Direct-current brushless vacuum pump

A brushless DC, vacuum pump technology, applied in the field of air compressors, can solve the problems of heavy metal material, complex manufacturing process, low production efficiency, etc., and achieve the effects of weight reduction, simple manufacturing process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

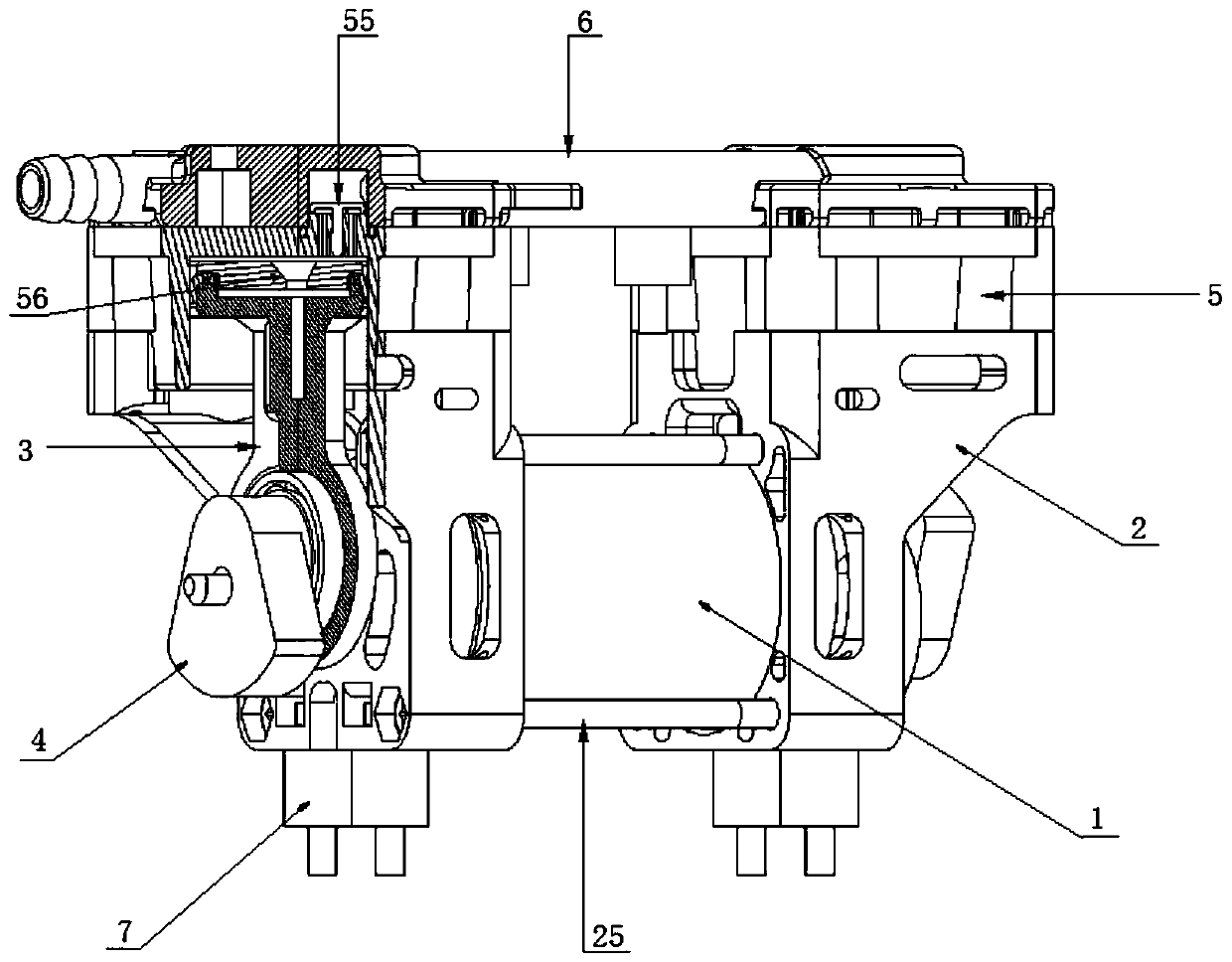

[0030] Examples, combined with Figure 1~6 , a DC brushless vacuum pump, comprising a motor 1, a casing 2, a cylinder connecting rod 3, an eccentric wheel 4, a cylinder 5 and a cylinder head 6, the two ends of the motor 1 are provided with a casing 2, and the cylinder connecting rod 3 and eccentric wheel 4 are sequentially connected symmetrically to both ends of the central axis of the motor 1 and close to the outside of the box body 2 , the upper end of the box body 2 is connected to a cylinder 5 , and the upper end of the cylinder 5 is covered with a cylinder head 6 .

