Fabric softening compositio

A technology of softening composition and fabric softener, applied in the direction of softening composition, detergent composition, organic cleaning composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

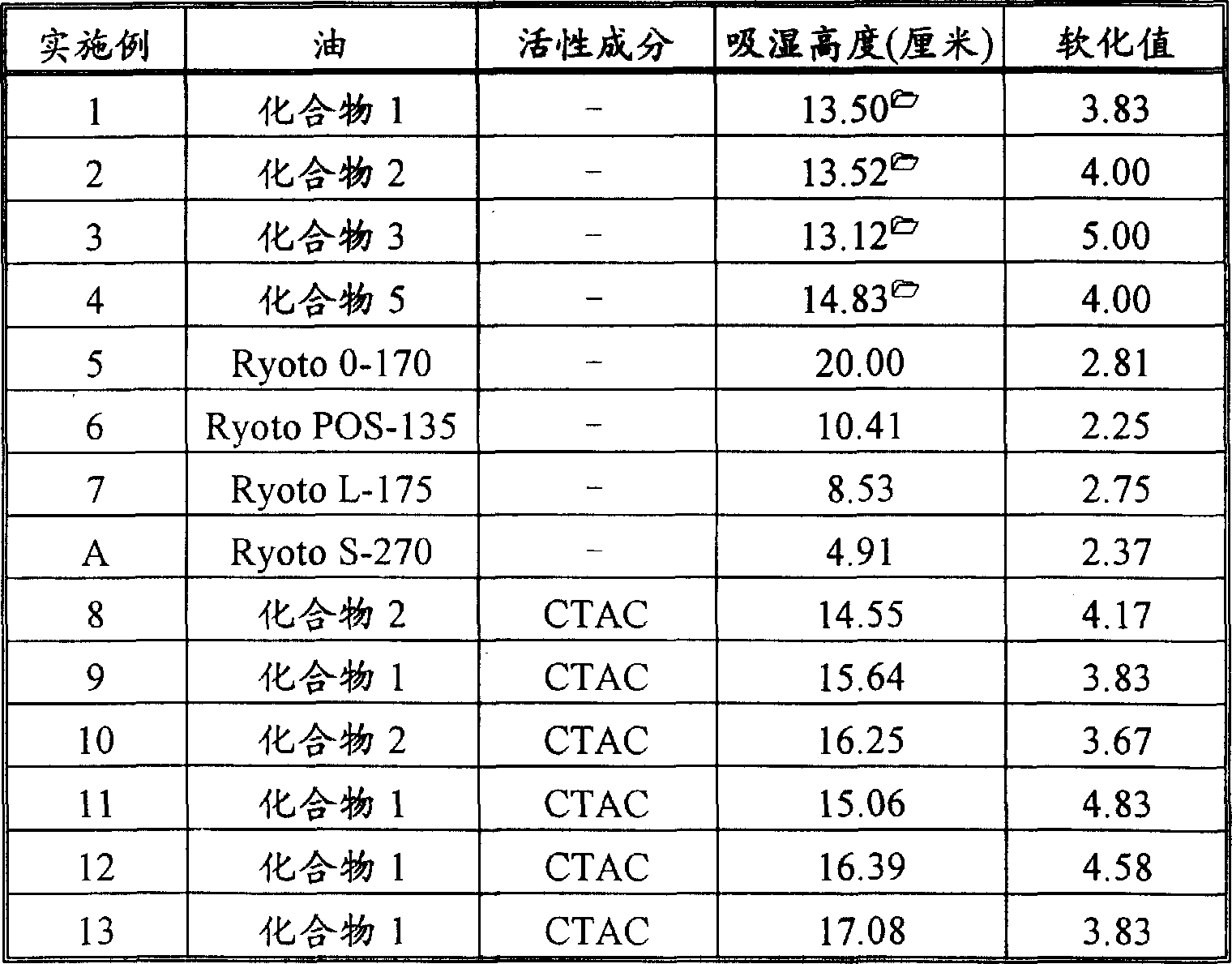

Image

Examples

Embodiment

[0070] The invention is illustrated by the following non-limiting examples. Other embodiments suitable within the scope of the present invention will also be apparent to those of ordinary skill in the art. A. Preparation of CPE and RSE Compound 1

[0071] Glucopentaester was prepared in which 50% (approximately) of the ester groups were acetyl and 50% (approximately) decanoyl.

[0072] α-D Glucose (0-111M) was added to pyridine at room temperature. Acetyl chloride (0.254M) and decanoyl chloride (0.278M) were mixed, and the acid chloride mixture was added dropwise to the glucose solution, and the acid chloride was added slowly over about 1.5 hours. During the course of the reaction, a large amount of white turbid precipitate was formed, and ethyl acetate was added to maintain the fluidity of the reaction mixture.

[0073] The reaction mixture was stirred overnight (>16 hours) at room temperature. The reaction mixture was filtered to remove solid pyridine hydrochloride and e...

Embodiment 48 and 49

[0115] Examples 48 and 49 Prepare aqueous emulsions / dispersions containing 5% active ingredient containing a mixture of fabric softener and sucrose ester in a ratio of 1:4. 0.3% fragrance was added to the composition and the persistence of the fragrance was determined. See Table 11 below.

[0116] Example

the fabric

softener

Sucrose esters

essence

Moisturizing oil 5 hours 24 hours

48

CTAC

Sucrose pentaoleate

(Ryoto 0-170) Liquid

appropriate

appropriate

appropriate

49

HEQ

abovementioned

Sucrose pentastearate

3.0

2.4

1.76

H

HEQ

-

3.1

1.9

1.19

[0117] Fragrance intensity was measured by a trained panel, with Example 48 being measured alone. The fabrics were scored on a scale of 0-5. 5 being extremely strong scent and 0 being no perceptible scent. Perfume concentration was evaluated immed...

Embodiment 51

[0120] A series of water emulsions / dispersions containing 5% active ingredient were prepared in Example 51, containing 4.5% sucrose tetraerucate (same as Example 50) in the active ingredient, 0.5% nonionic surfactant deposition aid ( Synperonic A7) and less than 0.2% deflocculant polymer (both cationic): Example 51a Celquat SC240 (from National Starch & Chemical) Example 51b Coltide HQS (from Croda Colloids) Example 51c Coltide QS (from Croda Colloids) Example 51d Poly DMDAAC:EHA (from National Starch) - 10:1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com