Method for preparing high-gas tightness nickel-copper alloy for travelling wave tube

A nickel-copper alloy and high-airtight technology, which is applied in the field of preparing high-airtight nickel-copper alloys for traveling wave tubes, can solve the problem of poor airtightness of nickel-copper alloys, uneven distribution, and affecting the performance of nickel-copper alloy castings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

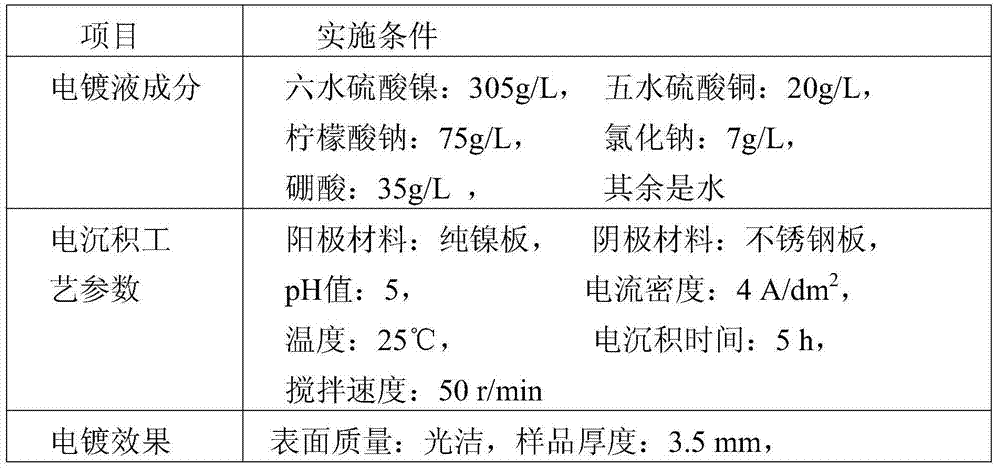

[0012] Example 1: Prepare the electroplating solution and set the electrodeposition process parameters according to the composition of the electroplating solution in Table 1, then electrodeposit nickel-copper alloy according to the above process steps.

[0013] Table 1 specific implementation conditions

[0014]

[0015]

example 2

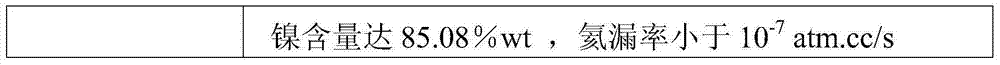

[0016] Example 2: Prepare the electroplating solution and set the electrodeposition process parameters according to the composition of the electroplating solution in Table 2, and then electrodeposit nickel-copper alloy according to the above process steps.

[0017] Table 2 specific implementation conditions

[0018]

example 3

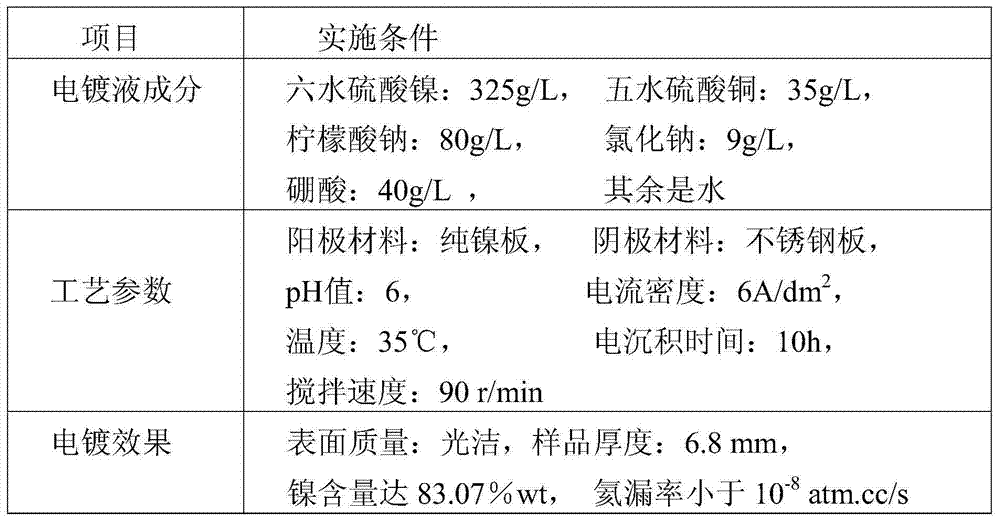

[0019] Example 3: Prepare the electroplating solution and set the electrodeposition process parameters according to the composition of the electroplating solution in Table 3, and then electrodeposit nickel-copper alloy according to the above process steps. Table 3 specific implementation conditions

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com