Three-stage filter

A filter, three-stage technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of high filter processing and assembly costs, inconvenient replacement, etc., to avoid separate installation and welding, simplify quantity, and improve delivery efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

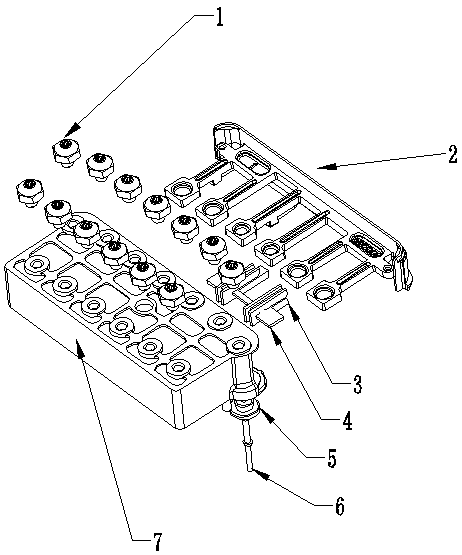

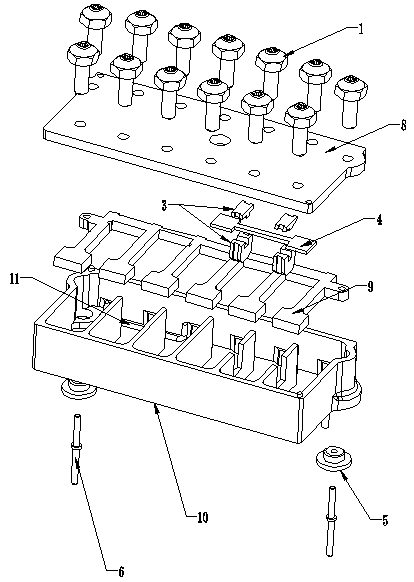

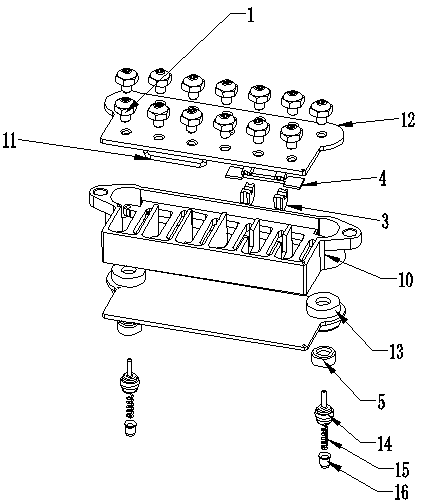

[0026] As shown in the figure, the specific implementation method is as follows:

[0027] A three-section filter, comprising a cavity 10, the cavity 10 is divided into six resonant cavities by partitions, each resonant cavity is provided with a resonant plate, and the resonant plates in two adjacent resonant cavities are connected to each other , wherein the flying rod seat 3 is installed on the two partitions, the flying rod sheet 4 is installed on the flying rod seat 3, the flying rod line 11 is installed on the two resonant sheets, and the cavity 10 is open at both the upper end and the lower end The structural parts, the partition and the resonator are all implanted on the side wall of the cavity 10, the partition and the resonator are all integrated with the cavity 10, the upper end cover of the cavity 10 is provided with an upper cover plate 12, and the lower end of the cavity 10 The cover is provided with a lower cover plate 13, and the upper cover plate 12 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com