Blended yarn spun by heat generating fiber, cotton and acrylic staple fiber and its production process

A technology of heating fiber and acrylic staple fiber, which is applied in the field of cotton spinning engineering to achieve a good effect of keeping warm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Siro spun smooth yarn - yarn for knitting, specification 32 s , JC / EKS ratio is 85% / 15%.

[0019] Raw material: EKS is 1.7dtex*38mm; JC grade is 2.2, and the main body length is 29mm.

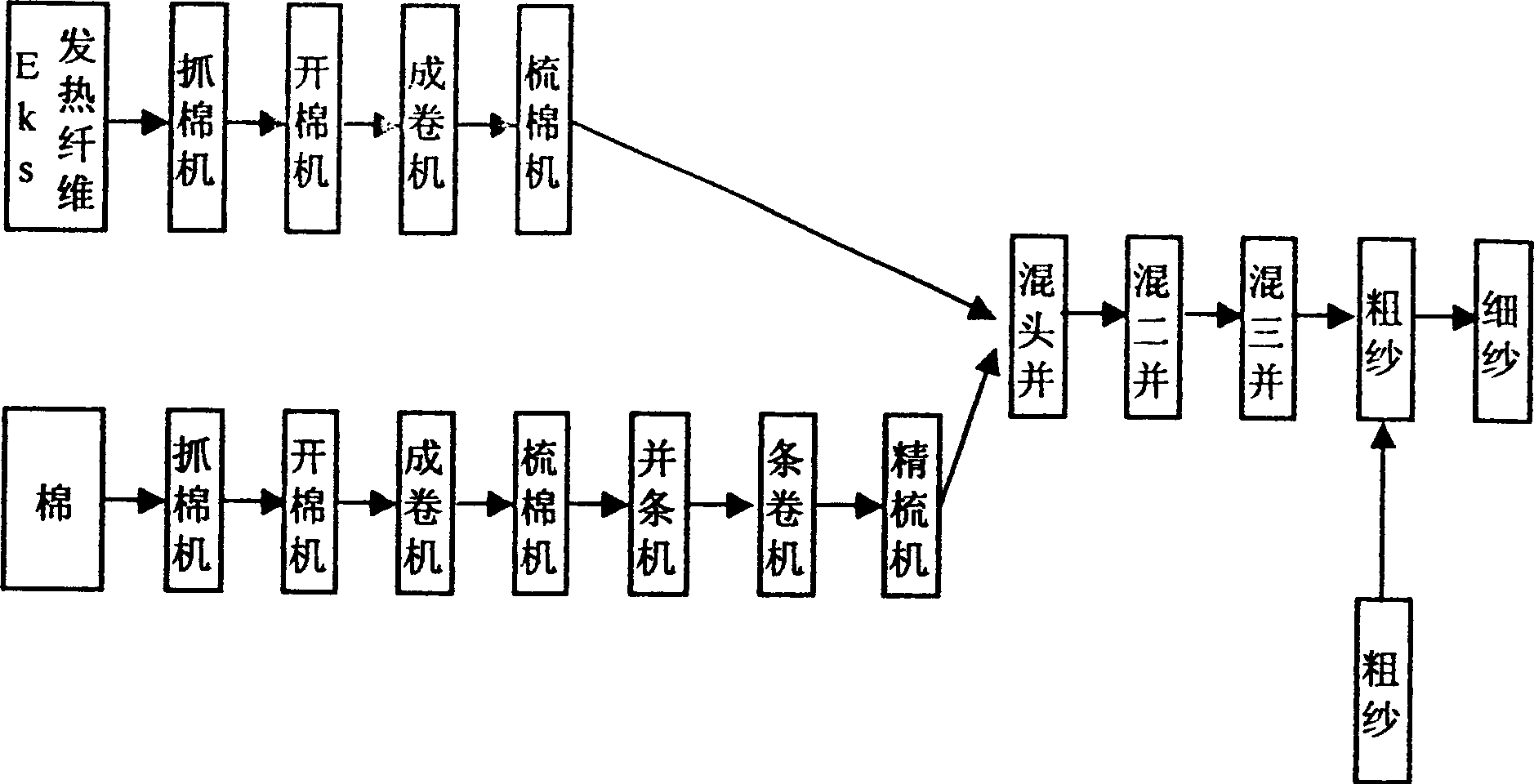

[0020] Process route: see attached figure 1 ,

[0021] EKS: Cotton bale-opener-coiler-carding machine

[0022] JC: Cotton plucking machine-opener-lapping machine-carding machine-drawing frame-sliver coiling machine-combing machine and then mix EKS raw sliver with JC combed sliver And - mix three and - roving, and then merge the same two groups of rovings - spun yarn.

