Welding process for wall bars of steel bar cage

A welding process and technology of steel cages, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems such as unfavorable long-term use of steel cages, affecting structural durability, affecting performance of steel cages, etc., to overcome the operating space and operating angle. Harsh conditions, ensure quality and construction quality, and ensure the effect of pile foundation concrete quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of side bar welding process that is used for reinforcement cage, concrete steps are as follows:

[0039] (1) Selection of welding consumables: selection of welding consumables, the standards of welding consumables should comply with GB / T5117 of "Carbon Steel Welding Rods" or GB / T5118 of "Low Carbon Steel Welding Rods"; Dry in an oven to make it meet the requirements; the welding consumables that meet the requirements should be placed on the rootstock when stored, and 150mm away from the ground; carry out on-site sampling re-inspection and list for use;

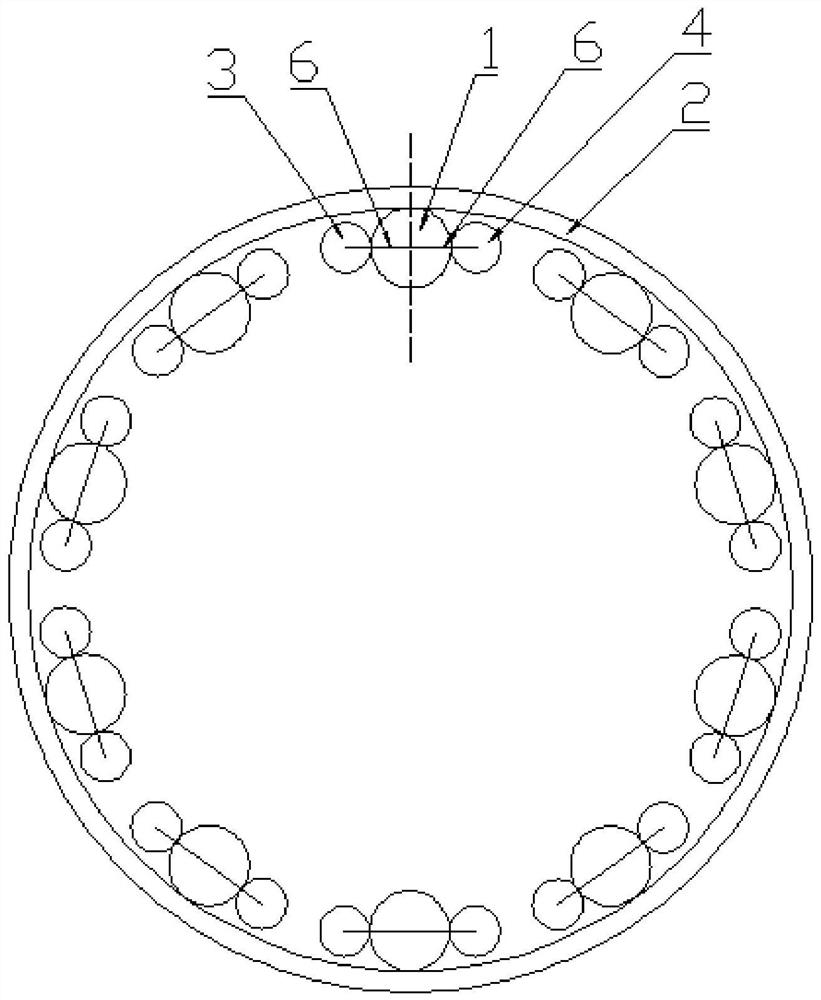

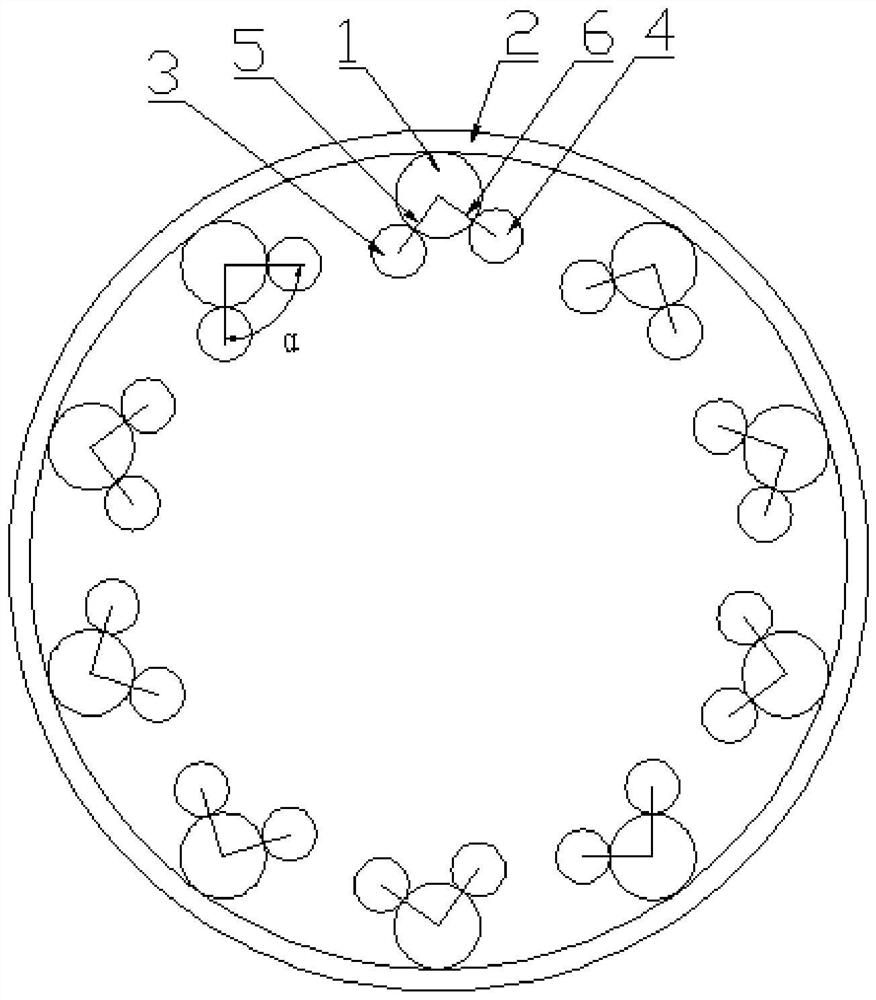

[0040] Welded reinforcement cage: the diameter of the main reinforcement 1 of the reinforcement cage is 32mm, the diameter of the stirrup 2 is 12mm, the design length of the main reinforcement 1 and the stirrup 2 is 26 meters, a total of 18, and the stirrup is a spiral structure. The main reinforcement is penetrated into the type and fastened with binding wires to form a cylindrical steel cage skeleton;

[0041]...

Embodiment 2

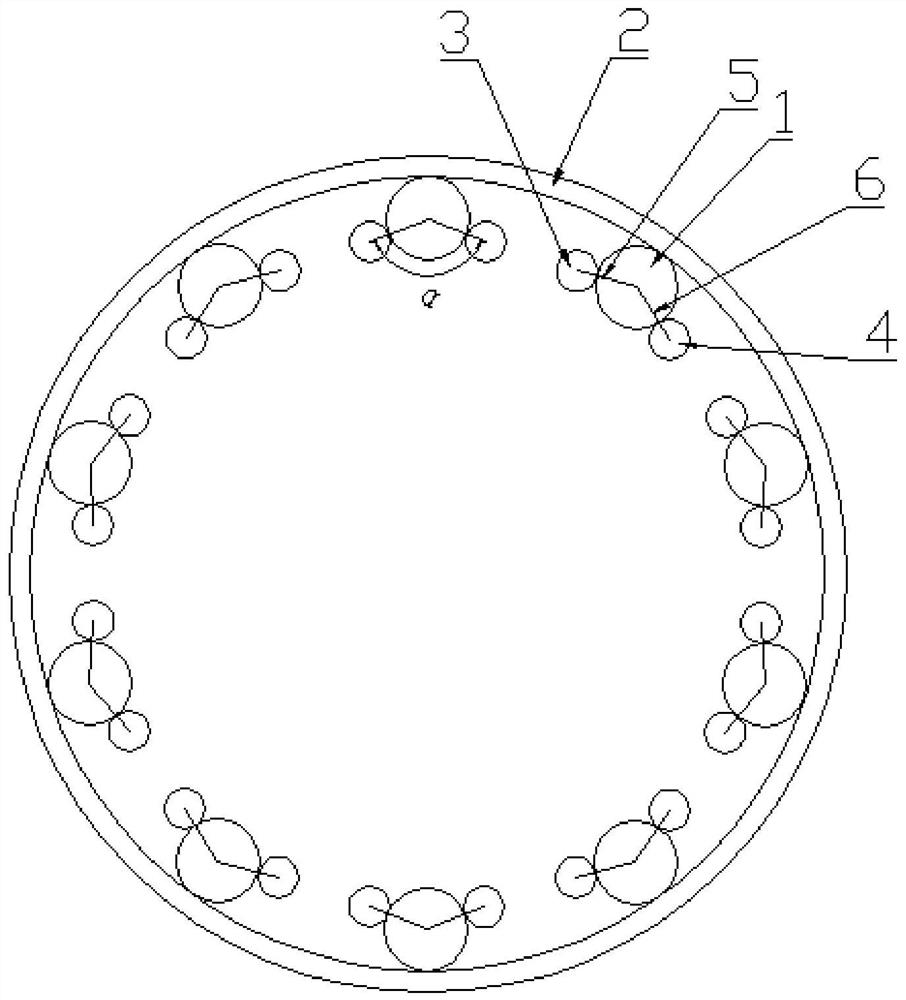

[0048] The difference from Example 1 is that the included angle α is 135°, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com