Patents

Literature

54results about How to "Not easy to moth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of air spinning cotton core filament covering yarn

The invention discloses a production technology of air spinning cotton core filament covering yarn.The production technology comprises the following technological steps that 1, core filament fibers are prepared into core filaments through cotton opening and scotching, cotton carding, drawing and doubling and air spinning; 2, outer wrapping fibers are prepared into skin yarn through cotton opening and scotching, cotton carding, drawing and doubling and rough yarn obtaining; 3, the core filaments obtained in the step 1 and the skin yarn obtained in the step 2 are fed into a covering yarn device arranged in ring spun yarn equipment to be prepared into covering yarn; 4, the covering yarn is prepared into the finished air spinning cotton core filament covering yarn through a winding process, wherein cotton fibers are adopted as the core filament fibers.According to the preparation technology of the covering yarn, air spinning cotton yarn is adopted as the core filaments, and therefore the finished yarn is high in hygroscopicity, good in dyeing performance, soft in handfeel, comfortable to wear, simple in appearance, not prone to worm damage, firm and durable; due to the fact that the air spinning yarn is high in fluffy degree, the finished yarn obtained by wrapping the air spinning yarn through ring spinning has the unique style of being soft outside and rigid inside, and a fabric is stiff and smooth and comfortable.

Owner:江阴市茂达棉纺厂有限公司

