Method for pouring ABR (Acrylate Butadience Rubber) reaction tank baffle

A technology of baffles and reaction pools, which is applied in the processing of building materials, construction, building structures, etc., can solve problems affecting the effect of wastewater treatment, affecting the structure of baffles, and corrosion of steel bars, so as to ensure the effect of sewage treatment, Good molding quality and anti-deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

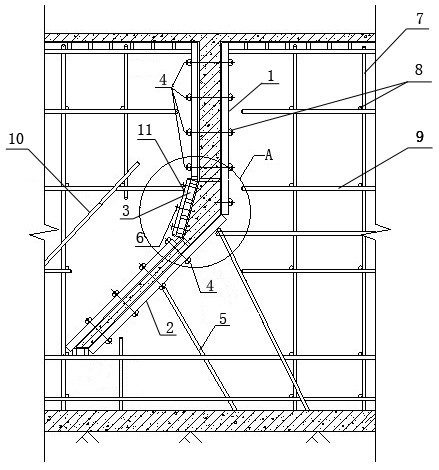

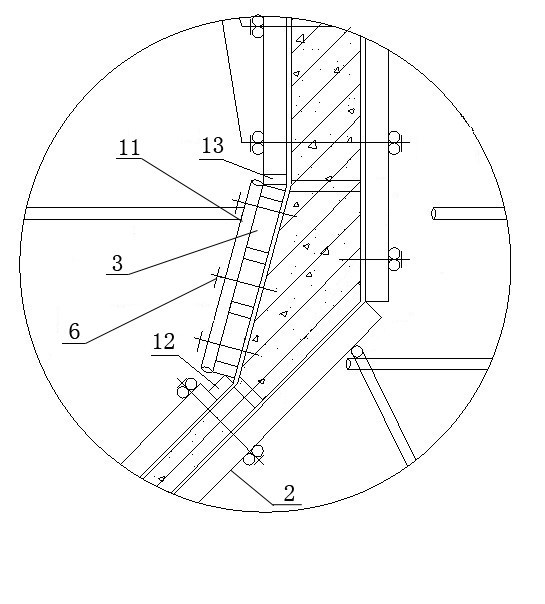

[0031] The present invention will be further described below in combination with specific embodiments.

[0032] The method for pouring ABR reaction tank baffles comprises the steps:

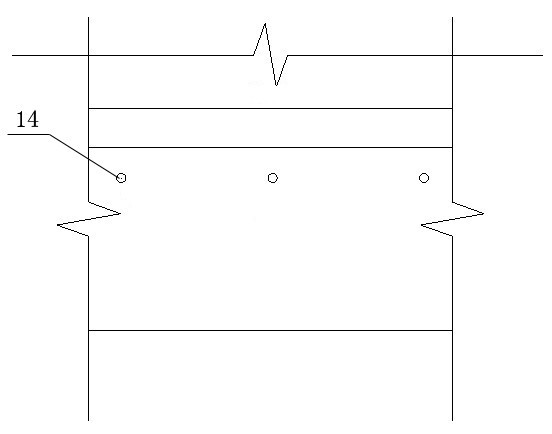

[0033] 1) Binding of steel mesh: Bind the double-layer steel mesh with steel bars at the beam body, plate body and armpit of the baffle with a horizontal spacing of 140 mm and a longitudinal spacing of 120 mm; the steel mesh must be bound strictly according to this spacing to ensure that Under the premise of satisfying the structural bearing capacity, prevent stones from getting stuck in the steel bars, and avoid quality defects such as leaking stones and holes; all steel bars in the steel mesh are fully tied to avoid loosening of the steel bars due to the vibration of the vibrating rod. The steel stirrups are bound and positioned between the double-layer steel mesh, and the stirrup is firmly bound to the steel mesh to ensure the distance between the double-layer steel mesh and the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com