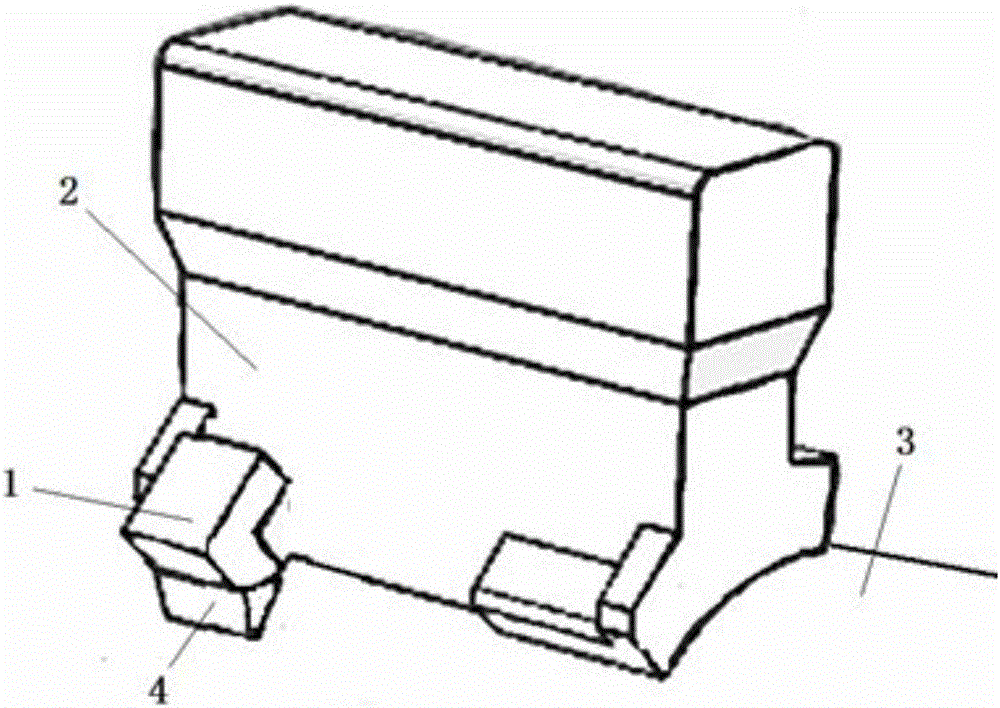

Method for installing Co40 cushion block on water beam in walking beam type heating furnace

A walking heating furnace and installation method technology, which is applied in the field of metallurgy, can solve the problems of water beam wrapping damage, steel billet tilting and scratching the furnace wall, bursting tubes, etc., and achieve the effect of improving bending resistance and ensuring installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

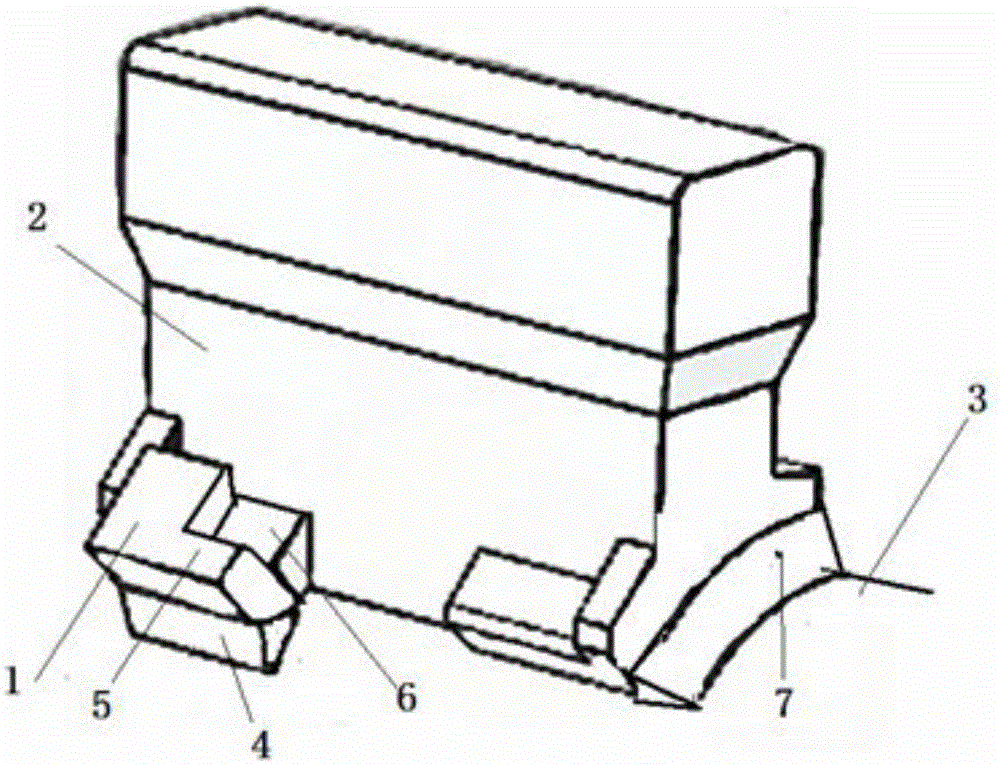

[0010] Such as figure 2 As shown, an extension 5 is added to the side of the block 1, and there is a first welding part 6 between the extension 5 and the Co40 block 2; the Co40 block 2 and the block 1 are fixed by the first welding part 6 Connection; the block 1 and the water beam 3 are connected by the second welding part 4; the first welding part 6 and the second welding part 4 can form an integral welding part; the two ends of the Co40 pad 1 and the water beam 3 pass The third welding part 7 is welded into one body;

[0011] Both ends of the Co40 pad are welded with cobalt-based surfacing electrodes, and the electrodes are baked at a temperature of 200℃~300℃ for 1-2 hours before welding; angle grinding wheels are used to remove the roots and rust to see the metallic luster at the weld, and use a DC welding machine Reverse connection (the base material is connected to the positive electrode), using 60-120 (A) current, narrow welding bead, fast welding, preferably without late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com