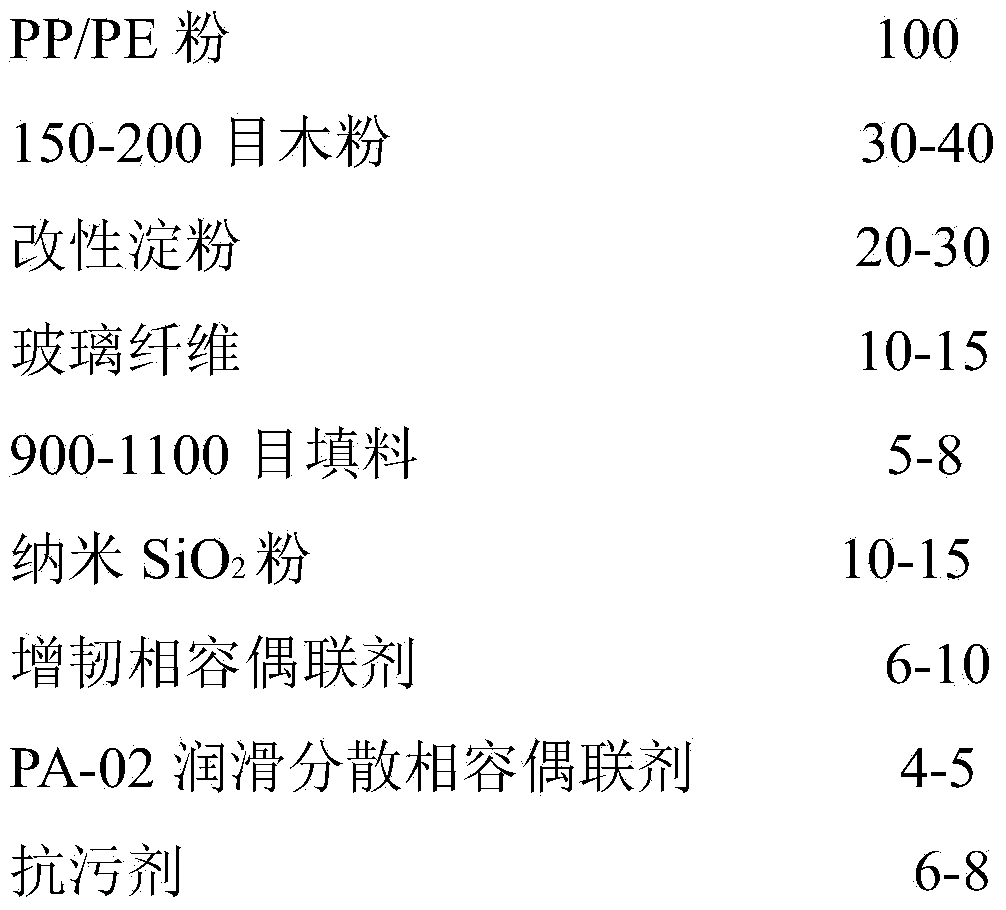

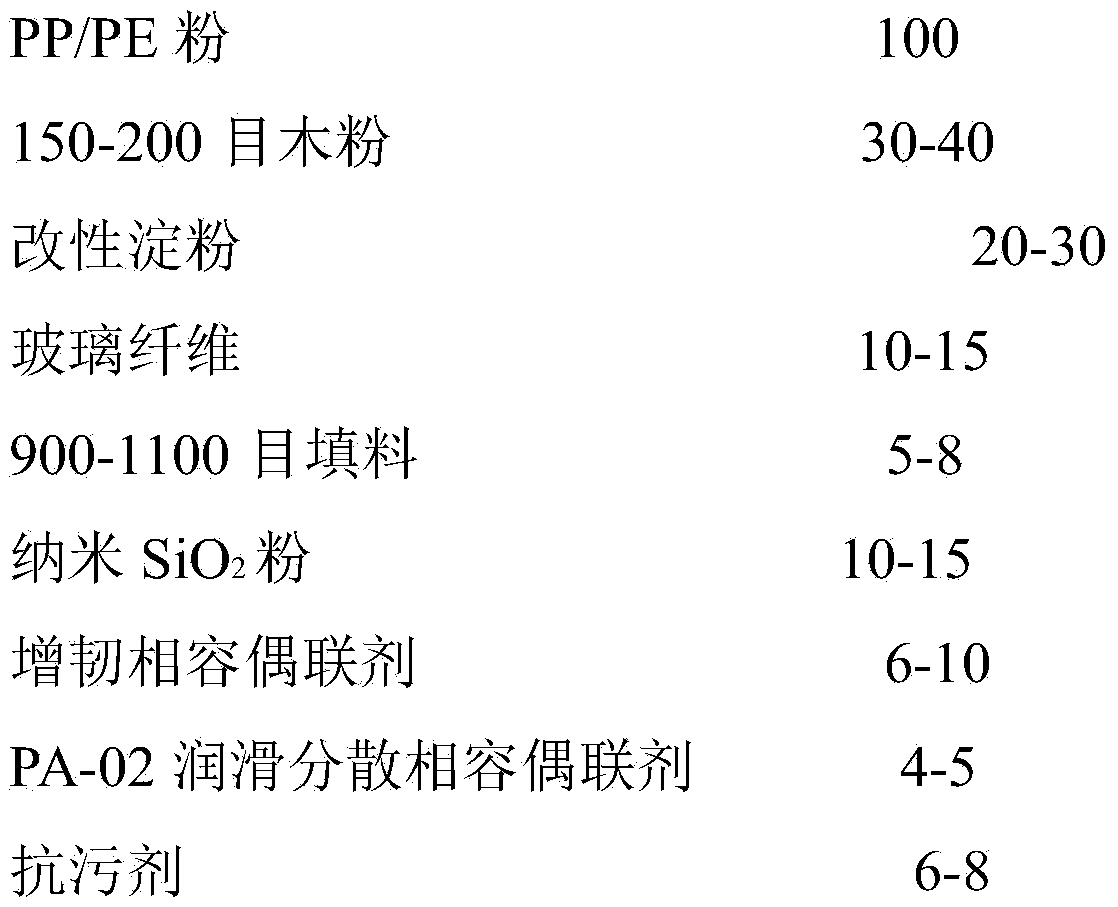

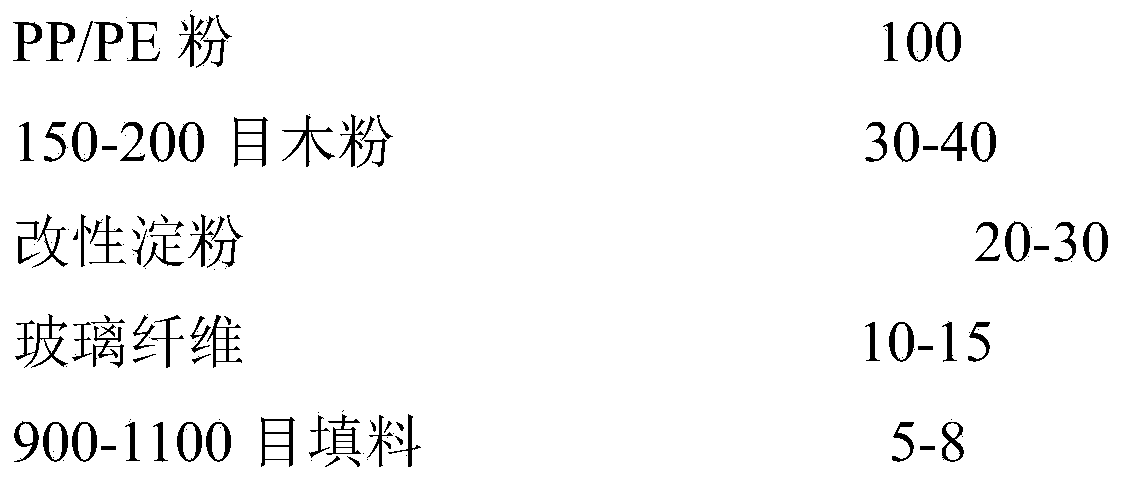

Preparation method of degradable anti-pollution wood plastic material and product

The invention discloses a preparation method of a degradable anti-pollution wood plastic material. The preparation method comprises the following steps: 1) preparing the components in parts by weight: 100 parts of PP / PE powder, 30-40 parts of (150-200)-mesh wood flour, 20-30 parts of modified starch, 10-15 parts of glass fibers, 5-8 parts of (900-1100)-mesh filler, 10-15 parts of nano SiO2 powder, 6-10 parts of toughening compatible coupling agent, 4-5 parts of PA-02 lubricative dispersing compatible coupling agent and 6-8 parts of anti-pollution agent; and 2) highly mixing the PP / PE powder, the (150-200)-mesh wood flour, the modified starch, the glass fibers, the (900-1100)-mesh filler and the nano SiO2 powder to 100-120 DEG C; after fully mixing, adding the PA-02 lubricative dispersing compatible coupling agent, the toughening compatible coupling agent and the anti-pollution agent and mixing to 120-140 DEG C; and after fully mixing, cooling to 30-50 DEG C and granulating to form the degradable anti-pollution wood plastic material. The mechanical properties of the material disclosed by the invention are adjusted by virtue of proportion of the glass fibers and the filler, the degradable environment-friendliness is adjusted by virtue of proportion of the plastic, the modified starch and the wood flour, and finally, the anti-pollution performance is enhanced by virtue of the nanoscale silicon dioxide and anti-pollution agent.

