Surface treatment method for improving welding properties of Si3N4 ceramic and gamma-TiAl alloy

A technology for surface treatment and welding performance, which is applied in the field of surface treatment to improve the welding performance of Si3N4 ceramics and γ-TiAl alloys. The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: prepare the material used for welding, process according to the following steps:

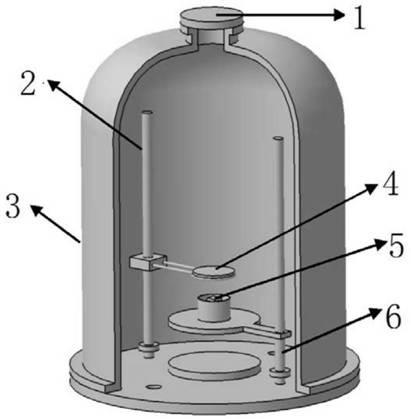

[0047] (1) Put the γ-TiAl alloy and the Ni target into the double-glow plasma surface alloying device, use the γ-TiAl alloy as the workpiece electrode, and use the pure Ni target material (99.95wt%) as the source electrode;

[0048] (2) Vacuumize to the ultimate vacuum, send in argon, start the glow, first clean the target and γ-TiAl alloy, and prepare the nickel alloy layer after cleaning, the steps are as follows:

[0049] (2a) Low-temperature bombardment of the target (plasma cleaning) for 30 minutes to remove scale and impurities on the surface of the target. The process parameters are as follows:

[0050] Target voltage: 650V;

[0051] Workpiece voltage: 0V;

[0052] Argon pressure: 20Pa;

[0053] Distance between target and workpiece: 20mm;

[0054] Cleaning time: 30min;

[0055] (2b) Adjust the voltage of the target to zero, and continue bombarding the γ-TiAl all...

Embodiment 2

[0071] Embodiment 2: prepare the material used for welding, process according to the following steps:

[0072] (1) Put the γ-TiAl alloy and the Ni target into the double-glow plasma surface alloying device, use the γ-TiAl alloy as the workpiece electrode, and use the pure Ni target material (99.95wt%) as the source electrode;

[0073] (2) Vacuumize to the ultimate vacuum, send in argon, start the glow, first clean the target and γ-TiAl alloy, and prepare the nickel alloy layer after cleaning, the steps are as follows:

[0074] (2a) Low-temperature bombardment of the target (plasma cleaning) for 30 minutes to remove scale and impurities on the surface of the target. The process parameters are as follows:

[0075] Target voltage: 750V;

[0076] Workpiece voltage: 0V;

[0077] Argon pressure: 25Pa;

[0078] Distance between target and workpiece: 15mm;

[0079] Cleaning time: 30min;

[0080] (2b) Adjust the voltage of the target to zero, and continue bombarding the γ-TiAl all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com