Ultralight lithium ion battery current collector and preparation method thereof

A technology of lithium-ion batteries and current collectors, which is applied in the directions of battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as difficult industrial application and difficulties, and achieve energy density improvement, weight reduction and space occupation, and improvement The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

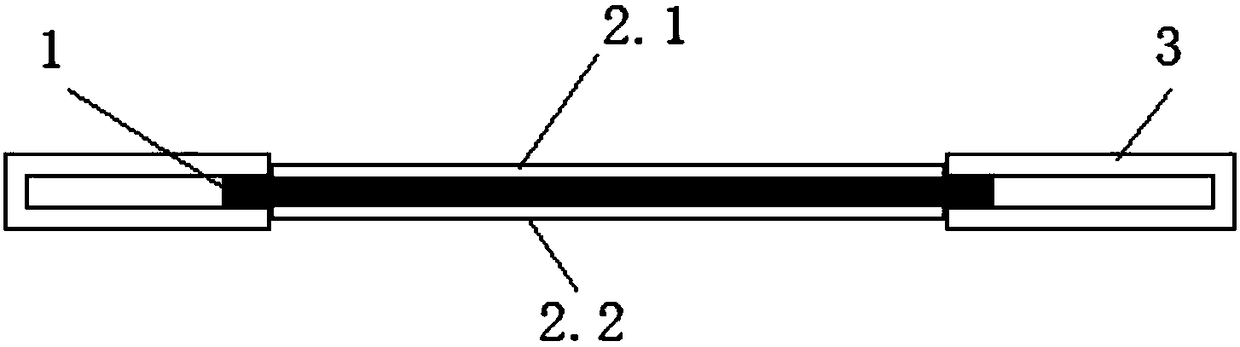

[0026] Embodiment 1: as figure 1 As shown, a current collector for an ultra-light lithium ion battery includes a PET layer 1, U-shaped metal sheets 3 are clamped at both ends of the PET layer 1, and the PET layer 1 between the metal sheets 3 at both ends The upper metal layer 2.1 and the lower metal layer 2.2 are plated on the sides of both sides.

[0027] In a further solution, the thickness of the PET layer 1 is 4-10 μm.

[0028] In a further solution, the metal layer and the metal sheet 3 are made of the same material, which are copper, aluminum or nickel.

[0029] In a further solution, the thickness of the upper metal layer 2.1 or the lower metal layer 2.2 is 0.5-2 μm.

[0030] In a further solution, the thickness of the metal flake is 4.5-15 μm.

[0031] In a further solution, the metal sheet 3 is 0.5-4 cm beyond the end of the PET layer 1 .

Embodiment 2

[0033] A preparation method for an ultra-light lithium ion battery current collector, comprising the following steps:

[0034] (1) Coating a layer of adhesive layer on both sides of the end of the PET layer;

[0035] (2) Fold the metal sheet in half into a U-shaped structure, bond the two ends of the metal sheet to the adhesive layers on both sides of the PET layer, and combine the PET layer and the metal sheet by thermal compounding;

[0036] (3) Coating a metal layer on both sides of the PET layer located between the metal sheets at both ends.

[0037] When plating the metal layer, the metal layer will also be plated at the connection between the metal sheet and the PET layer, so that there is an overlapping area between the metal layer and the metal sheet, and the width of the overlapping area is 0.5~2cm.

[0038] In a further scheme, the binder is polyvinylidene fluoride-co-hexafluoropropylene, polyvinylidene fluoride-co-trifluoroethylene, polymethyl methacrylate, polybut...

Embodiment 3

[0041] A preparation method for an ultra-light lithium ion battery current collector, comprising the following steps:

[0042] (1) Coating a layer of cyanoethyl pullulan on both sides of the end of the PET layer;

[0043] (2) Fold the copper sheet into a U-shaped structure, bond the two ends of the copper sheet to the cyanoethyl branched chain lake on both sides of the PET layer, and use thermal compounding to composite the PET layer and the copper sheet together ;

[0044] (3) Using a high-power electron beam process, a copper layer is vacuum evaporated on both sides of the PET layer located between the copper sheets at both ends.

[0045] When the copper layer is plated, a copper layer is also plated at the connection between the copper sheet and the PET layer, so that there is an overlapping area between the copper layer and the copper sheet, and the width of the overlapping area is 0.5~2cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com