Owner:GUANGDONG HONGYUN FURNITURE CO LTD +3

Preparation method of miniature marine animal plastinated specimens

InactiveCN104041483APromote absorptionPrevent corruptionDead animal preservationHuman bodyCuttlefish

The invention discloses a preparation method of miniature marine animal plastinated specimens. By the method for preparing specimens, instruments and equipment used are simple; vacuum drying and pressurization and osmotic treatment are not required; plastination time is shortened; the preparation process is simpler and easier to operate; and no reagent which is harmful to human body is also not used during the preparation process. Miniature marine animal plastinated specimens of short-necked clam, comb shell, chlamys farreri, oyster drill, hermit crab, Octopus, cuttlefish, sea catfish and the like, that are finished by the above plastination technology, has long storage time, can be directly contacted and have true forms. The specimens can be widely applied in fields of teaching job, scientific research and collecting and appreciating.

Owner:DALIAN UNIV

Raw material formula for regenerated plates

The invention relates to a raw material formula for regenerated plates, which is characterized in that the raw material formula comprises the following components by weight percent: 15-20% of polymer materials; 55-70% of crop fiber powder; 2-8% of modifier and 10-20% of adjuvant additives. The raw material formula has the advantages that the regenerated plates produced according to the raw material formula have high hardness and strength, acid and alkali resistance, corrosion resistance, no formaldehyde, difficult deformation, moth proofing property, low cost, recyclability, long service life and wide range of applications.

Owner:上海泷晟环保科技有限公司

Color fixing and plasticizing method for plant leaf blade specimen

InactiveCN101196443ANot easy to fadeUnbreakableDead plant preservationPreparing sample for investigationAcetic acidYellow green color

The invention discloses a herbarium fixing and plasticizing method, which comprises the following procedures: color fixing procedure: A. heating the green plant leaves in copper acetate aqueous solution until the herbarium changing into chartreuse and green again, and using clean water to flush the leaves of plant; or B. heating the leaves of red plant leaves in acetic acid magenta until the plant leaves become yellow and red again, using clean water to flush the plant leaves; or C. heating the plant leaves in 50 percent acetum until the plant leaves become yellow, and using clean water to flush the plant leaves; plasticizing procedure, putting the product in the color fixing procedure into methacrylic acid methyl ester solution for immersing for 1 to 10 hours and shining by sunlight for 5 to 24 hours. The plant leaves specimens manufactured by the plant leaves specimens color fixing and plasticizing method are not easy to fade, break or be damaged by worm, and is not easy to milden and rot.

