Traceless machining process for large arc surface of stainless steel vacuum water cup

A processing technology and stainless steel technology, which is applied in the field of non-marking processing technology of large circular arc surface of stainless steel vacuum water cup, can solve the problems of short molding time, affecting the use feeling, large deformation, etc., to improve the service life, wide application range and molding quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

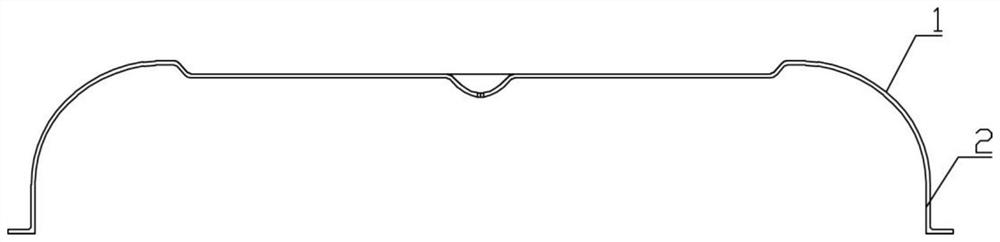

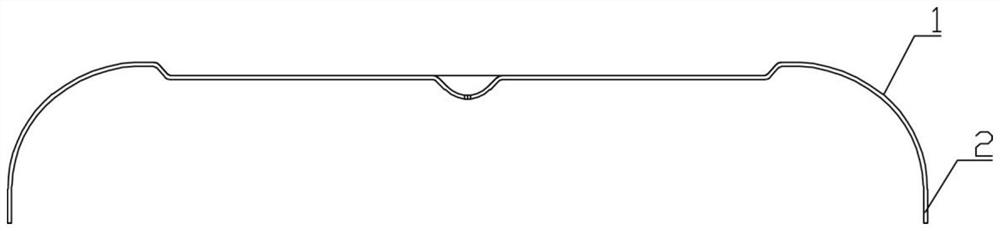

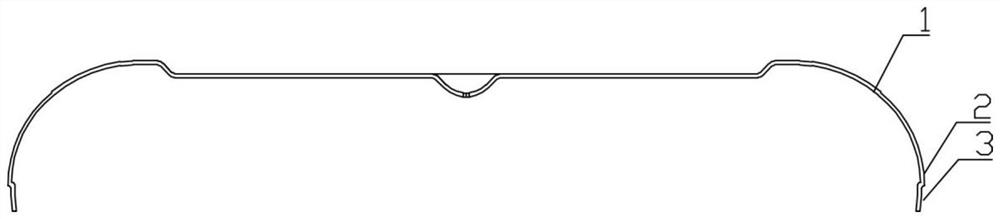

Image

Examples

Embodiment 1

[0039] Preparation of nanocomposite fibers

[0040] Preparation of formylated microcrystalline cellulose: according to the solid-to-liquid ratio of 150g / L, weigh the microcrystalline cellulose, stir and disperse it in distilled water, add sodium periodate 0.9 times the mass of microcrystalline cellulose, and put it at 40°C Stir and react in the dark for 8 hours to obtain a suspension of aldylated microcrystalline cellulose;

[0041] Preparation of spinning solution: Measure tetrahydrofuran and N', N'-dimethylformamide respectively according to the volume ratio of 95:5, stir and mix evenly, then add EPDM rubber particles, heat to 60°C, keep stirring for 11 hours , add aldehyde-based microcrystalline cellulose suspension 0.12 times the mass of EPDM rubber, raise the temperature to 80°C, stir and mix at a speed of 300r / min for 2h, and cool naturally to room temperature to obtain the mass fraction of EPDM rubber It is 8% spinning dope.

Embodiment 2

[0054] Preparation of nanocomposite fibers

[0055] Preparation of modified chitosan

[0056] Preparation of aldylated microcrystalline cellulose: according to the solid-to-liquid ratio of 120g / L, weigh the microcrystalline cellulose, stir and disperse it in distilled water, add sodium periodate 0.9 times the mass of the microcrystalline cellulose, and place it at 40°C Stir and react in the dark for 10 hours to obtain a suspension of aldylated microcrystalline cellulose;

[0057] Preparation of spinning solution: Measure tetrahydrofuran and N', N'-dimethylformamide respectively according to the volume ratio of 95:5, stir and mix evenly, then add EPDM rubber particles, heat to 55°C, keep stirring for 12 hours , add aldehyde-based microcrystalline cellulose suspension of 0.1 times the mass of EPDM rubber, raise the temperature to 80°C, stir and mix at a speed of 400r / min for 2 hours, and naturally cool to room temperature to obtain the mass fraction of EPDM rubber It is 9% spi...

Embodiment 3

[0070] Preparation of nanocomposite fibers

[0071] Preparation of formylated microcrystalline cellulose: according to the solid-to-liquid ratio of 140g / L, weigh the microcrystalline cellulose, stir and disperse it in distilled water, add sodium periodate 0.9 times the mass of the microcrystalline cellulose, and place at 40°C Stir and react in the dark for 12 hours to obtain an aldylated microcrystalline cellulose suspension;

[0072] Preparation of spinning solution: measure tetrahydrofuran and N', N'-dimethylformamide respectively according to the volume ratio of 95:5, stir and mix evenly, then add EPDM rubber particles, heat to 60°C, keep stirring for 10h , add aldehyde-based microcrystalline cellulose suspension 0.11 times the mass of EPDM rubber, raise the temperature to 85°C, stir and mix at a speed of 500r / min for 1h, and cool naturally to room temperature to obtain the mass fraction of EPDM rubber It is 7% spinning dope.

[0073] Spinning: Inhale the spinning stock s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com