Distributing device for electronic components and control method of distributing device

A technology for electronic components and device control, which is applied to conveyor objects, transportation and packaging, metal processing, etc. It can solve the problems of inconvenient storage and welding, low efficiency of manual cutting, and limitation of shearing process, etc., and achieves convenient material replacement , facilitate material management and distribution, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

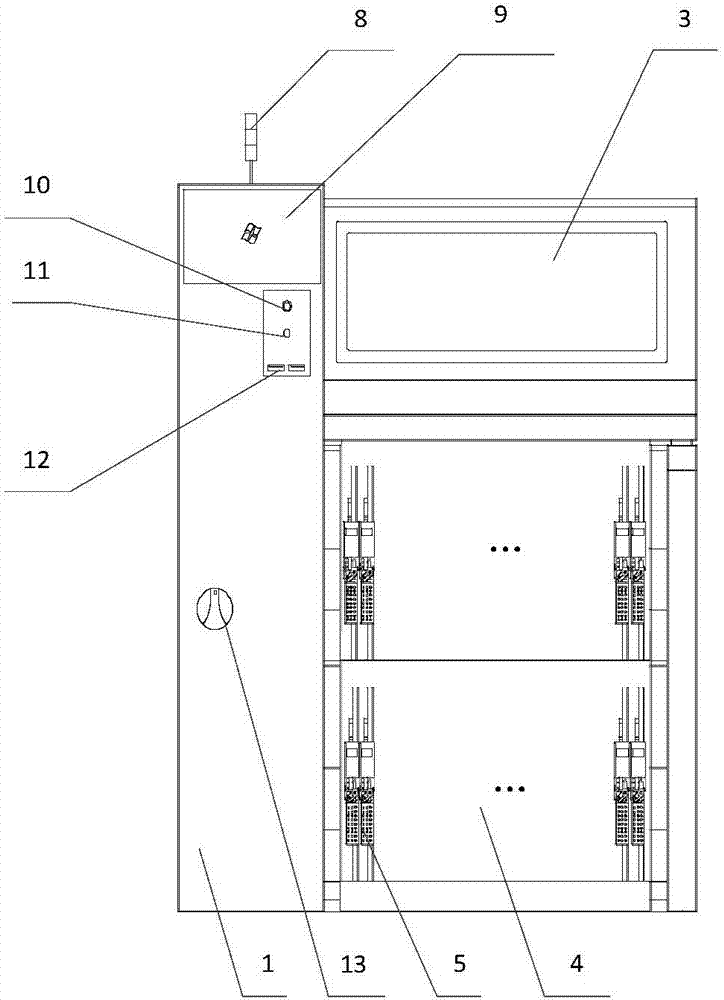

[0047] The present invention is mainly applied to electronic component material batching, such as Figure 1 to Figure 8 As shown, the device includes an equipment cabinet 1, a material gun frame 2 arranged in parallel on the right side of the equipment cabinet 1, an electrical equipment compartment 3 pressed on the top of the material gun frame 2 and whose left edge is fixed on the side edge of the equipment cabinet 1, embedded in the The touch screen 9 on the upper edge of the front part of the equipment cabinet 1 is installed on the top of the equipment cabinet 1 and is used to indicate the three-color indicator light 8 of the working state, and is embedded in the gun frame 2 and is equipped with two rows of evenly distributed guns 5 . Wherein, two rows of square holes 4 for embedding firing guns 5 are provided at the front of the gun rack 2 .

[0048] The firing gun 5 of this device comprises the middle section plate 25 that is embedded in the square hole 4, is buckled on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com