Owner:华东师范大学第二附属中学

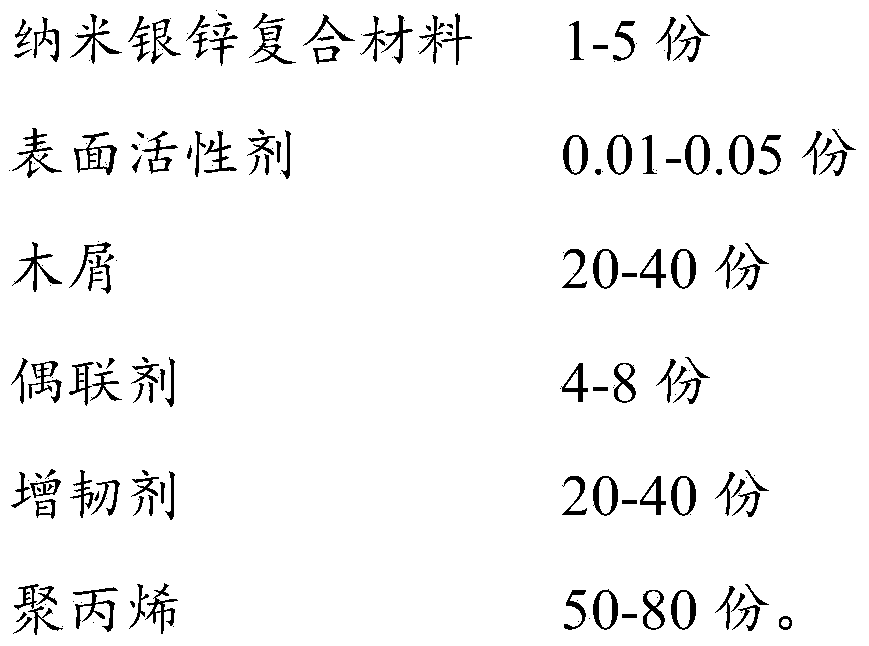

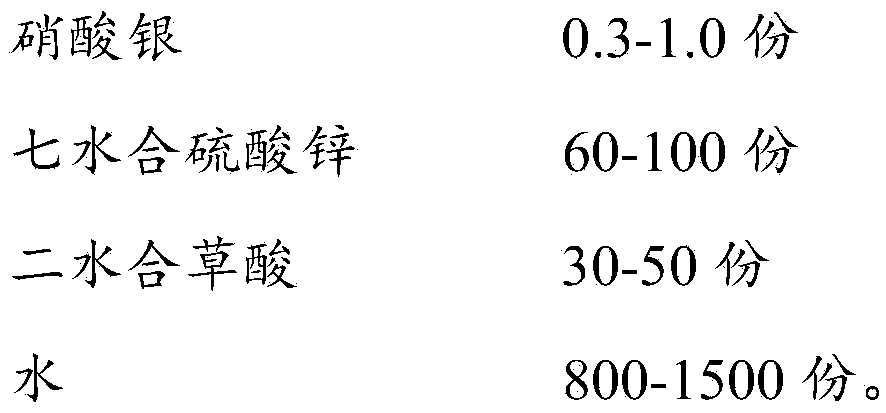

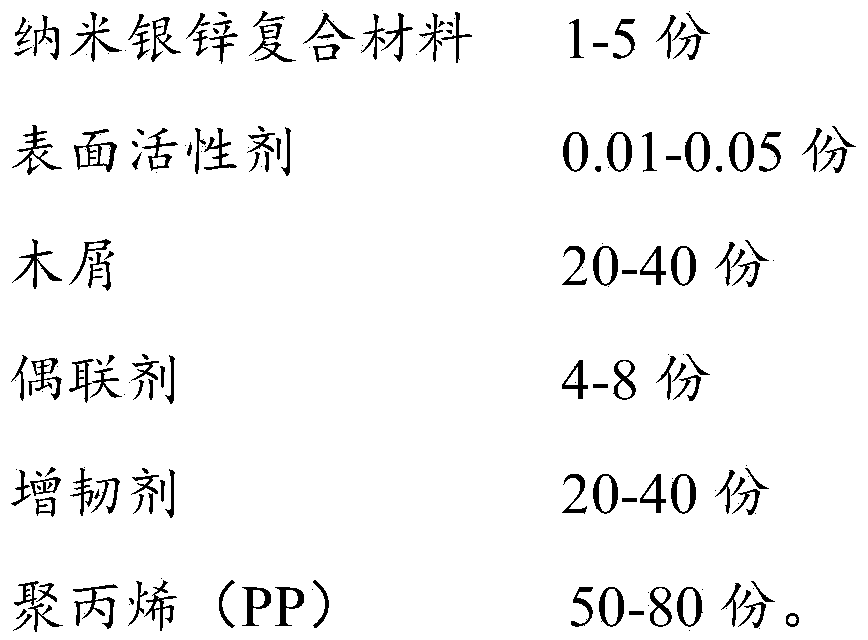

Environment-friendly nano antibacterial wood plastic composite and preparation method thereof

InactiveCN105367895AGood antibacterial and antifungal effectGood compatibilityCouplingFlexural strength

The invention discloses an environment-friendly nano wood plastic composite, which includes the following components by weight: 1-5 parts of nano silver zinc composite, 0.01-0.05 part of a surfactant, 20-40 parts of sawdust, 4-8 parts of a coupling agent, 20-40 parts of a toughening agent and 50-80 parts of polypropylene (PP). The environment-friendly nano antibacterial wood plastic composite employs nano silver and zinc composite material to modify sawdust, in order to improve the antibacterial and antifungal properties of the wood plastic composite; and a suitable coupling agent is used for pretreating the hydroxyl and amino groups on the sawdust surface to improve the compatibility of sawdust with a non-polar matrix such as polypropylene, thereby greatly improving the mechanical properties of tensile strength, flexural strength and impact strength of the wood plastic composite. Therefore, the environment-friendly nano antibacterial wood plastic composite is green and environment-friendly, and has the advantages of good mechanical, antifungal and mildew-proof properties, no worm damage and long service life.

Owner:泉州斯达纳米科技发展有限公司

Anti-moth finishing agent for rabbit hair fabric

InactiveCN106087397AQuality assuranceGood light fastnessGrip property fibresAnimal fibresCitrate sodiumChemistry

The invention discloses an anti-moth finishing agent for rabbit hair fabric. The finishing agent is prepared by the following raw materials in parts by weight: 5-6 parts of sophorolipids, 4-8 parts of polyoxyethylene rosin ester, 3-7 parts of hydroxypropyl xanthan gum, 2-6 parts of poloxamer, 5-10 parts of methylene dithiocyanate, 3-6 parts of epichlorohydrin, 2-4 parts of a cross-linking agent, 15-20 parts of 2-methyl-4-isothiazoline-3-ketone, 4-8 parts of sodium citrate, 12-16 parts of natural saponins, 2-6 parts of an antifoaming agent, 7-11 parts of vinyltrimethoxy silane, 10-12 parts of a coupling agent, and 15-20 parts of sodium carbonate. The anti-moth finishing agent for rabbit hair fabric can effectively guarantee quality of rabbit hair fabric, so that the fabric is not easy to be damaged by moths, and the anti-moth time efficiency is longer than 2 years or more; the anti-moth finishing agent has good light resistance, and does not harm environment and human.