[0023] Among them, the blending of EKS and combed cotton adopts the method of drawing and mixing. For EKS staple fiber, it is required that the blowing beater form of pre-spinning is best with comb needle, and the comprehensive beater of the lapping machine is changed to the comb beater, and the striking speed is reduced from about 900r / min to 650 / min. The state of the card clothing should be kept in good condition, ...

Embodiment 2

[0026] Heating fiber and cotton fiber blended knitting yarn, specification 42 s , JC / EKS is 60% / 40%.

[0027] Raw material: EKS is 1.7dtex*38mm; JC grade is 2.2, and the main body length is 29mm.

[0028] Process route: see attached figure 1 ,

[0029] EKS: Cotton bale-opener-coiler-carding machine

[0030] JC: Cotton plucking machine-opener-lapping machine-carding machine-drawing frame-sliver coiling machine-combing machine and then mix the EKS raw sliver and the combed sliver of JC. And - mix three and - roving, and then combine the same two groups of rovings - spun yarn.

[0031] Among them, the blending of EKS and combed cotton adopts the method of drawing and mixing. For EKS staple fiber, it is required that the blowing beater form of the pre-spinning is best with the comb needle, and the comprehensive beater of the lapping machine is changed to the comb beater, and the striking speed is reduced from about 900r / min to 710 / min. Card clothing should be kept in good co...

Embodiment 3

[0034] Heating fiber and acrylic fiber blended knitting yarn, the specification is 38 s , Anti-pilling acrylic fiber / EKS is 70% / 30%.

[0035] Raw materials: EKS: 1.7dtex*38mm; double-resistant acrylic: 0.9dtex*38mm

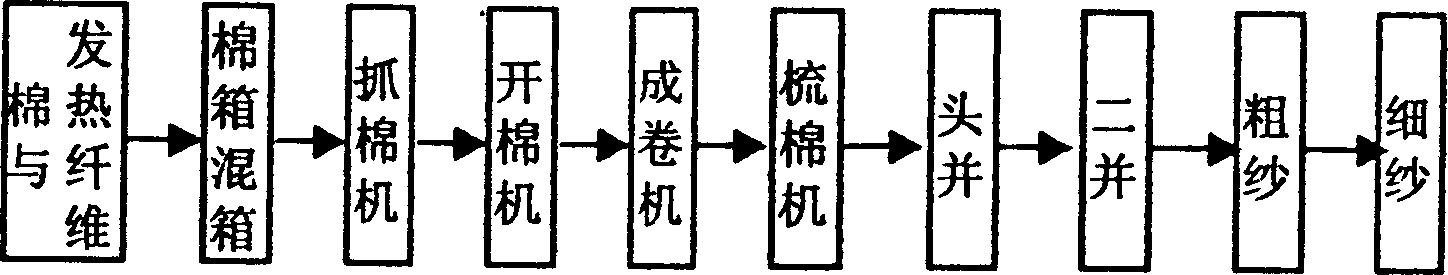

[0036] Process route: see attached figure 2 ,

[0037] EKS / Double-resistant acrylic fiber-Cotton box mixing box-Cotton plucking machine-Cotton opener-Coiler-Carding machine-Heading-two-dotting-roving-spinning.

[0038] Among them, the blending of EKS and acrylic fibers is in principle mixed with cotton boxes. Because the double-resistant acrylic fibers are fine-denier acrylic fibers, the focus of the work is to reduce the generation of short fibers and control the neps. For EKS staple fiber, it is required that the blowing beater form of the pre-spinning is best with the comb needle, and the comprehensive beater of the lapping machine is changed to the comb beater, and the striking speed is reduced from about 900r / min to 680min. The state of the card clothing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com