Compressor blade polishing equipment

A technology for compressor blades and equipment, used in grinding/polishing equipment, metal processing equipment, grinding racks, etc., can solve the problems of poor blade quality and consistency, low efficiency, worker injury, etc., and achieve the effect of uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

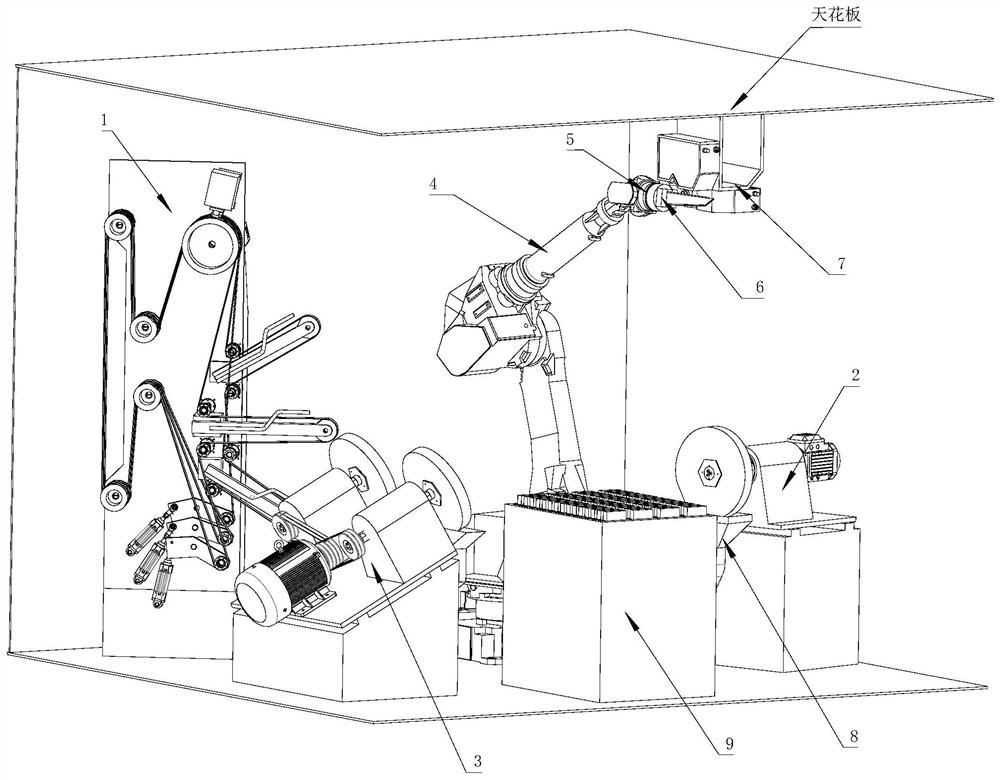

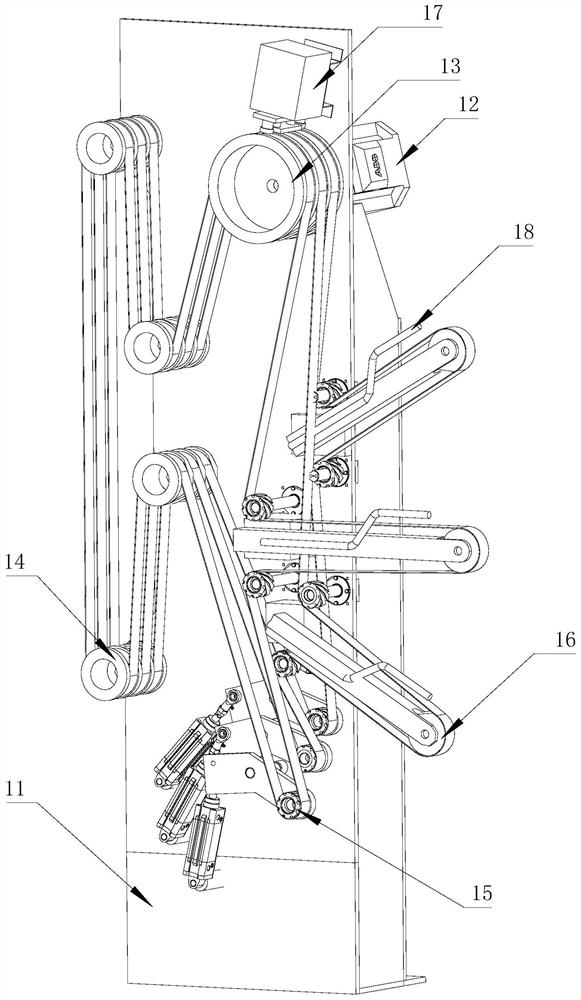

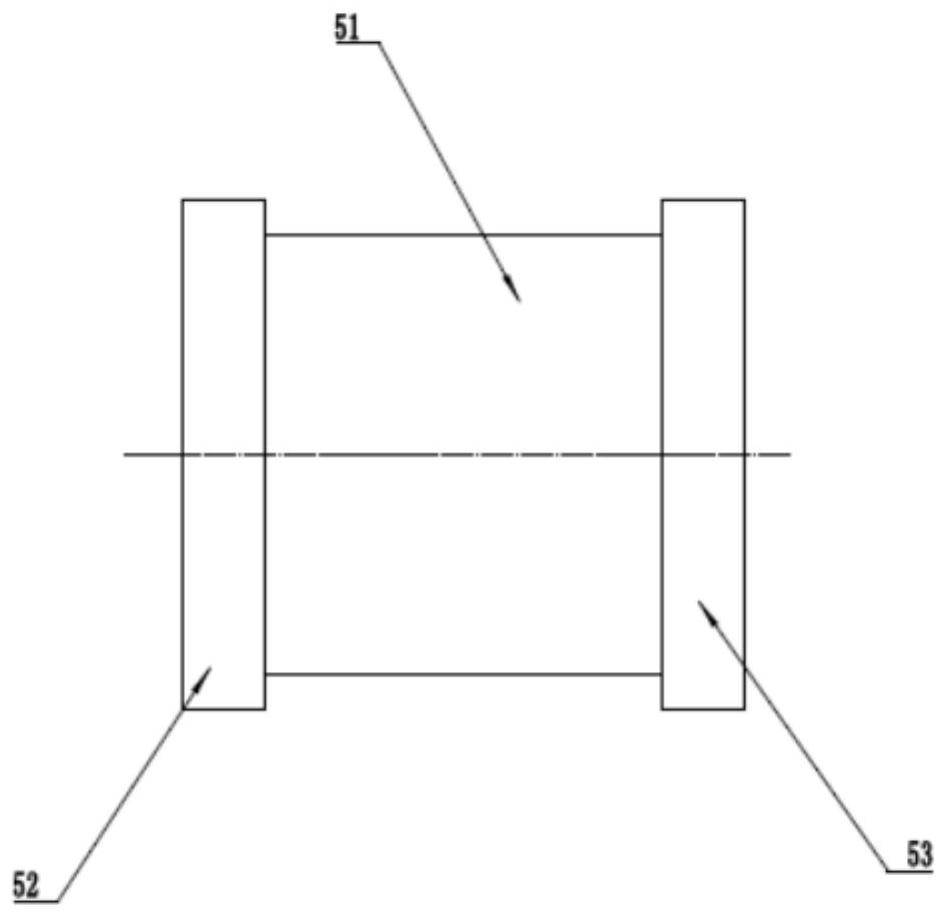

[0036] In order to set forth the present invention better, below with reference to appended Figure 1-7 The present invention is further described in detail.

[0037] Such as figure 1 Shown, a kind of compressor blade polishing equipment, it comprises:

[0038] Multi-station abrasive belt machine 1, first grinding wheel power slide 2, second grinding wheel power slide 3, polishing robot 4, six-dimensional force sensor assembly 5, blade fixture 6, three-dimensional laser detection device 7, dust collection device 8, Table 9 and intelligent control system 10.

[0039] Wherein, the blade clamp 6 is connected to the end effector of the polishing robot for clamping the blade;

[0040] Under the driving action, the polishing robot works so that different parts of the blades clamped by the blade clamps are respectively connected with the abrasive belt of the multi-station belt abrasive machine, the grinding wheel of the first grinding wheel power slide, and the second grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com