Owner:HUZHOU HONGXIN SILK FACTORY

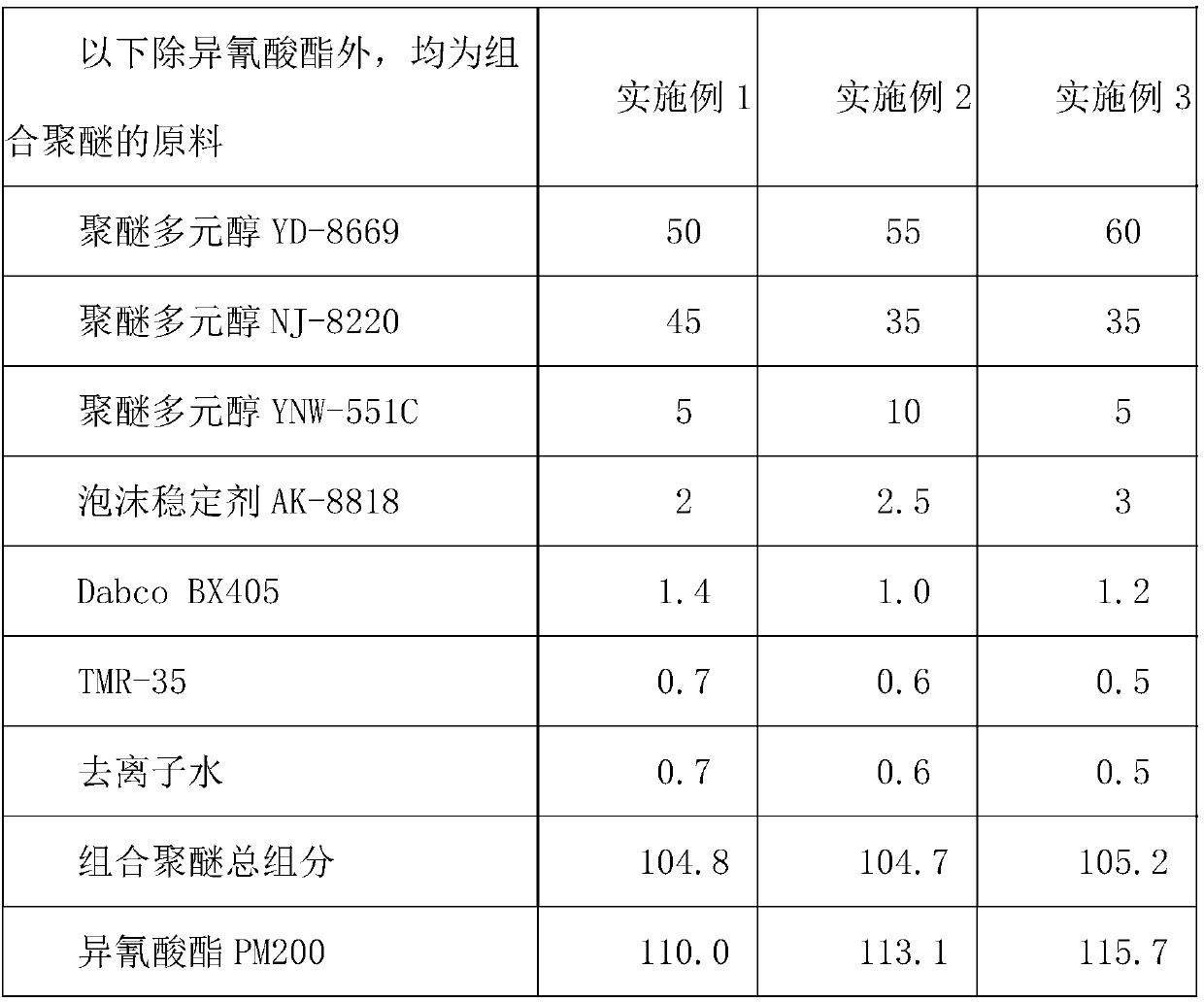

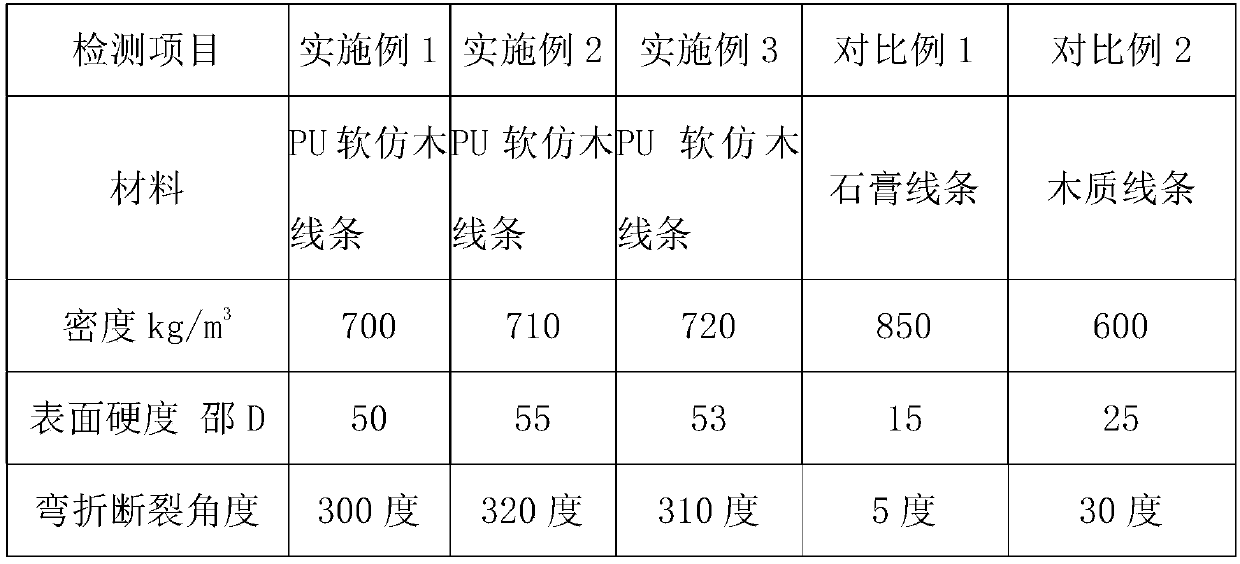

Premixed polyether polyol, polyurethane raw material composition and polyurethane foam for polyurethane imitated wood product and preparation method of polyurethane foam

The invention relates to premixed polyether polyol, polyurethane raw material composition and polyurethane foam for a polyurethane imitated wood product and a preparation method of the polyurethane foam. The premixed polyether polyol is prepared from components in parts by weight as follows: 50-60 parts of first polyether polyol, 35-45 parts of second polyether polyol, 5-10 parts of third polyether polyol, 2-3 parts of a foam stabilizer, 1.5-2.5 parts of a catalyst and 0.5-0.7 parts of a foaming agent, wherein viscosity of first polyether polyol is 3200 plus or minus 500 mPa.s and hydroxyl value is 425-455 mgKOH / g when first polyether polyol is at 25 DEG C; viscosity of second polyether polyol is 1500 plus or minus 500 mPa.s and hydroxyl value is 400-460 mgKOH / g when second polyether polyol is at 25 DEG C; viscosity of third polyether polyol is 500 plus or minus 100 mPa.s and hydroxyl value is 54.5-57.5 mgKOH / g when third polyether polyol is at 25 DEG C. The polyurethane imitated woodproduct prepared from premixed polyether polyol has the advantages of being high in toughness, bendable and suitable for dome, arc-shaped furniture / wall decoration and the like.

Owner:SHANGHAI DONGDA POLYURETHANE

Process for producing regenerated plates

InactiveCN101722558AHigh hardnessHigh strengthWood working apparatusDomestic articlesFiberPolymer science

The invention relates to a process for producing regenerated plates, which is characterized in that the process comprises the following steps: 1) mixing polymer materials, crop fiber powder, a modifier and adjuvant additives, and forming a mixture; 2) adding the mixture into a heating device; 3) starting the heating device; 4) smashing the high-temperature mixture, and then sending into a material tube of a single-screw extruder; 5) sending the high-temperature mixture into the material tube of the