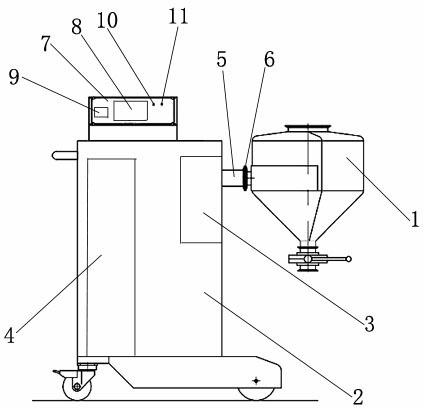

Laboratory hopper mixing machine

A mixer, laboratory technology, applied in mixers, mixing methods, mixers with rotating containers, etc., can solve the problems of inability to achieve mixing effect, inability to set and adjust the speed of rotation, and achieve the effect of optimal mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further reveal the technical solution of the present invention, the implementation mode of the present invention is now described in detail in conjunction with the accompanying drawings: as figure 1 As shown, a laboratory hopper mixer includes a hopper 1, a machine base 2, a rotary system 3 and a control system 4 located in the machine base 2, a rotary shaft 5 is provided on one side of the machine base 2, and the rotary shaft 5 is connected to the rotary shaft. The system 3 is connected, the hopper 1 is installed on the rotary shaft 5 in a cantilever fixed manner, the hopper 1 and the rotary axis form an included angle of 30°, and an induction element 6 is provided on the rotary shaft 5 assembly. An operation panel 7 is arranged on the top of the base 2, and the operation panel 7 is provided with a touch screen 8, a printer 9, a power switch 10 and an emergency stop switch 11 for displaying running time, rotating speed and accumulated revolutions. The slewi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com