Nanometer material contained ladle bottom argon blowing permeable brick and preparation process thereof

A nano-material and bottom-blowing argon technology, which is applied in the field of refractory materials, can solve the problems of air-permeable bricks losing their air-permeable function, affecting the normal smelting of steel plants, and unsmooth air blowing, etc., achieving good anti-stripping effect, good social and economic benefits , reduce the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

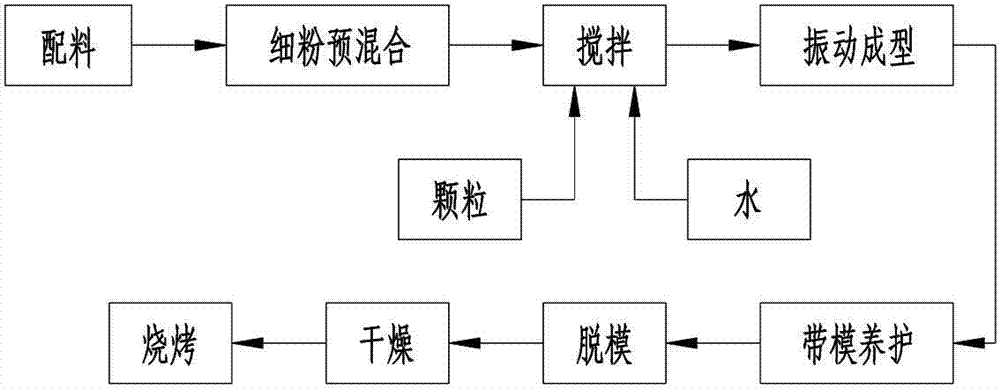

Method used

Image

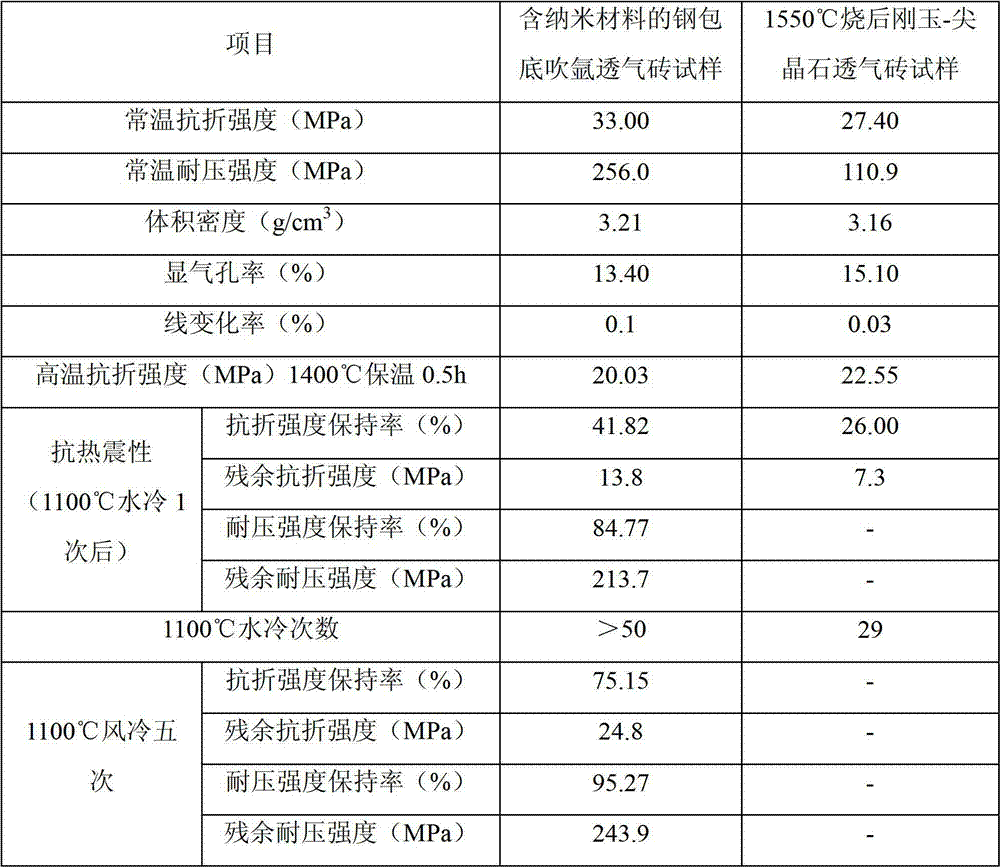

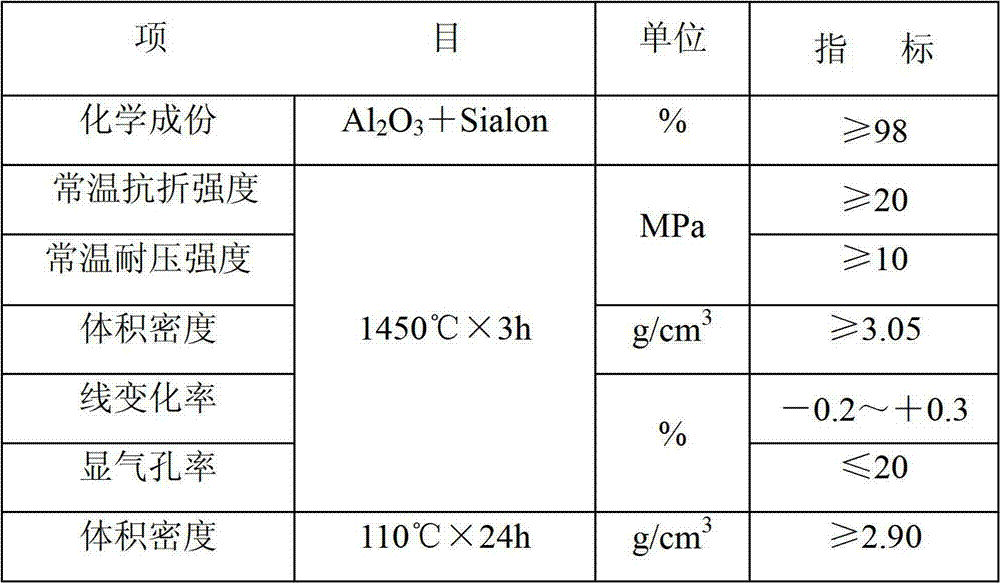

Examples

Embodiment 1

[0089] Embodiment 1: This embodiment is the best embodiment of the present invention.

[0090] An argon-blown air-permeable brick containing nano-materials at the bottom of a ladle, which includes the following components and the weight ratio of each component is:

[0091] High purity corundum 76.1,

[0092] Spinel 6,

[0093] α-Al 2 O 3 Micropowder 7,

[0094] Nano calcium carbonate 0.4,

[0095] Si powder 6,

[0096] Bonding agent 4.5,

[0097] Explosion-proof agent 0.08;

[0098] The high purity corundum includes tabular corundum and fused white corundum, and the weight ratio of tabular corundum to fused white corundum is 62:14.1, and the tabular corundum includes tabular corundum with a particle size of 3-6mm The weight ratio of particles A, plate corundum particles B with a particle diameter of 1 to 3 mm, and plate corundum particles C with a particle diameter of 0 to 1 mm, and the weight ratio of plate corundum particles A, plate corundum particles B and plate corundum particles C f...

Embodiment 2

[0136] An argon-blown air-permeable brick containing nano-materials at the bottom of a ladle, which includes the following components and the weight ratio of each component is:

