Positioning and clamping mechanism of welding fixture of automobile stamping piece

A technology for automotive stamping parts and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effects of improving production efficiency, shortening action time, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

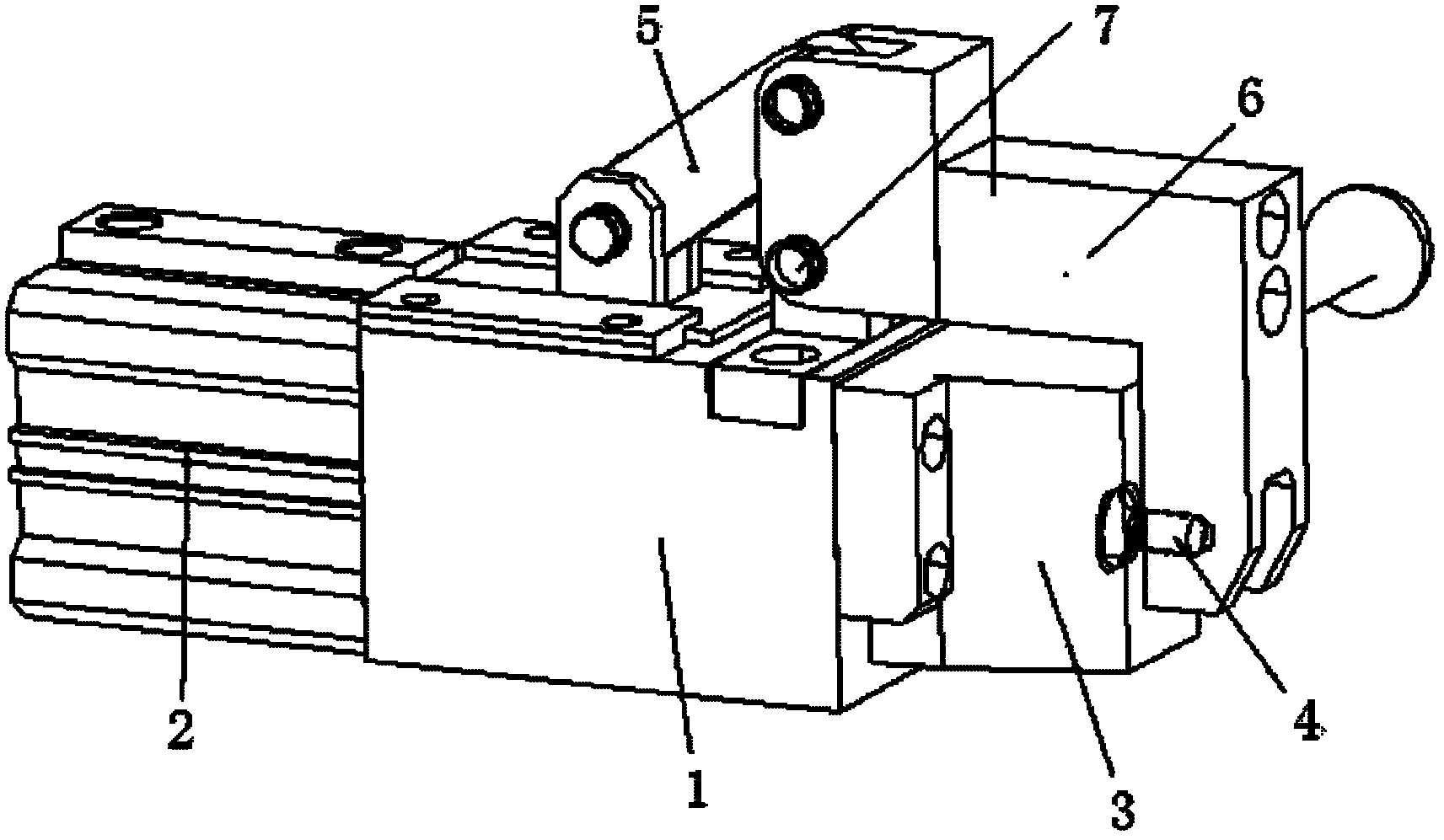

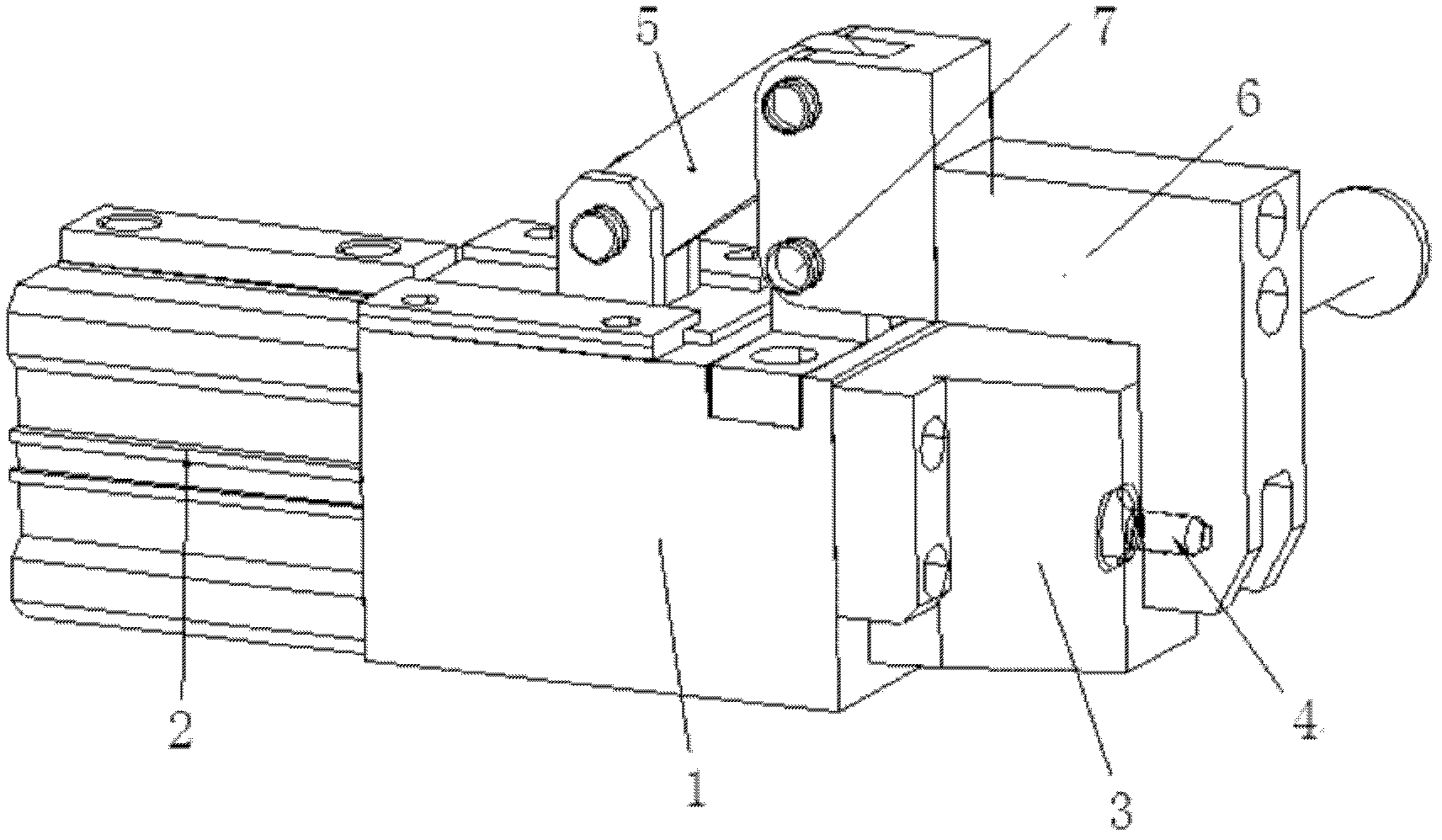

[0014] see figure 1 , the positioning and clamping mechanism of the automobile stamping parts welding fixture, including a mounting seat 1 installed on the bottom plate of the welding fixture, a locking cylinder 2 is installed on one end of the mounting seat 1, and a support block is fixed on the other end of the mounting seat 1 3. The piston rod of the locking cylinder 2 passes through the mounting seat 1 and the support block 3. The protruding end of the piston rod of the locking cylinder 2 is fixed with a positioning pin 4 positioned toward the positioning hole of the stamping part. The mounting seat 1. The upper end is hinged 7 with a bent pressure block 6. The lower end of the pressure block 6 is buckled outside the support block 3. The piston rod of the locking cylinder 2 is also fixed with a hinge mechanism 5. The hinge Mechanism 5 is hinged with the upper end of bent shape briquetting block 6 by connecting rod. There is a bar-shaped groove on the mounting base 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com