Method of preparing purslane polyunsaturated fatty acids from purslane residues

A technology of unsaturated fatty acid and purslane slag, which is applied in the preparation of purslane polyunsaturated fatty acid and the extraction and preparation of polyunsaturated fatty acid, which can solve the problems of unsuitability for large-scale industrial production, high cost, and large energy consumption. problems, to achieve the effect of moderate particle size, overcome technical bottlenecks, fine and uniform powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

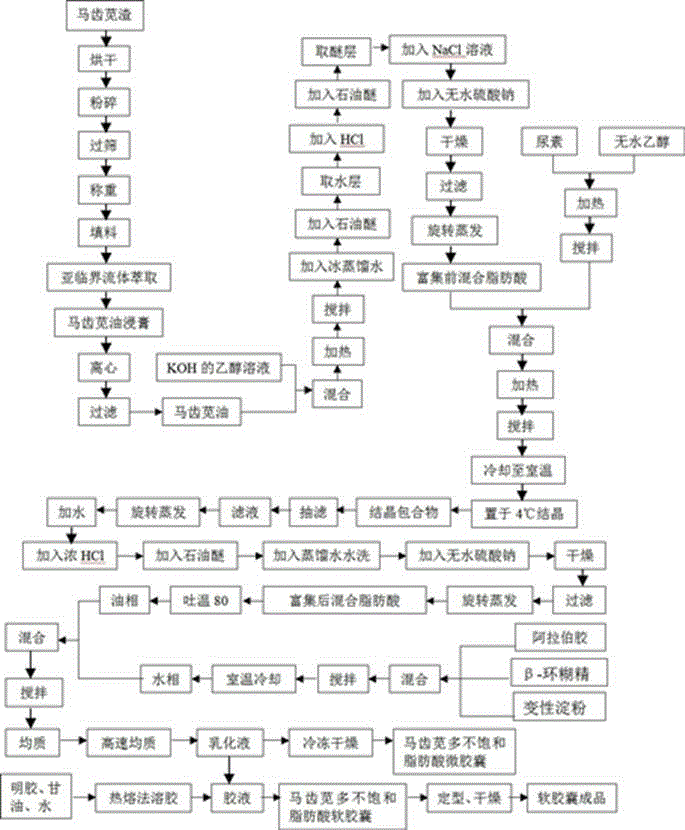

[0046] Embodiment one: the preparation of purslane polyunsaturated fatty acid microcapsule

[0047] % According to weight percentage, the specific method steps of preparing purslane polyunsaturated fatty acid microcapsules from purslane slag are as follows:

[0048] (1) Preparation of purslane slag: using fresh purslane and drinking water as the main raw materials, fresh purslane is selected, cleaned, chopped, soaked in water at a ratio of 1:3 by weight for 12 hours, and boiled at 80°C Boil for 6 hours, filter to obtain purslane slag.

[0049] (2) Pretreatment using purslane slag as raw material: use purslane slag in the processing and production of purslane or the purslane slag provided in the above steps as raw material, dry at 70°C, crush, and sieve to 60 mesh , weighing, filling.

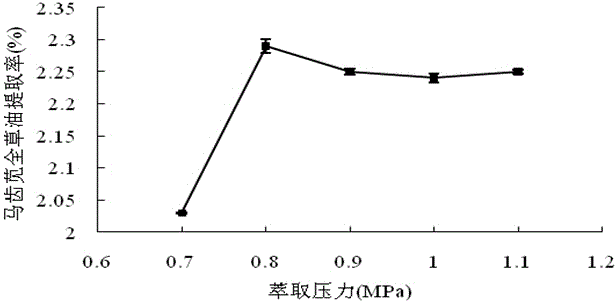

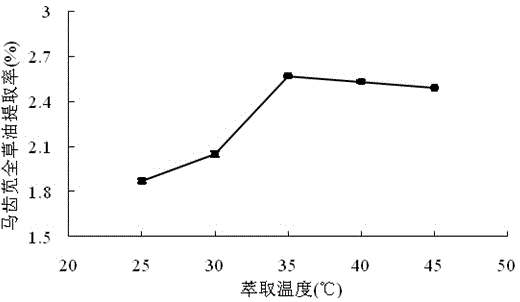

[0050] (3) Subcritical isobutane extraction technology to extract purslane oil: Carry out subcritical fluid extraction process, set conditions, extraction pressure 0.8MPa, extraction temper...

Embodiment 2

[0055] Embodiment two: the preparation of purslane polyunsaturated fatty acid soft capsule

[0056] % According to weight percentage, the specific method steps of preparing purslane polyunsaturated fatty acid soft capsules from purslane slag are as follows:

[0057] (1) Preparation of purslane slag: fresh purslane and drinking water are used as main raw materials. Fresh purslane is selected, cleaned, chopped, soaked in water at a ratio of 1:3 by weight for 12 hours, and boiled at 80°C Boil for 6 hours, filter to obtain purslane slag.

[0058] (2) Pretreatment using purslane slag as raw material: use purslane slag in processing and production of purslane or purslane slag prepared in the above steps as raw material, dry at 70°C, crush, and sieve to 60 mesh , weighing, filling.

[0059] (3) Subcritical isobutane extraction technology to extract purslane oil: Carry out subcritical fluid extraction process, set conditions, extraction pressure 0.8MPa, extraction temperature 40°...

Embodiment 3

[0064] Embodiment three: the preparation of purslane polyunsaturated fatty acid microcapsule and soft capsule

[0065] % by weight percentage, the concrete method steps of purslane polyunsaturated fatty acid microcapsule and soft capsule are as follows:

[0066] (1) Pretreatment using purslane slag as raw material: fresh purslane and drinking water are used as the main raw materials. Fresh purslane is selected, cleaned, chopped, and soaked in water at a ratio of 1:3 by weight for 12 hours. Boil at 80°C for 6 hours, filter to obtain purslane slag, or use the purslane slag in the processing and production of purslane as raw material, dry the purslane slag at 70°C, crush, sieve 60 mesh, weigh, and fill .

[0067] (2) Extraction of purslane oil by subcritical isobutane extraction technology: Subcritical fluid extraction process is adopted, and the set conditions are: extraction pressure 0.8MPa, extraction temperature 40°C, extraction 150min, and the extracted purslane oil is so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com