Hydraulic inner mould of single-wire box girder

A box girder and hydraulic technology, applied in the direction of molds, etc., can solve the problems of increasing labor intensity, affecting the efficiency of beam making, and difficult to meet the requirements of the stability of prefabricated box girder, achieving fast demoulding speed, convenient use and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the device will be described in detail below in conjunction with the accompanying drawings.

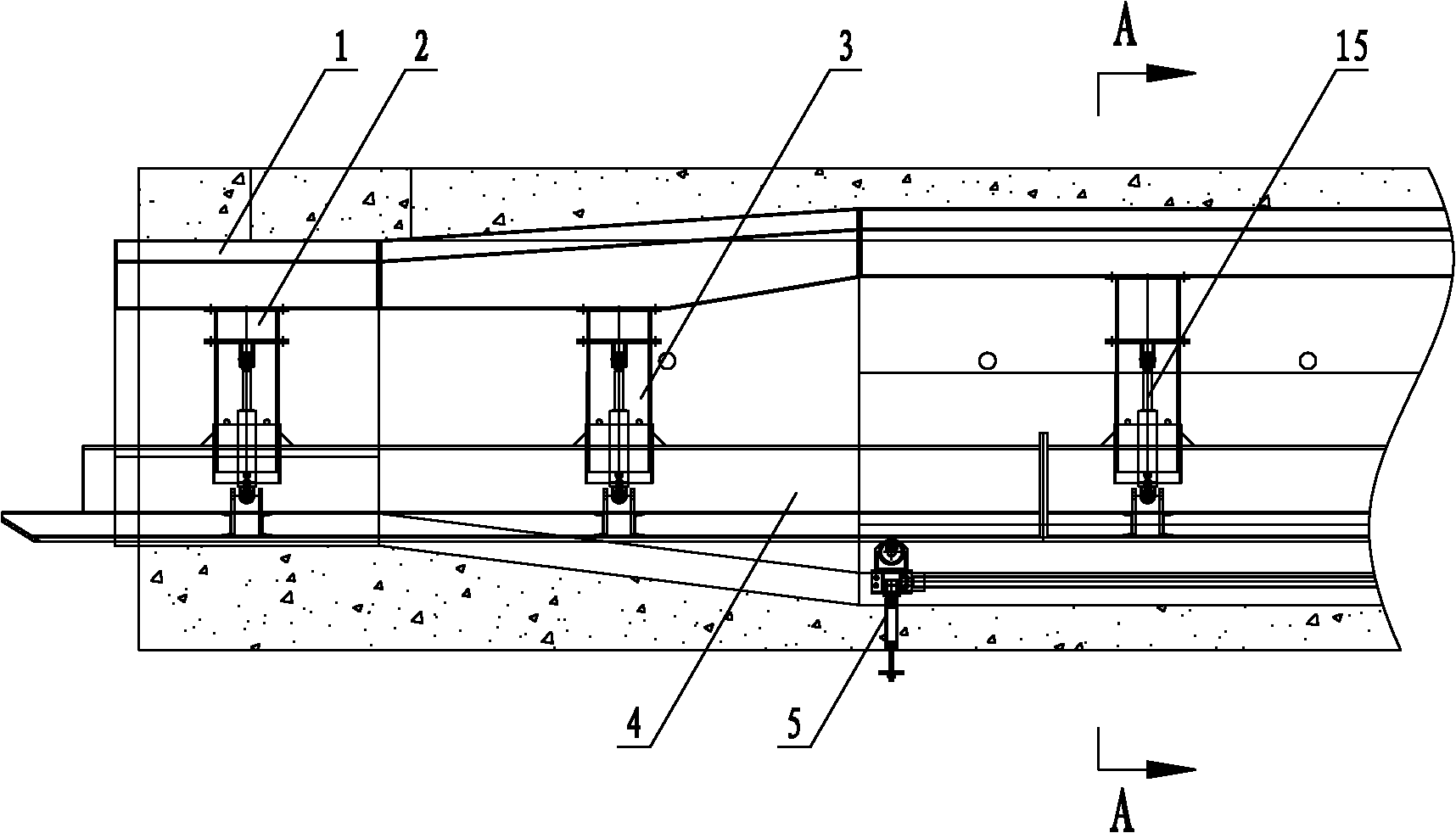

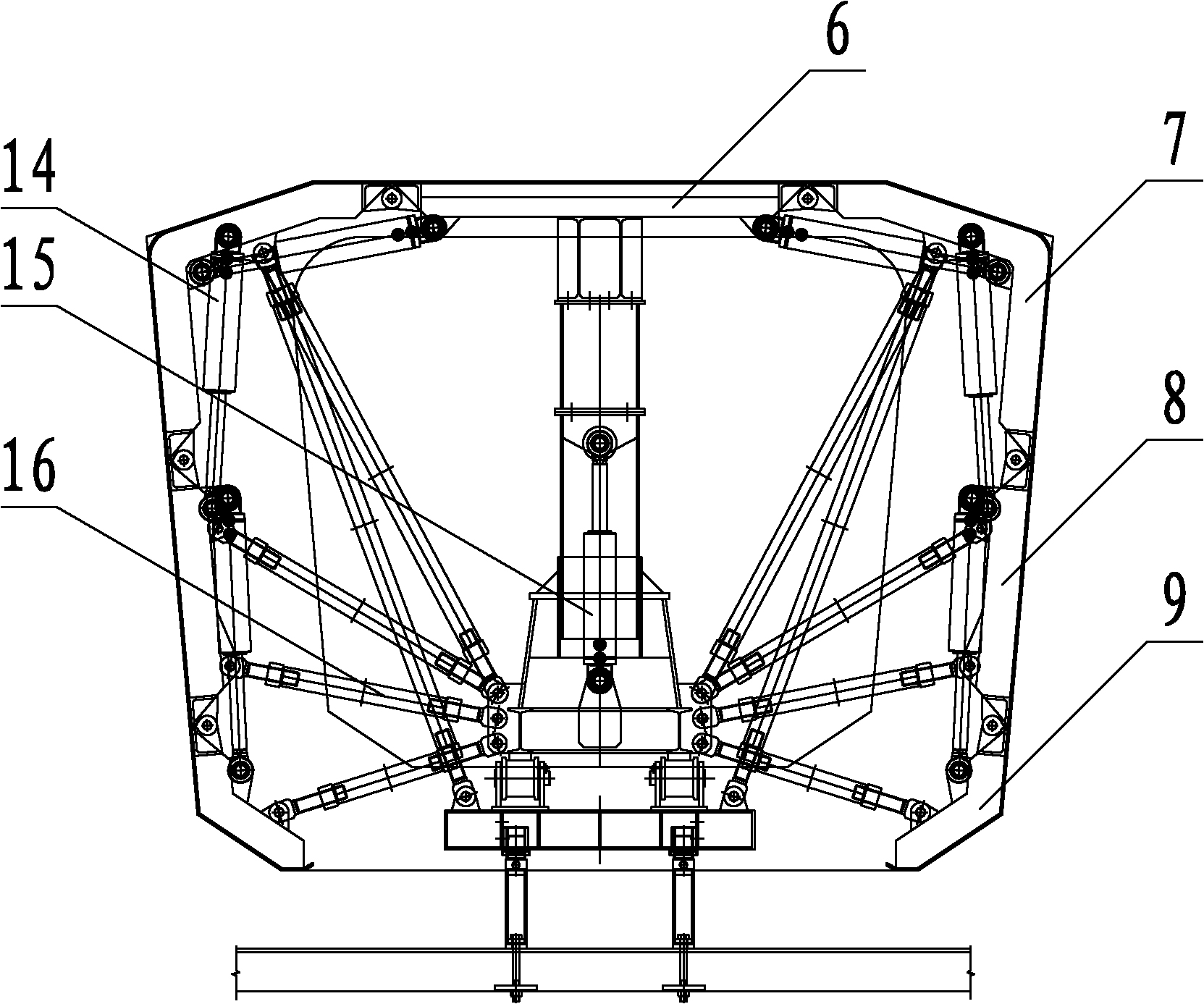

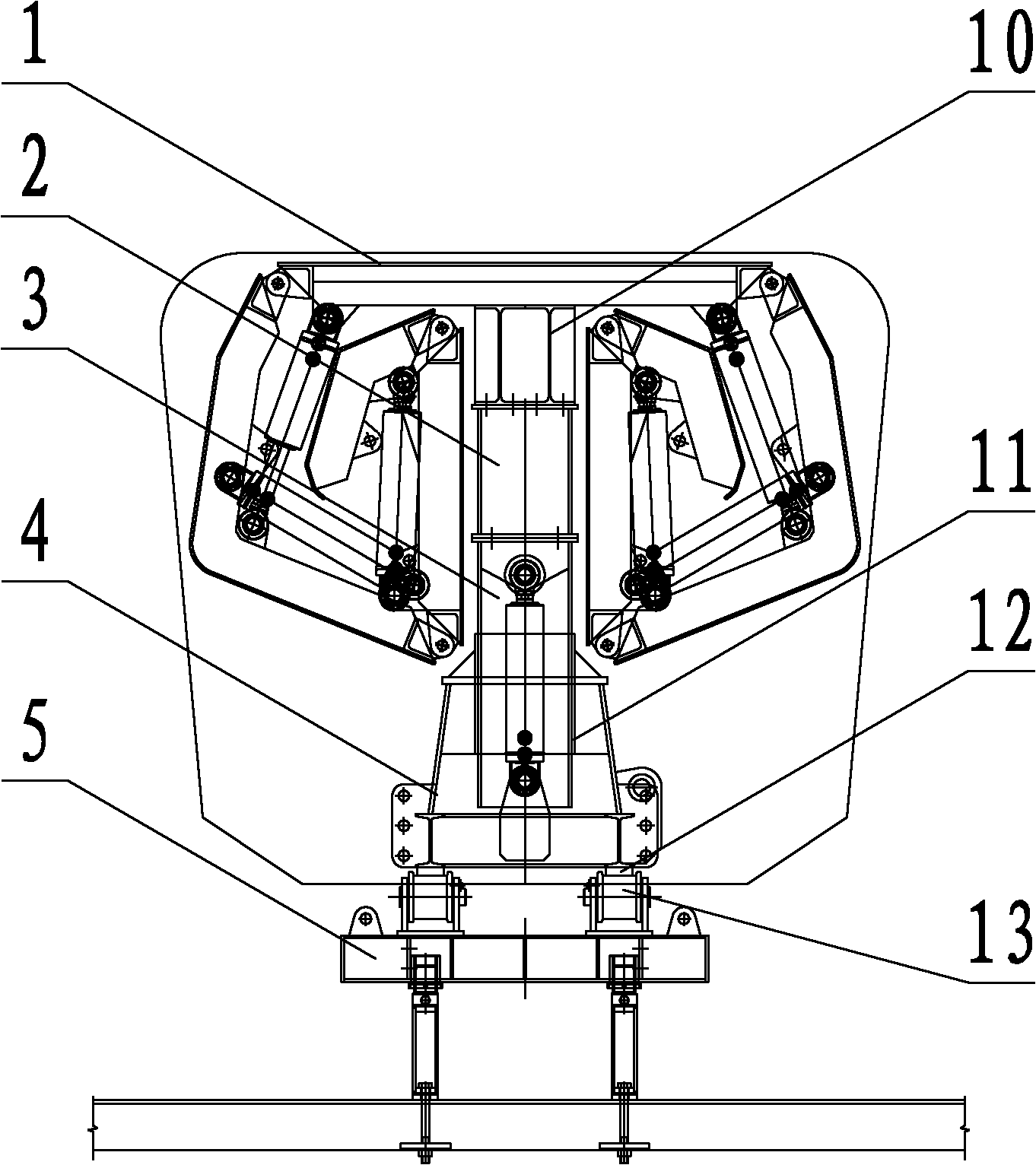

[0015] The single-line box girder hydraulic internal mold provided by the present invention includes a formwork 1, an adjustment column 2, a guide column 3, a main beam 4, a supporting base 5, a lateral oil cylinder 14, a jacking oil cylinder 15 and a telescopic strut 16, wherein the main beam Guide sleeve 11 is installed in 4, and guide rail 12 is equipped with at the bottom of girder 4, and anti-roller 13 is installed on support base 5. The formwork 1 is connected with the guide column 3 through the adjustment column 2. The guide column 3 is installed in the guide sleeve 11 in the main beam 4 and can slide in the guide sleeve 11. The main beam 4 is placed on the support base 5 through the guide rail 12 at the bottom. On the anti-roller 13 and can slide on the anti-roller 13, the internal mold is dragged out of the beam body, and the jacking cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com