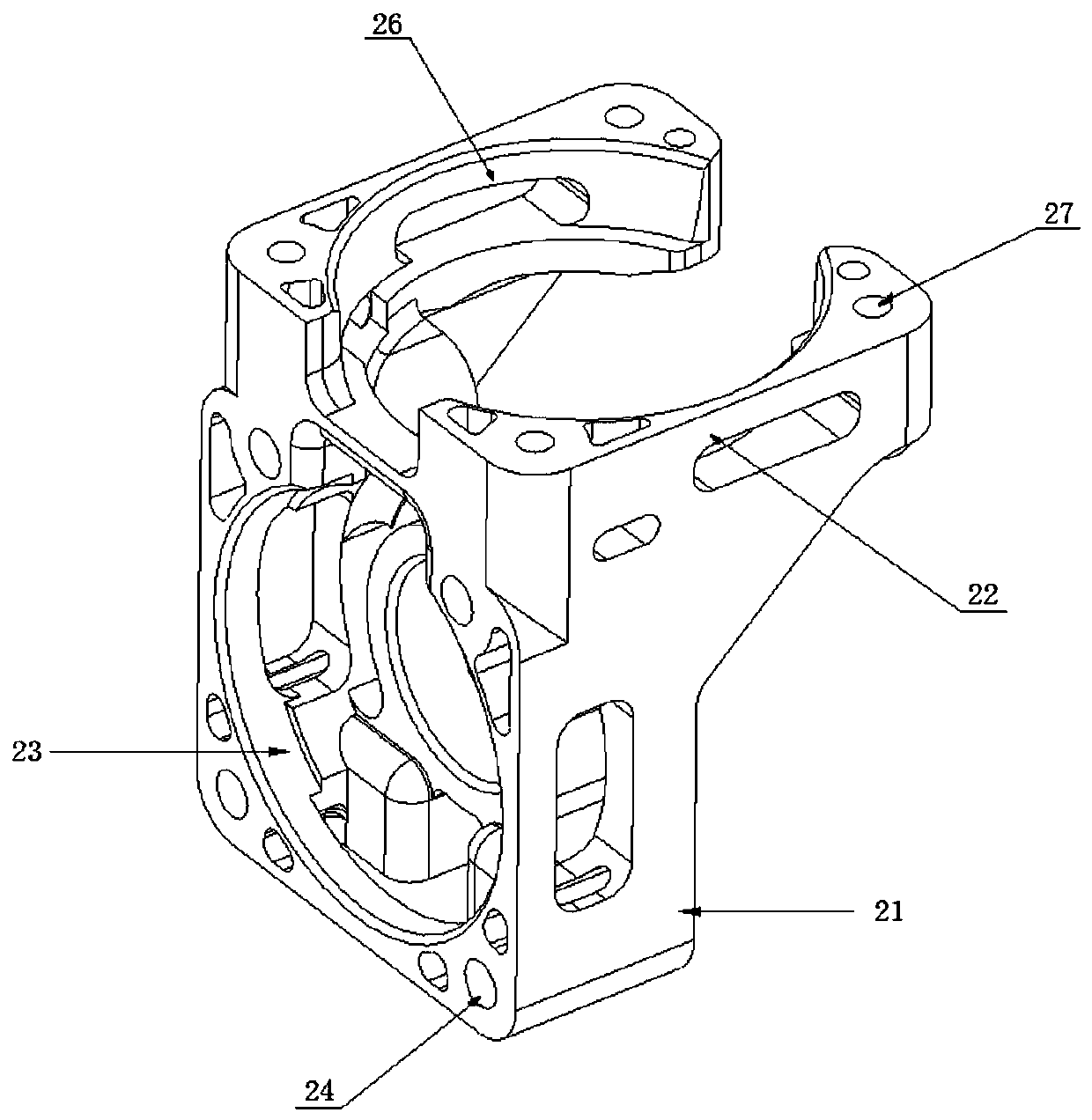

[0031] Described casing 2 comprises motor holder 21 and cylinder holder 22, and described motor holder 21 is a vertical cube, and described motor holder 21 center is provided with motor holder hole 23, and the aperture of described motor holder hole 23 is equal to The outer diameter of the motor 1, the side of the motor holder 21 is provided with a first screw hole 24, the first screw hole 24 is four, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com