single-screw extruder; and 6) using the single-screw extruder to extrude the mixture into a mold, carrying out extrusion molding treatment, and then forming the regenerated plates with special shapes. The process has the advantages that the regenerated plates produced by the production process have high hardness and strength, acid and alkali resistance, corrosion resistance, no formaldehyde, difficult deformation, moth proofing property, low cost and good elasticity.

Owner:上海泷晟环保科技有限公司

Method for preparing bamboo mat used for external cable packaging

InactiveCN107443529APrevent bacterial regenerationNot easy to mothWood treatment detailsCane mechanical workingUreaChemistry

The invention discloses a method for preparing a bamboo mat used for external cable packaging. The method includes the following steps that branches and leaves of bamboo are removed, the bamboo is split to form bamboo chips, and the bamboo chips are dried to obtain pretreated bamboo; the pretreated bamboo is placed into a hydrochloric acid solution and subjected to standing, then filtering and natural air drying are conducted, and a product is placed into a sodium hydroxide solution and subjected to standing, so that a material A is obtained; the material A is carbonized, and then a product is delivered to a hot press to be flattened to form a material B; and the material B is delivered into an ethanol solution, cocamidopropyl betaine and butyl titanate are added into the ethanol solution and stirred, hydrochloric acid, urea, citric acid complexing silver nitrate and microcrystalline wax are added, and then heated stirring, filtering, washing, drying and knitting are conducted, so that the bamboo mat used for external cable packaging is obtained. The method can completely kill bacteria and eggs in bamboo and effectively soften a bamboo fiber bundle, so that the stability of the formed bamboo mat in use is guaranteed; meanwhile, the sterilization and antibacterial effects of bamboo fibers are effectively improved, the bamboo fibers are prevented from absorbing moisture and gas in air, and the effects of corrosion prevention and deformation prevention are achieved.

