Kiln head cover of rotary kiln

A technology of kiln head cover and rotary kiln, which is applied in the field of rotary kiln and can solve the problems such as the inability of the maintenance door to meet the maintenance needs and the limited opening size of the maintenance door.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

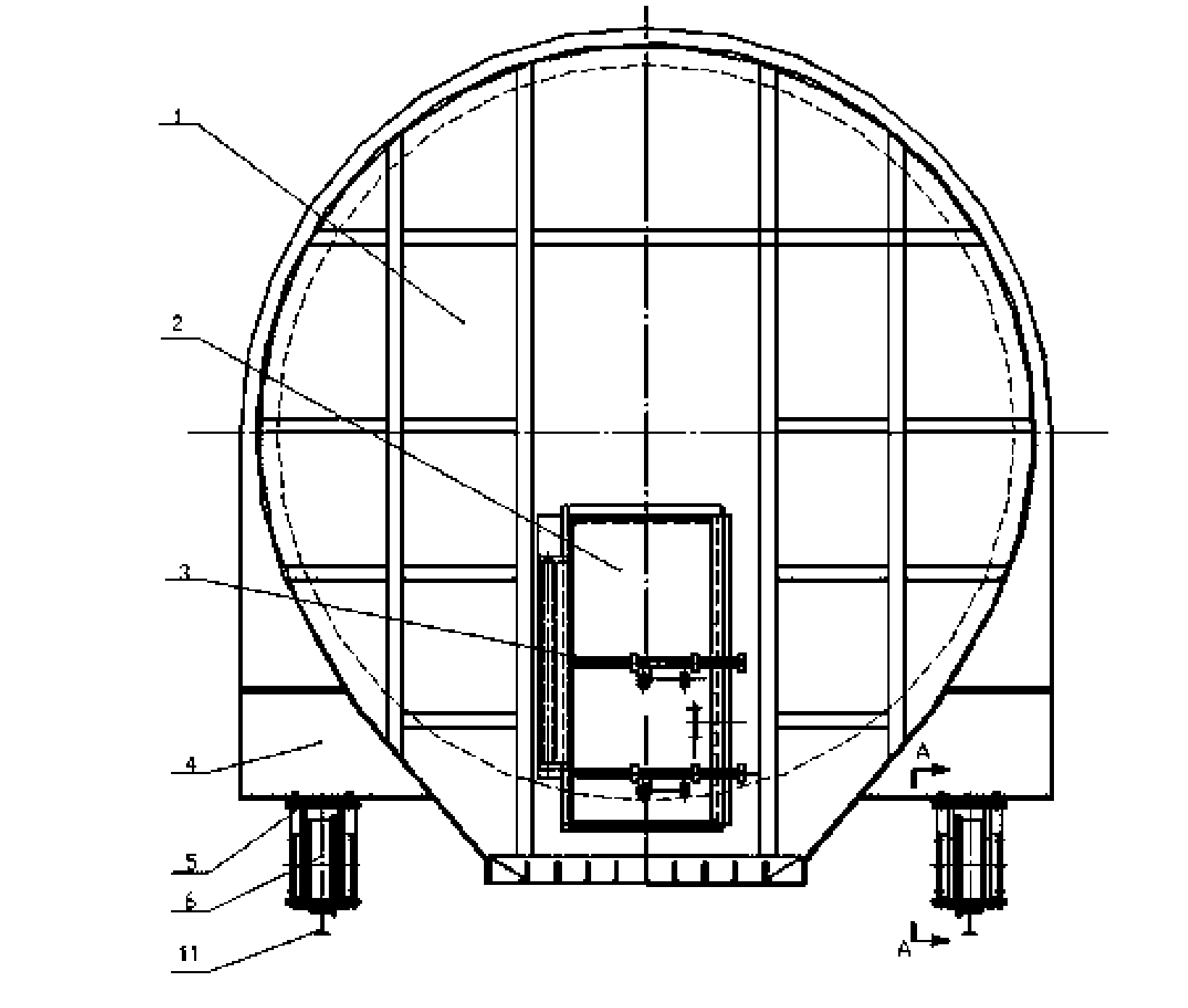

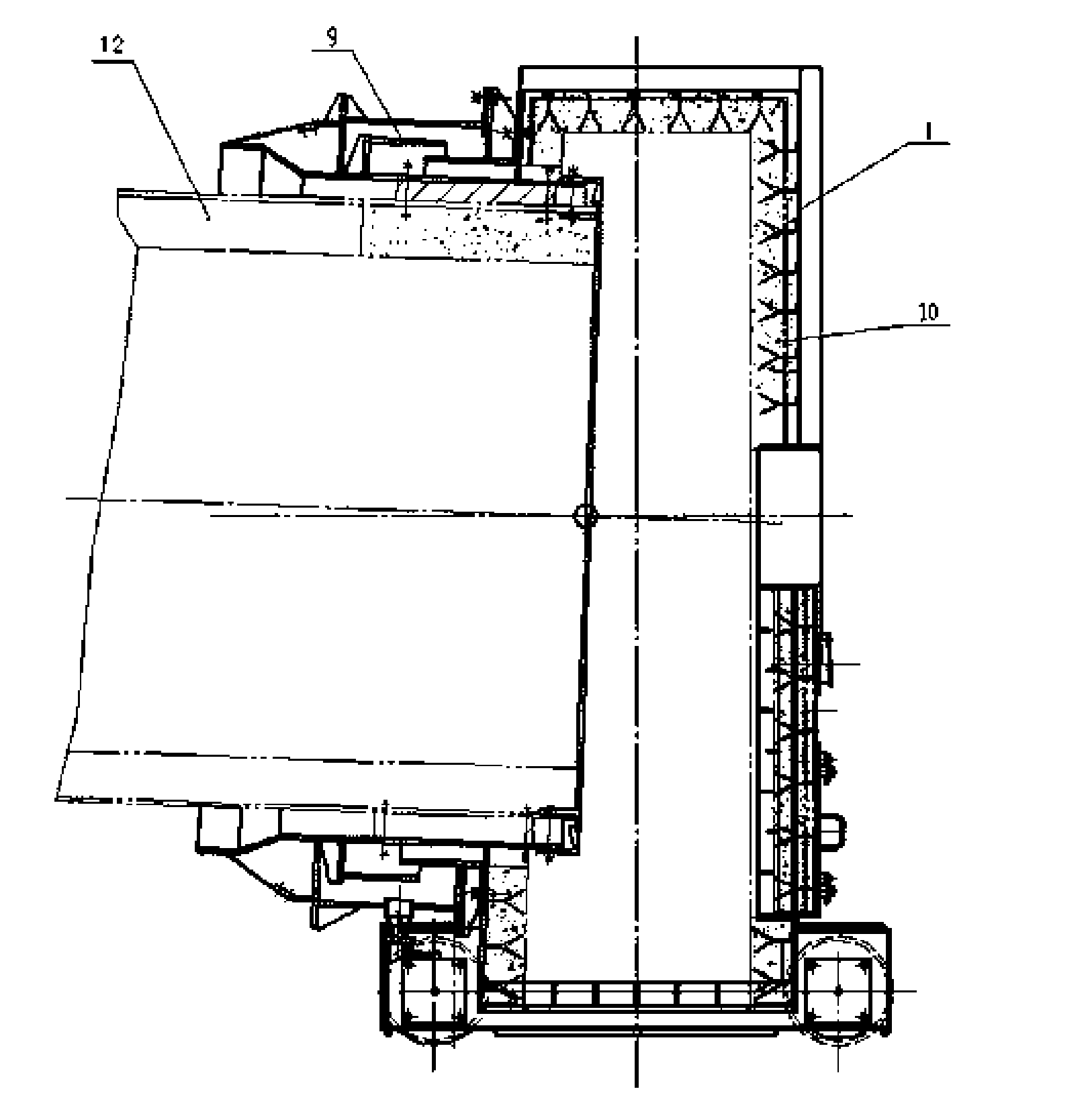

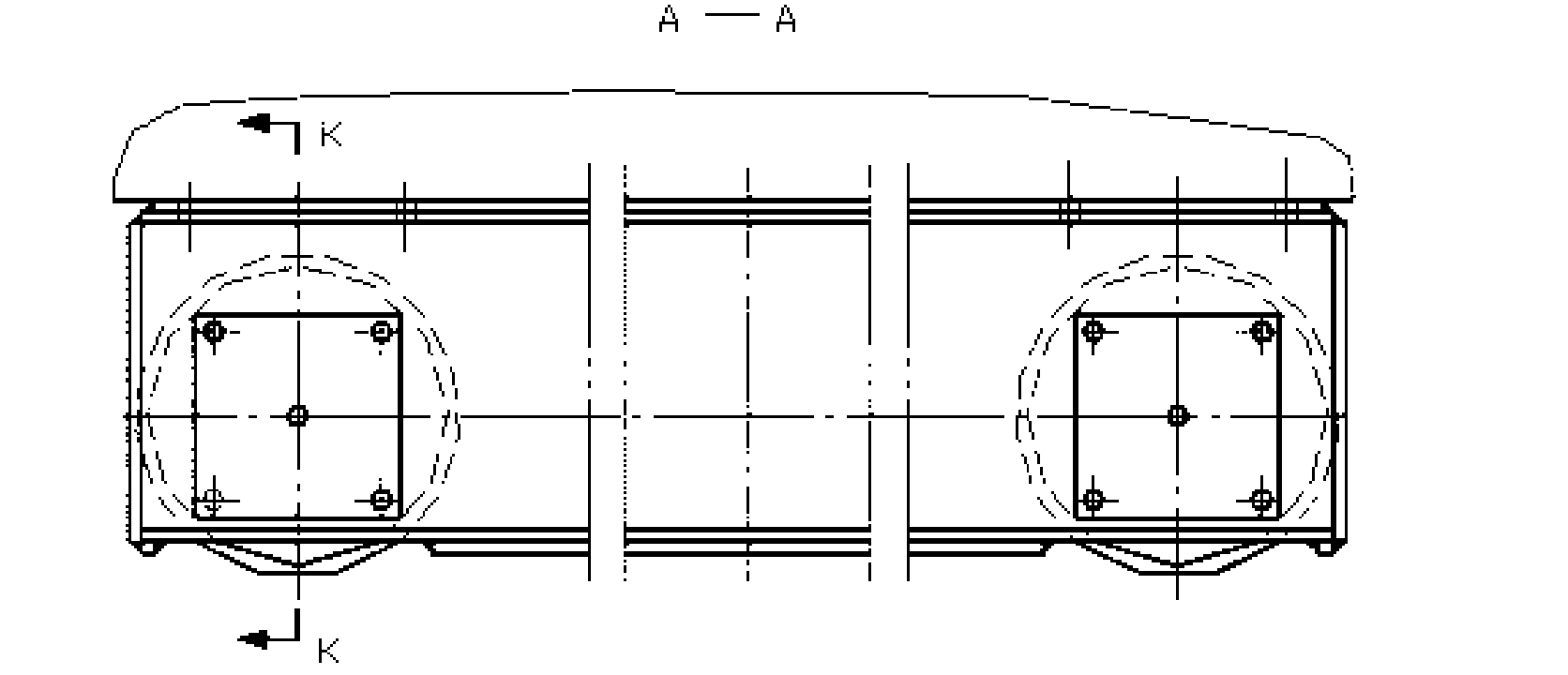

[0014] Embodiment 1 of the present invention: as figure 1 , figure 2 As shown, the rotary kiln head cover of the present invention includes a kiln head sealing device 9 welded together with the kiln shell 12, and the kiln head cover body 1 is connected to the other side of the kiln head sealing device 9, and the kiln head cover body 1 The inner side is provided with a refractory material lining 10, and the front is provided with a rectangular cover door 2. A door bolt 3 is installed on the cover door 2. The kiln head cover body 1 and the kiln head sealing device 9 can be disengaged. The both sides of 1 are equipped with wheel support 4, and the below of wheel support 4 is provided with wheel set, and the below wheel set is provided with steel rail 11. Each wheel set includes at least two wheels 6 , and the wheels 6 are fixed on the vehicle frame 5 through the wheel axle 7 . The wheel shaft 7 is supported and coupled on the vehicle frame 5 through the bearing 8 .

[0015] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com