Automatic processing equipment for insulated strain-resistant wire clamp

An insulation tension clamp and automatic processing technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of the failure of the insulation tension clamp, difficult clamping and positioning, low labor efficiency of threaded holes, etc. The effect of good product molding quality and high labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

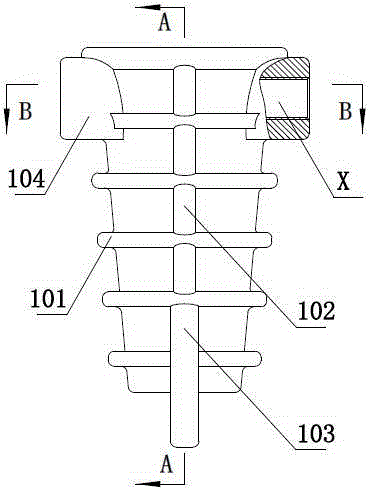

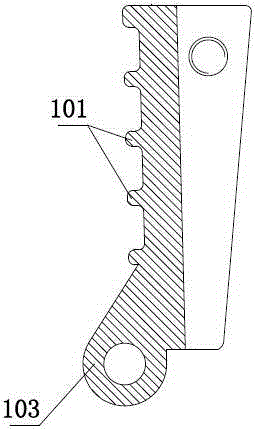

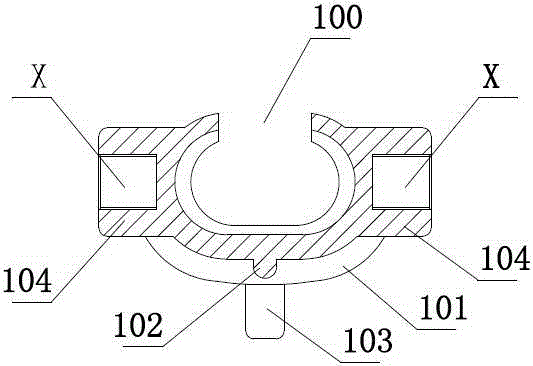

[0027] Such as figure 1 , figure 2 with image 3 As shown, the main body of the insulating strain clamp in the prior art is molded by casting aluminum material. After casting, the insulating strain clamp is as follows: figure 1 The shape shown is roughly wedge-shaped. For the convenience of description, the figure 1 The up and down distance in is its height, and the figure 2 The left and right distance in is its thickness, with image 3 The upper and lower distances are its width, and the section of the insulation strain clamp is as follows: image 3 As shown, it is roughly C-shaped, that is to say, the insulating tension clamp has an inner cavity with an opening 100 on one side, and the opening 100 penetrates from the upper part to the lower part, and the outer surface of the insulating tension clamp has multiple transverse ribs 101 and a vertical rib 102, and its bottom is provided with outwardly protruding lugs 103, and both sides of the upper part of the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com