Owner:广德县泉村竹制品有限公司

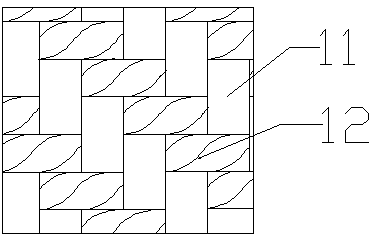

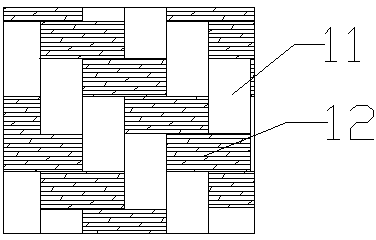

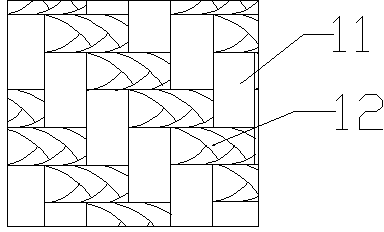

Fabric

InactiveCN104856301ANovel shape and styleStylish shapeProtective garmentSpecial outerwear garmentsFiberYarn

The invention relates to a fabric which comprises a terylene fabric and a flocked chenille yarn fabric, wherein the terylene fabric serves as inner lining; the flocked chenille yarn fabric serves as an outer layer; the terylene fabric and the flocked chenille yarn fabric are connected through sewing. The fabric is characterized in that a bamboo fiber fabric layer formed by interweaving and blending warps and wefts covers the outer surface of the terylene fabric. The fabric is novel and fashionable in shape and format, bright in color, not monotonous, and easy to clean, can be matched with high-grade clothing, and can meet the requirement of modern young beauty-pursuing women; placing of lace serving as an ornament on the surface of the fabric can be avoided, so as to meet the kneepad requirement of numerous men. The fabric is simple in production process, high in quality, stiff, smooth, anti-wrinkle, high in strength, wear resistant, poor in moisture absorption, dried fast, moth-proof, mildew and rot resistant, and easy to store.

Owner:黄勤

Preparation method of bamboo mat not prone to deformation

InactiveCN108407015APrevent regenerationAvoid absorptionWood treatment detailsCane mechanical workingPolyvinyl alcoholCarbonization

The invention discloses a preparation method of a bamboo mat not prone to deformation. The method comprises the following steps: S1, carrying out carbonization treatment of a pretreated bamboo, then feeding the bamboo into a hot press and flattening the bamboo to obtain the carbonized bamboo, wherein the carbonization treatment is characterized by feeding the bamboo into a drying and disinfectingcarbon dryer, the heating temperature of the drying and disinfecting carbon dryer is 160-190 DEG C, the heating time is 2-4 hours, and the bamboo is carbonized at a carbonization degree of 5-30%; andS2, feeding the carbonized bamboo into an ethanol solution, adding soyabean lecithin and tetraisopropyl titanate, then stirring, adding hydrochloric acid, tartaric acid complex copper nitrate and polyvinyl alcohol, increasing the temperature and stirring, filtering, washing, drying and knitting to obtain the bamboo mat not prone to deformation.

Owner:施文杰

Free dummy and manufacture method thereof

The invention discloses a free dummy and a manufacture method thereof. The method comprises the steps of mould manufacturing, dough manufacturing, head-neck and hand-foot manufacturing, trunk manufacturing, coloring manufacturing, clothes manufacturing and dummy assembly, wherein the dough prepared by special mixture ratio is used for manufacturing the head-neck and hand-foot of the dummy through the mould, a flexible metal wire is wound into a trunk bracket with structure shaped like a Chinese character 'mu' (wood in English), plastic foam or sponge is filled at the metal wire truck bracket and fixed on the metal wire, and then the free dummy is obtained and the manufacture thereof is achieved by the assembly of the dummy head-neck, hands, feet, chest, clothes and each part of the metal wire trunk bracket. The invention has the beneficial effects that the free dummy has simple manufacture steps, the dough is not easy to fade and be damaged by vermin, the dummy detail manufacture can be fine and the plasticity is strong, the action shape of the dummy can be set by bending randomly at any time according to different scenes, and large-scale dummy assembly scene is simple and beautiful.

Owner:张怡

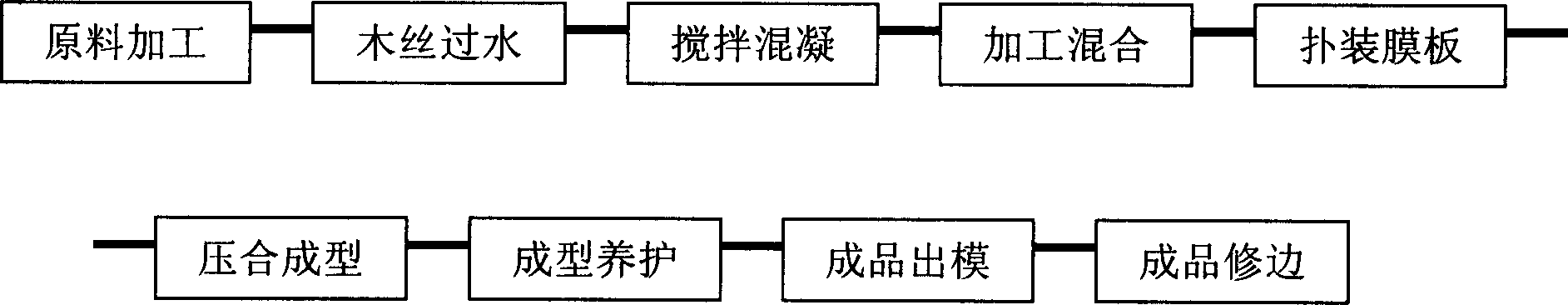

Wooden architecture templet preparation method and the wooden architecture templet prepared by the method

