Welding-free unequal-thickness wheel type engineering machinery wheel and manufacturing technology for same

A construction machinery, non-welding technology, applied in the direction of web-type wheels, wheels, vehicle parts, etc., can solve the problems of being unable to withstand cyclic impact stress, etc., and achieve the effects of reducing traffic safety hazards, increasing strength, and streamlining management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

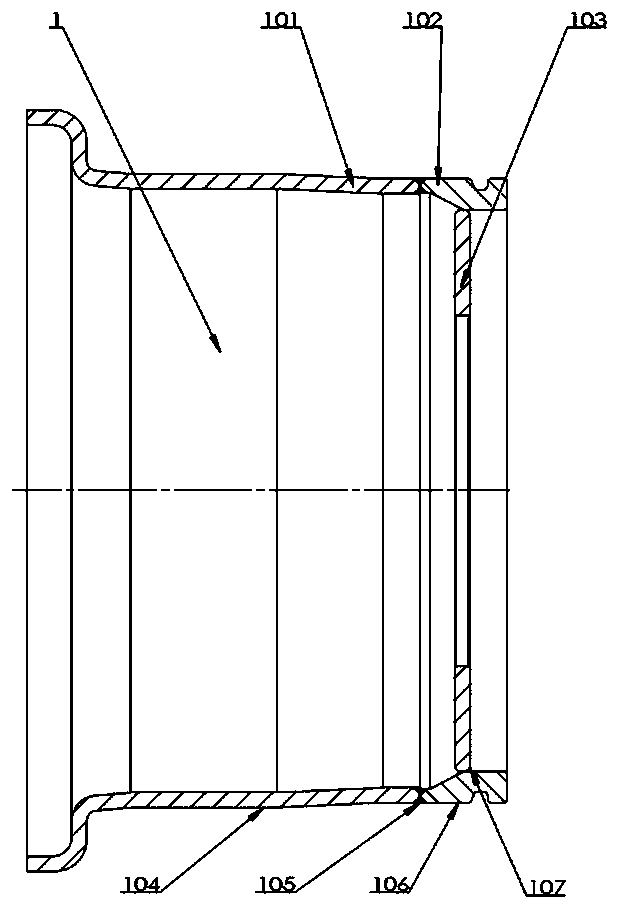

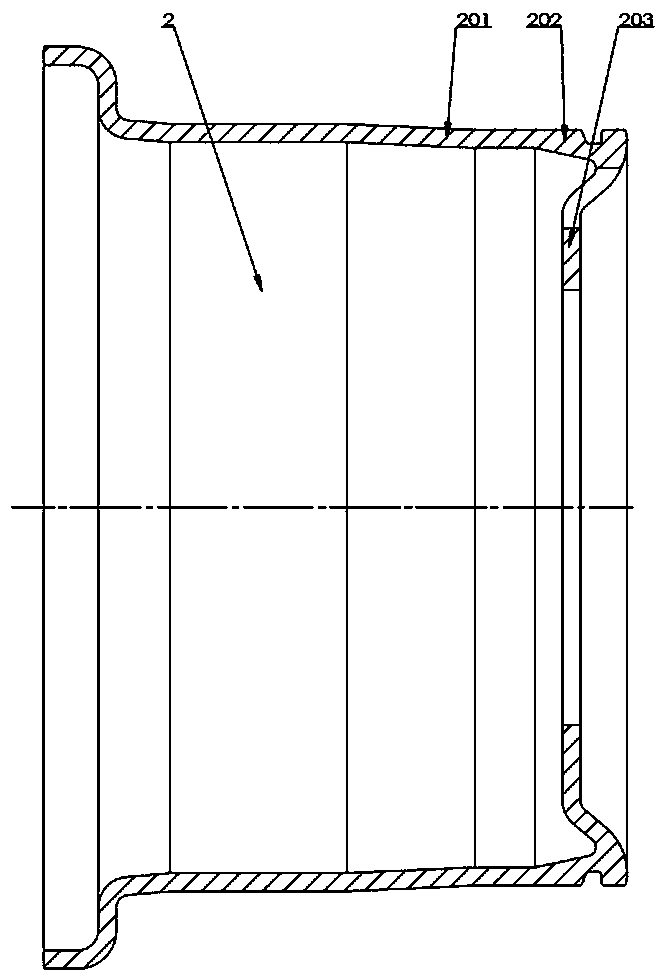

[0025] Such as figure 2 As shown, the non-welding wheel type construction machinery wheel of unequal thickness, including the wheel body 2, can also be divided into three parts according to the different structural functions of the wheel body 2: the non-welding rim cylinder 201, the non-welding bead seat 202, the non-welding Weld the spokes 203.

[0026] The non-welded rim cylinder 201 is formed into unequal thickness by spinning. According to the different product contours, the maximum thickness can reach 20mm, and the minimum thickness is 5mm. Combined with mechanical analysis and practical application, the variable section of the wheel product can be optimized. To achieve maximum weight reduction, the retaining ring groove of the bead seat is formed by spinning in the later stage.

[0027] The connection between the non-welding bead seat 202 and the non-welding spoke 203 adopts the forging process to form the concave contour of the curved surface, which realizes the conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com