[0137] High purity corundum 70,

[0138] Spinel 3,

[0139] α-Al 2 O 3 Micropowder 10,

[0140] Nano calcium carbonate 0.6,

[0141] Si powder 4,

[0142] Bond 7,

[0143] Explosion-proof agent 0.05;

[0144] The high-purity corundum includes tabular corundum and fused white corundum, and the weight ratio of tabular corundum to fused white corundum is 60:16, and the tabular corundum includes tabular corundum with a particle size of 3-6 mm. The weight ratio of particles A, plate corundum particles B with a particle diameter of 1 to 3 mm, and plate corundum particles C with a particle diameter of 0 to 1 mm, and the weight ratio of plate corundum particles A, plate corundum particles B and plate corundum particles C for:

[0145] Tabular corundum particles A 25,

[0146] Tabular corundum particles B 18,

[0147] Tabul...

Embodiment 3

[0182] An argon-blown air-permeable brick containing nano-materials at the bottom of a ladle, which includes the following components and the weight ratio of each component is:

[0183] High purity corundum 80,

[0184] Spinel 9,

[0185] α-Al 2 O 3 Micro powder 5,

[0186] Nano calcium carbonate 0.2,

[0187] Si powder 8,

[0188] Bonding agent 2,

[0189] Explosion-proof agent 0.1;

[0190] The high-purity corundum includes tabular corundum and fused white corundum, and the weight ratio of tabular corundum to fused white corundum is 65:2, and the tabular corundum includes tabular corundum with a particle size of 3-6mm The weight ratio of particles A, plate corundum particles B with a particle diameter of 1 to 3 mm, and plate corundum particles C with a particle diameter of 0 to 1 mm, and the weight ratio of plate corundum particles A, plate corundum particles B and plate corundum particles C for:

[0191] Tabular corundum particles A 30,

[0192] Tabular corundum particles B 23,

[0193] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com