Pure- culture mixed fermented mildewed bean dregs and preparation method thereof

A technology of mixed fermentation and moldy bean dregs, applied in the directions of food preparation, application, food science, etc., to increase the amount of edible fiber, improve the nutritional value, and eliminate the harshness and beany smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

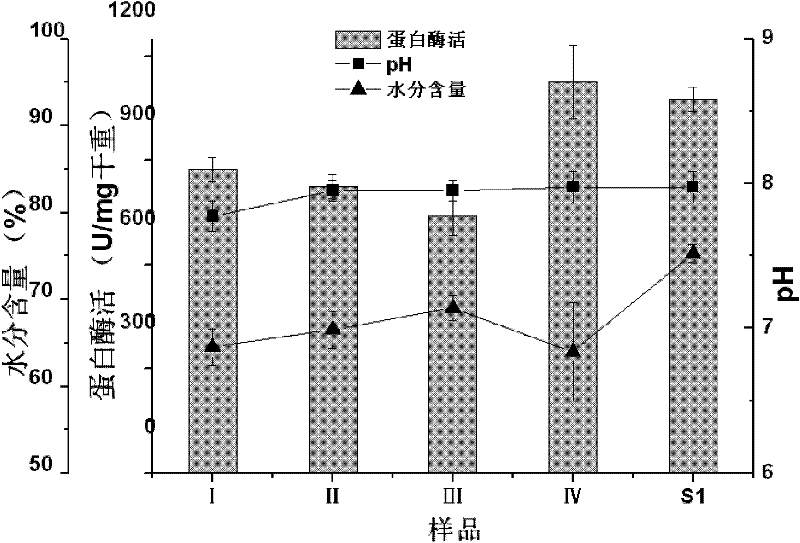

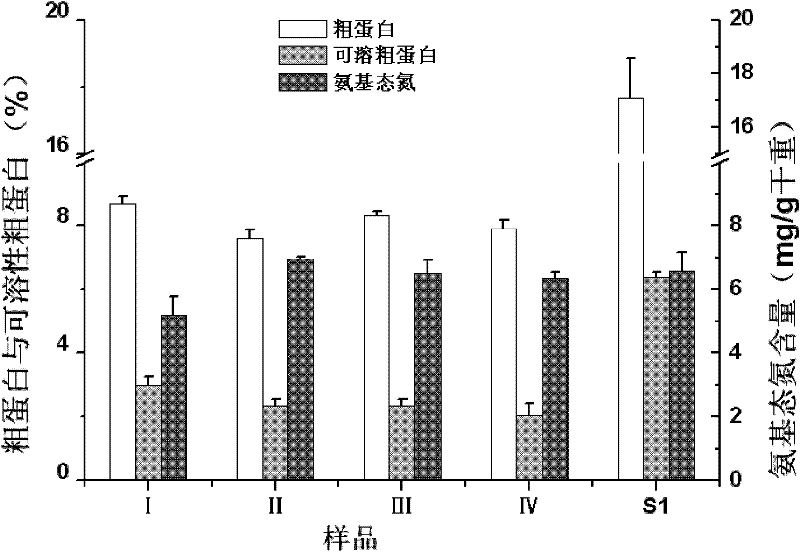

Image

Examples

preparation example Construction

[0023] The preparation method of the spore suspension of Mucor actinaechii is as follows: pour a small amount of solid PDA or red Bengal culture medium into the bottom of the triangular flask, pick a small amount of mycelia of Mucor actinomyces elegans for marking, and place it at 28°C for 3 days until the surface is covered by the mycelium It is better to have a large number of black spores, then add 100mL sterile water with a small amount of glass beads, shake for about 5 minutes until the hyphae start to peel off, and after the sterile water starts to become cloudy, filter through 4 layers of sterile gauze to another sterile triangle In the bottle, the spore suspension of Mucor actinomyces Yazhi was obtained, and the spore content was about 10 5 -10 6 cfu / mL.

[0024] The preparation method of Zymomonas mobilis suspension is as follows: put 50mL liquid PDA medium in the sterilized Erlenmeyer flask, insert a small amount of Zymomonas mobilis bacterial lawn with an inoculati...

Embodiment 1

[0026] (1) Fresh wet bean dregs are washed and squeezed to a water content of 75% (mass percentage);

[0027] (2) Put the squeezed bean dregs into the steam cabinet in layers, and cook for 20 minutes under normal pressure;

[0028] (3) Cool to room temperature after the steaming is completed, and the inoculation concentration is 10 5 cfu / mL of Mucor actinosa spore suspension 1ml and concentration 10 7 Add 2ml of cfu / mL Zymomonas mobilis suspension to 100g bean dregs, stir evenly, take 30g bean dregs and press into a ball;

[0029] (4) Ferment for 6 days in an artificial climate box, set the temperature at 18°C, and control the relative humidity at 90-95%, to obtain moldy bean dregs.

Embodiment 2

[0031] (1) Fresh wet bean dregs are washed and squeezed to a water content of 75% (mass percentage);

[0032] (2) put the squeezed bean dregs into the steam cabinet in layers, and cook for 15 minutes under normal pressure;

[0033] (3) Cool to room temperature after the steaming is completed, and the inoculation concentration is 10 5 cfu / mL of Mucor actinosa spore suspension 1ml and concentration 10 7 Add 2ml of cfu / mL Zymomonas mobilis suspension to 100g bean dregs, stir evenly, take 30g bean dregs and press into cake shape;

[0034] (4) ferment for 3 days in an artificial climate box, set the temperature at 28°C, and control the relative humidity at 90-95%, to obtain moldy bean dregs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com