Novel egg roll forming and clamping device

A new type of egg roll technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increased probability of machine injury, frequent contact between personnel and equipment, broken egg rolls, etc. Stable and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

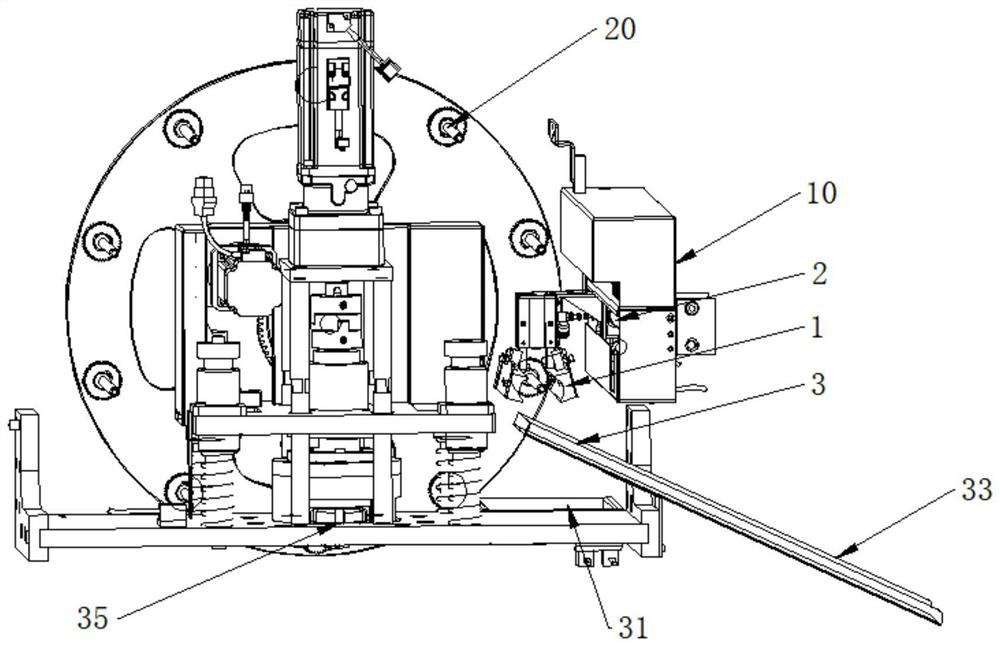

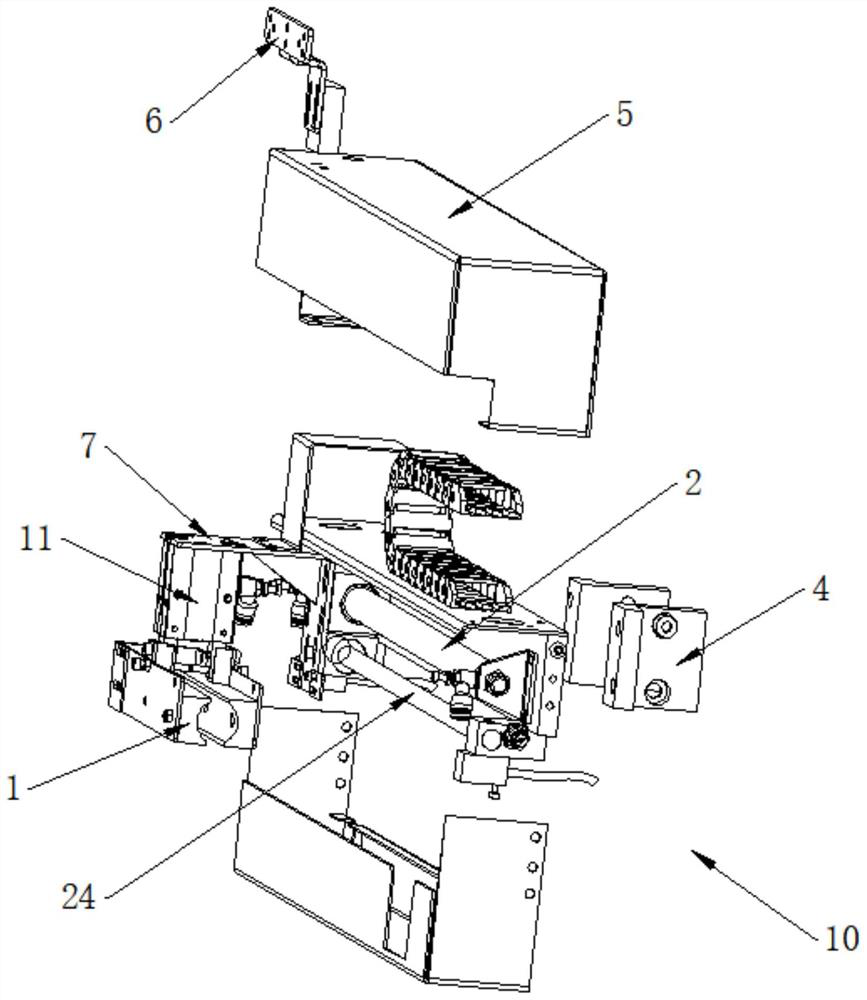

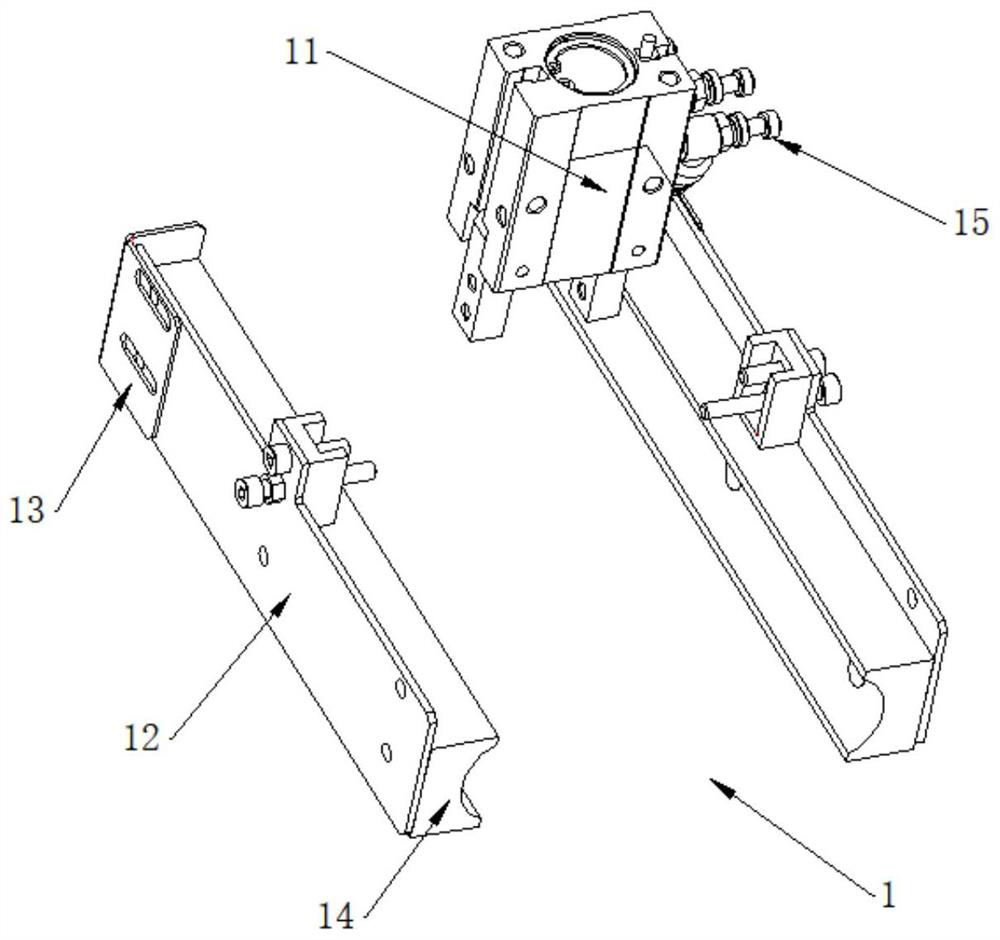

[0048] A novel egg roll forming and clamping device, comprising a clamping device body 10, the clamping device body 10 is arranged on one side of a roll assembly 20, and the clamping device body 10 comprises a clamping assembly 1, a cylinder assembly 2 and the material receiving assembly 3, the clamping assembly 1 is connected with the cylinder assembly 2, and the material receiving assembly 3 is arranged below the clamping assembly 1; Sheet 13 and material clip 14, the air claw 11 is connected with the cylinder assembly 2, the material clamping plate 12 is connected below the air claw 11, the material clamping plate 12 is fixed on the inner side of the material clamping plate 14, and the material clamping plate 12 is close to the roller One end of the assembly 20 is connected with a scraping blade 13 , the material clip 14 is provided with an arc-shaped clamping part adapted to the formed egg roll, and the scraping blade 13 is provided with a roller adapted to the rolling roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com