Welding method of titanium welded tube for petrochemical engineering

A welding method and technology of titanium welded pipes, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve problems such as long manufacturing cycle, titanium rebound, and difficulty in pipe penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

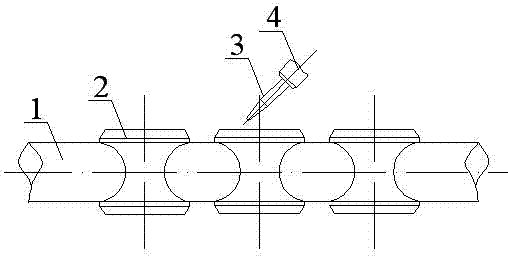

Embodiment 1

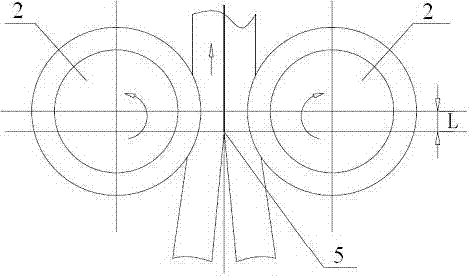

[0024] The raw material is TA2 titanium strip, the width is 60.0~60.5, and the wall thickness is 1.25mm. It is continuously cold-formed by using a Φ19-sized roll mold to prepare a Φ19×1.25mm-sized straight seam titanium welded pipe. The narrow titanium strip is formed by continuous cold bending, tungsten argon arc welding, welding process parameters: welding speed 0.5~1m / min, welding current 110~125A, welding voltage 8.8~98V, argon gas flow 10~25l / min, welding The opening of the squeeze roller is 1.7mm, and the inclination angle between the welding torch and the workpiece is 30°, so that the weld seam is fully filled and the transition is smooth. After welding, the eddy current non-destructive flaw detection device is used to monitor the quality of the weld, alarm if there is a defect, and cut off the alarm part. After welding, the pipe is subjected to sizing straightening and on-line induction annealing heat treatment. Online induction annealing to remove the stress remainin...

Embodiment 2

[0027] The raw material is TA2 titanium strip, the width is 79.3~79.6, and the wall thickness is 1.25mm. It is continuously cold-formed by using a Φ25-sized roll mold to prepare a Φ25×1.25mm-sized straight seam titanium welded pipe. The narrow titanium strip is formed by continuous cold bending and argon tungsten arc welding, using welding process parameters: welding speed 0.5~1m / min, welding current 120~135A, welding voltage 8.8~9.4V, argon flow 10~25 l / min , The opening of the welding squeeze roller is 2.0mm, and the inclination angle between the welding torch and the workpiece is 35°, so that the weld seam is fully filled and the transition is smooth. After welding, the eddy current non-destructive flaw detection device is used to monitor the quality of the weld, alarm if there is a defect, and cut off the alarm part. After welding, the pipe is subjected to sizing straightening and on-line induction annealing heat treatment. On-line induction annealing to remove the stress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com