Surface treatment method for improving welding properties of Al2O3 ceramic and Ti6Al4V alloy

A surface treatment and welding performance technology, which is applied in the field of surface treatment to improve the welding performance of Al2O3 ceramics and Ti6Al4V alloys, can solve the problems of welding difficulties between ceramics and Ti6Al4V alloys, and achieve the effects of improving fracture toughness, high efficiency, and increasing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

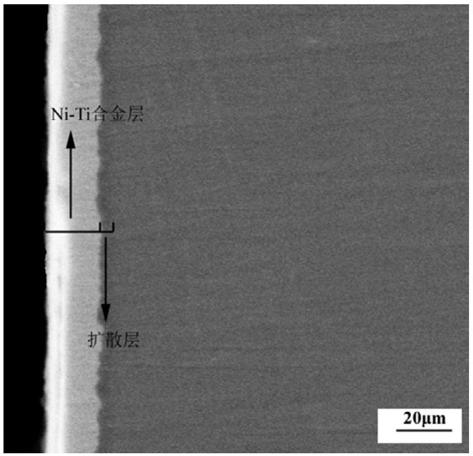

[0046] Embodiment 1: prepare the material used for welding, process according to the following steps:

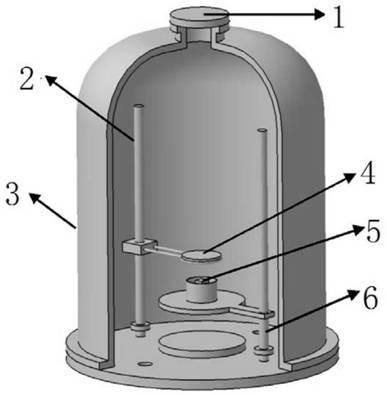

[0047] (1) Put the Ti6Al4V alloy and Ni-Ti alloy target into the double-glow plasma surface alloying device, use the Ti6Al4V alloy as the workpiece pole, and use the Ni-Ti alloy target (Ni accounts for 70wt%, Ti accounts for 30wt%) as the source pole;

[0048] (2) Vacuumize to the ultimate vacuum, send in argon, start the glow, first clean the target and Ti6Al4V alloy, and prepare the Ni-Ti alloy layer after cleaning. The steps are as follows:

[0049] (2a) Low-temperature bombardment of the target (plasma cleaning) for 30 minutes to remove scale and impurities on the surface of the target. The process parameters are as follows:

[0050] Target voltage: 650V;

[0051] Workpiece voltage: 0V;

[0052] Argon pressure: 20Pa;

[0053] Distance between target and workpiece: 20mm;

[0054] Cleaning time: 30min;

[0055] (2b) Adjust the voltage of the target to zero, and conti...

Embodiment 2

[0071] Embodiment 2: prepare the material used for welding, process according to the following steps:

[0072] (1) Put the Ti6Al4V alloy and Ni-Ti alloy target into the double-glow plasma surface alloying device, use the Ti6Al4V alloy as the workpiece pole, and use the Ni-Ti alloy target (Ni accounts for 70wt%, Ti accounts for 30wt%) as the source pole;

[0073] (2) Vacuumize to the ultimate vacuum, send in argon, start the glow, first clean the target and Ti6Al4V alloy, and prepare the Ni-Ti alloy layer after cleaning. The steps are as follows:

[0074] (2a) Low-temperature bombardment of the target (plasma cleaning) for 30 minutes to remove scale and impurities on the surface of the target. The process parameters are as follows:

[0075] Target voltage: 750V;

[0076] Workpiece voltage: 0V;

[0077] Argon pressure: 25Pa;

[0078] Distance between target and workpiece: 15mm;

[0079] Cleaning time: 30min;

[0080] (2b) Adjust the voltage of the target to zero, and conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com