Method for welding metal under strong magnetic field circumstance

A welding method and strong magnetic field technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that metal parts cannot meet the strength requirements, slag inclusions, pores, cracks, and welding quality are easy to appear, and achieve welding Good meat fusion, reduced welding defects, and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

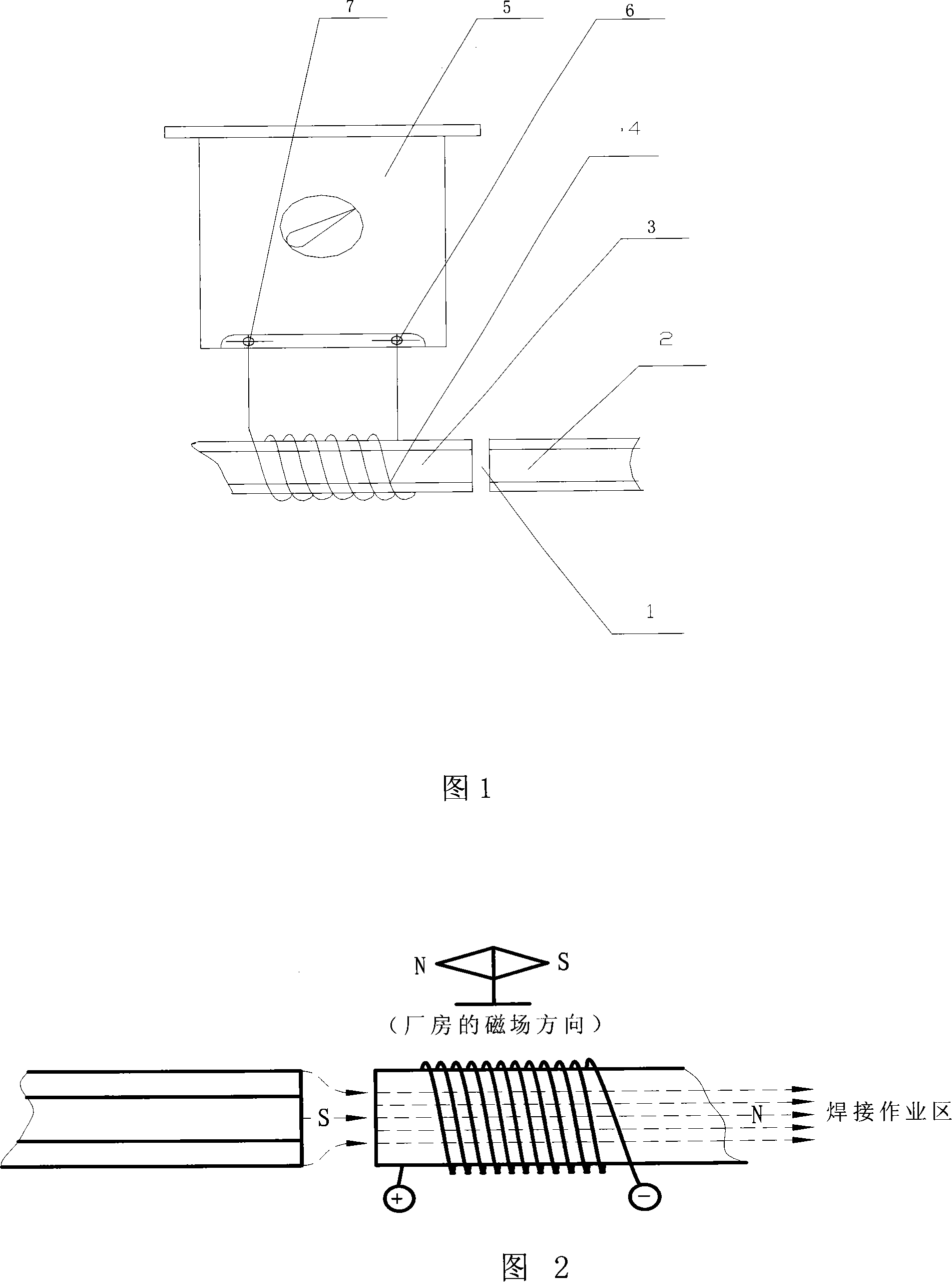

[0015] As shown in Figure 1, wrap the wire 4 of appropriate length on the metal workpiece 2 or metal workpiece 3 to be welded on any side of the metal workpiece welding point 1 with a certain number of turns and direction, and the two ends of the wire 4 are respectively connected to the DC welding machine. The positive terminal 6 and the negative terminal 7 of the DC welding machine are connected together, thus forming a current loop. When the switch of the DC welding machine 5 is turned on, a magnetic field superimposed with a strong magnetic field is generated in the welding area. The field strength at the welding point 1 of the metal workpiece. If the direction of the magnetic field remains unchanged and the strength increases, it indicates that the winding direction of the wire 4 is wrong. Wind the wire 4 in the opposite direction, and then adjust the number of turns of the wire 4 so that the measured field strength is zero; if the field strength decreases or the direction ...

Embodiment 2

[0017] Wrap the wire 4 of appropriate length on the metal workpiece 2 or metal workpiece 3 to be welded on any side of the metal workpiece welding point 1 with a certain number of turns and directions, and the two ends of the wire 4 are respectively connected to the positive terminal 6 of the DC welding machine and the DC welding machine. The negative terminal 7 of the machine wiring is connected, so that a current loop is formed, and the switch of the DC welding machine 5 is turned on, and a magnetic field superimposed with a strong magnetic field is generated in the welding area, and a small steel plate is placed on the side of the metal workpiece 2 or metal workpiece 3 , if the mutual magnetic force between the small steel plate and the metal workpiece 2 or metal workpiece 3 disappears, and the small steel plate does not adhere to the metal workpiece 2 or metal workpiece 3, then the winding direction and the number of turns of the electric wire 4 are appropriate; if the small...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com