Technique for processing joint where box steel beams with relatively large slenderness ratios of sections are in butt joint

A box-shaped steel girder and processing technology, applied in the processing of building materials, bridges, bridge construction, etc., can solve problems such as unfavorable engineering construction quality control, difficulty in welding lower flange plates, loss of web section, etc., to achieve Convenient construction, convenient welding, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

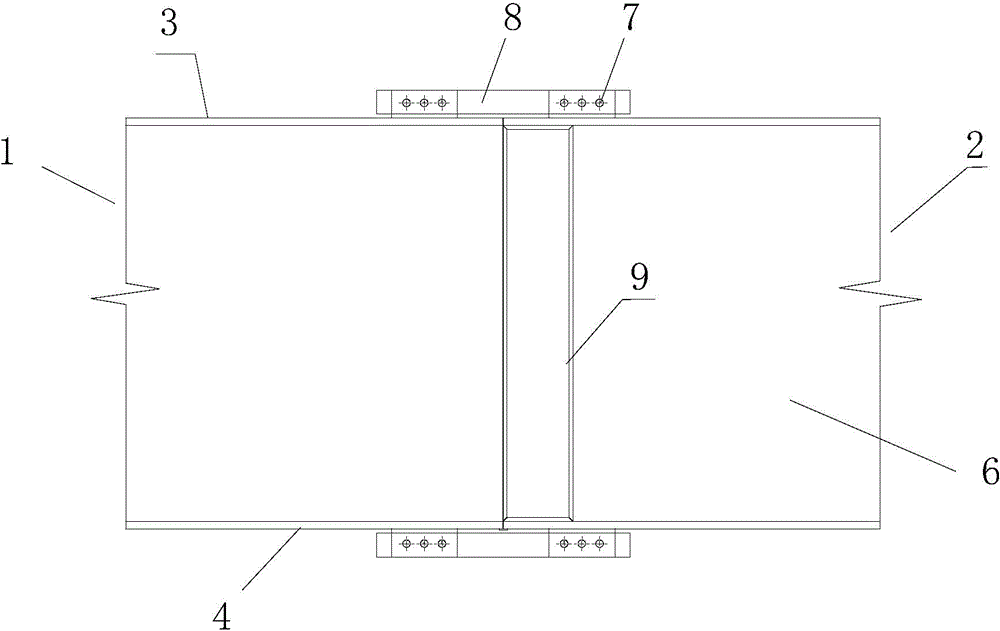

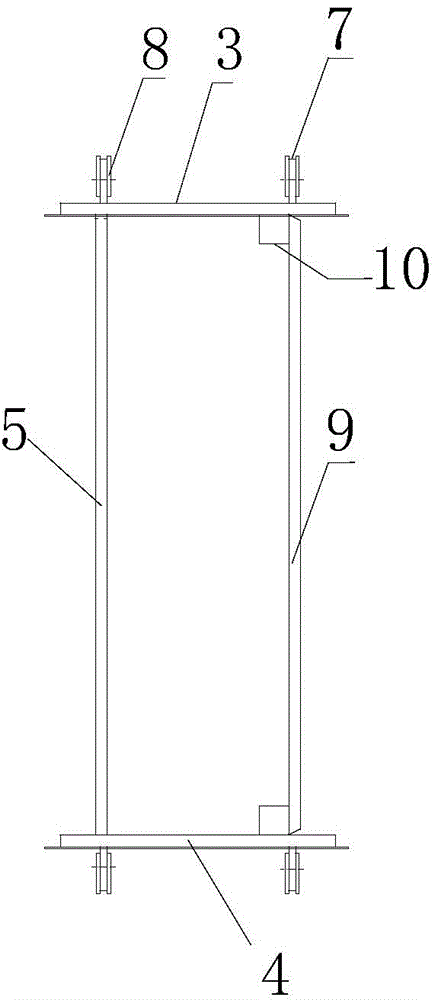

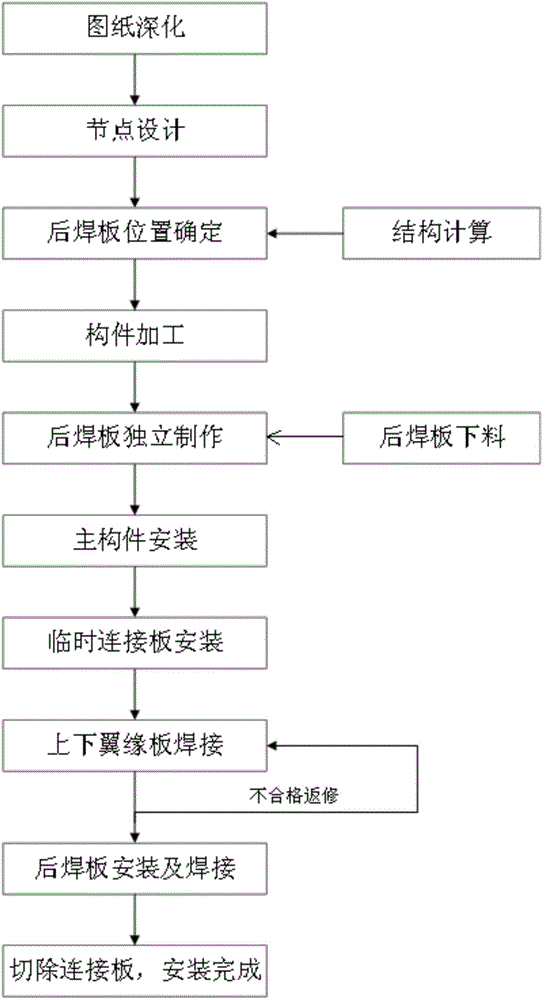

[0014] see figure 1 , figure 2 and image 3 , the treatment process of the butt joint joints of box-shaped steel beams with relatively large slenderness ratio, the first box-shaped steel beam 1 and the second box-shaped steel beam 2 are composed of upper flange plate 3, lower flange plate 4 and the The first web 5 and the second web 6 on both sides are composed, and the rear welding plate 9 is reserved on one of the first web 5 and the second web 6. During installation, the first box steel girder 1 and each of the upper flange plate 3 and the lower flange plate 4 of the second box-shaped steel girder 2 are provided with double connecting lugs 7, and the connecting plates 8 are used to connect the double connecting lugs 7 to connect the first box-shaped steel girder 1 It is butted together with the second box-shaped steel girder 2. After the first box-shaped steel girder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com