Method for mounting support column of slag notch of incinerator

An installation method and slag tap technology are applied in the field of installation of support columns of incinerator slag taps, which can solve problems such as uniform deformation, difficult connection, and inability to adjust, achieve uniform impact and vibration force, solve welding difficulties, and shorten installation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments.

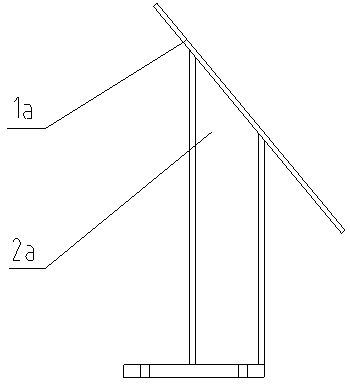

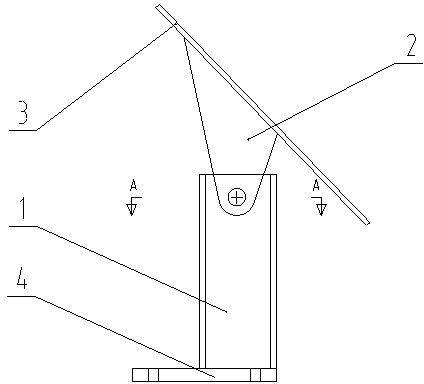

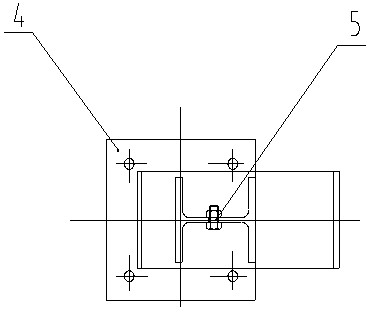

[0021] see Figure 2~Figure 3 : The installation method of the support column of the slag discharge tank of the incinerator, the method adopts a steel structure column with adjustable connectors, the column includes a column body 1 and a column connector 2, the column body 1 is H-shaped steel, and the column connector 2 is The upper part of the column body 1 is provided with a hole a, the lower part of the column connector 2 is provided with a hole b, and the column body 1 and the column connector 2 are connected by bolts 5 . In order to improve the force bearing structure, the hole a is set at the middle position of the upper part of the column body 1 , and the hole b is set at the middle position of the lower part of the column connecting head 2 .

[0022] In order to facilitate welding after fitting with the inclined support plate 3, the support surface of the column co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com