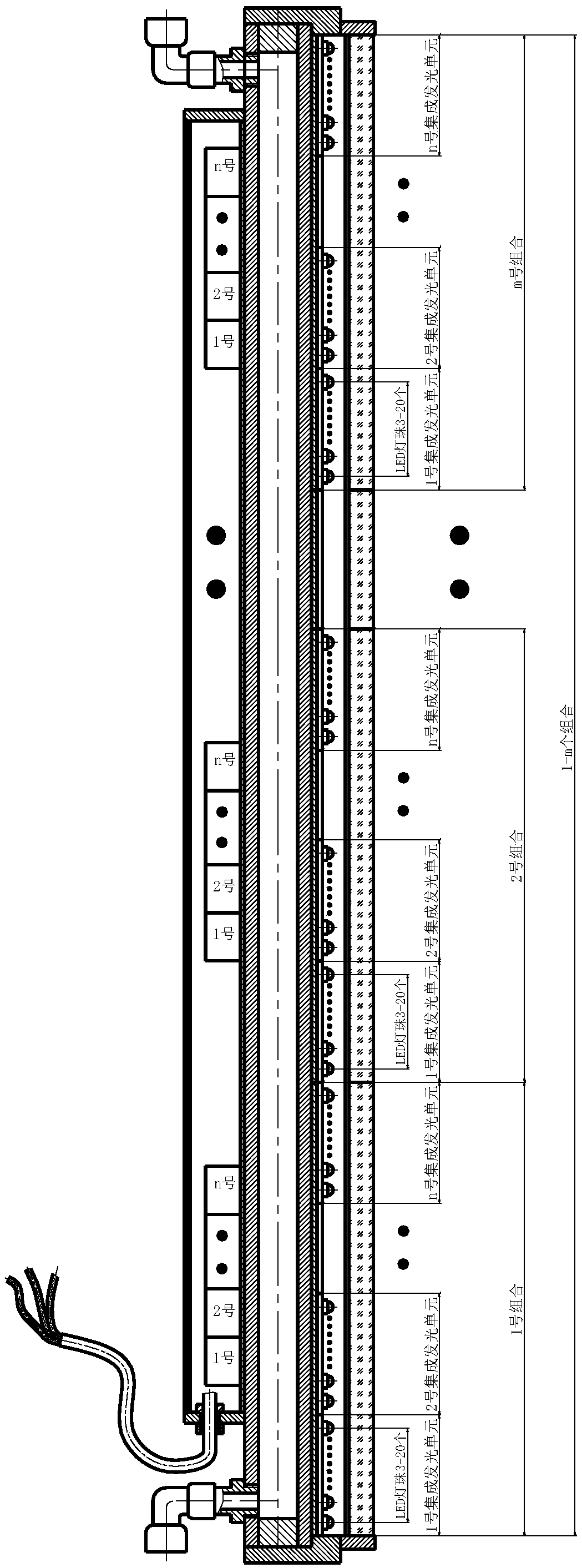

[0072] Such as Figure 1 to Figure 6 As shown, a UV LED generating device for irradiation crosslinking is composed of: a power module 1, a cooling seat 6, a substrate 7, an integrated circuit 8, a collimating lens 11 and an LED lamp bead. According to different needs, 3-20 of the LED lamp beads are welded to form an LED ultraviolet light emitting unit, and the LED ultraviolet light emitting unit is integrated with the substrate, and is connected to the power supply module through the power cord connected to power supply, each of the LED lamp beads is composed of a lens 10 and an LED chip 9, and according to the requirement of irradiating power, multiple groups of the LED ultraviolet light-emitting units can be integrated along the length direction on the substrate. The other side of the base plate is close to and fixed on the b-side of the cooling seat, and the number of the LED ultraviolet light-emitting units is the same as the number of the power modules, so that a group of...

no. 2 example

[0083] Such as Figure 7 with Figure 8 As shown, an openable and closable LED ultraviolet light irradiation device is composed of: an ultraviolet LED irradiation chamber 71, a transmission member 72 and a frame 73; the ultraviolet LED irradiation chamber is composed of a plurality of light-emitting components, The light-emitting component is assembled by a fixing piece and a plurality of LED light-emitting sources 78, and the LED light-emitting source is mainly composed of LED lamp beads 715, LED substrate 716, driving power 717, optical elements, and a cooling seat 714. The fixed parts at both ends are connected to realize the positioning and fixing of the LED light source, so that the LED light sources are axially parallel to each other, and there is an angle in the transverse direction, and the beams emitted are all irradiated to the same axis, which is defined as OO. Multiple LED light-emitting components The way to combine the ultraviolet LED irradiation cavity is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com