Alternating-current electrochemical corrosion method of field emission electron source

A chemical corrosion, alternating current technology, applied in the field of electrochemical corrosion, can solve the problems of few adjustable parameters, very sensitive, difficult to control, etc., to achieve the effect of wide usable range, good stability and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

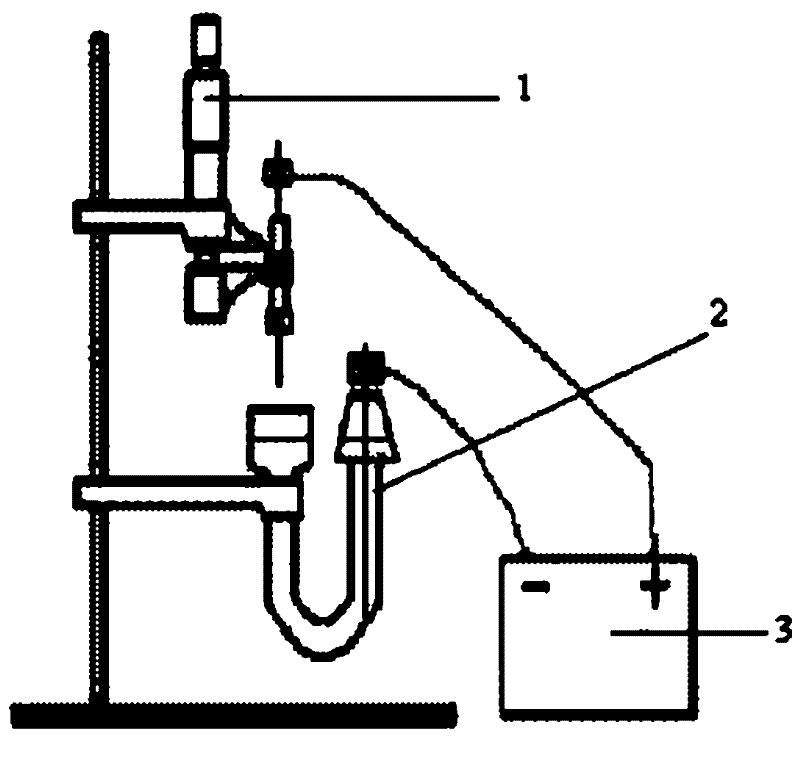

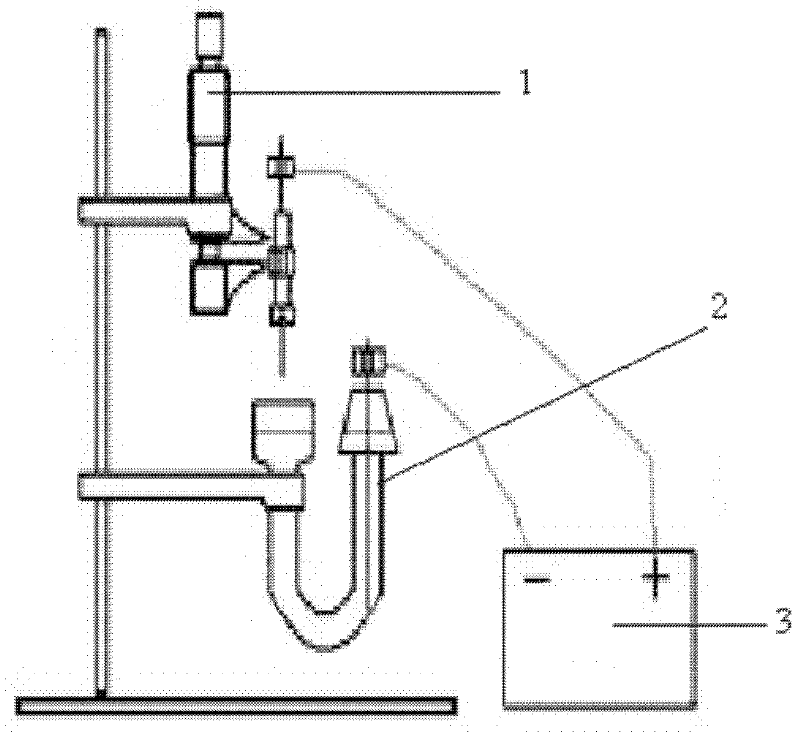

[0033] The device used in the alternating current electrochemical corrosion method of the present invention is as figure 1 As shown, it includes: fixed frame 1, which controls the depth of immersion of single crystal tungsten wire in the solution by adjusting the micrometer head installed on it; U-shaped tube 2, which is used as an electrolytic tank to hold corrosion solution; The power supply for chemical corrosion is directly connected to the two electrodes of the U-shaped tube 2 .

[0034] The steps of the AC electrochemical corrosion method of the single crystal tungsten wire of the field emission electron source of the present invention are as follows:

[0035] 1) Pour a certain amount of NaHO or KHO alkaline powder into a beaker with a balance, then measure a certain amount of pure water with a measuring cup, slowly pour the pure water into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com