InactiveCN1865186AImprove adhesionEasy decoration constructionCovering/liningsSolid waste managementMaterials processingWood wool

This invention provides a wood architectural mold and the manufacturing method thereof, wherein the raw material components and weight ratio are: wood wool 0.5-1 ton, silicate cement 0.5-4 ton, and water 0.1-1 ton. The procedures comprise: (1)raw material processing, (2)wood wool wetting, (3)concrete mixing, (4)mixing material processing, (5)mold fitting, (6)press molding, (7)molding curing, (8) mould unloading, (9)finished product furnishing. This invention is characterized of fewer amount of wood used and broader application range. It not only can be used as mold connected to the concrete to be used as outside / inside bearing wall of a building, but can be used as inside bearing wall or non bearing wall of a building according to the density of the wood wool. Besides, the surface wood wool has strong adhesive force that enables it easy to be integrated with other decorative building materials, and the surface wood wool line is beautiful and unique which can be used directly as decorative walls.

Owner:富子荣

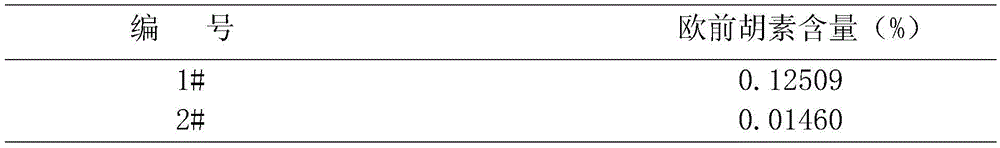

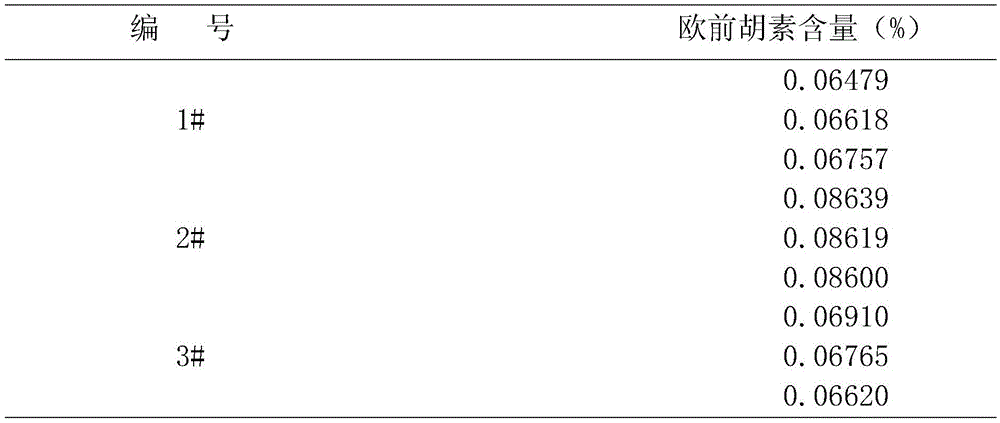

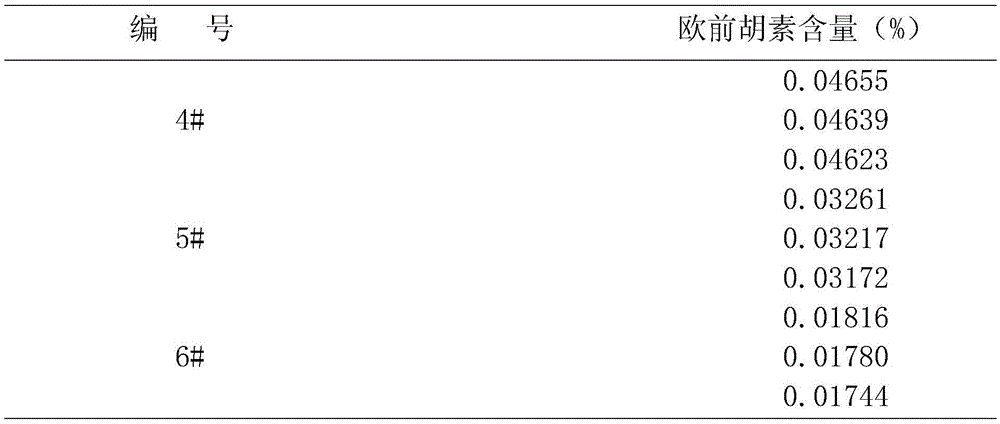

Processing method of root of chuanminshen violaceum

InactiveCN105535049AHigh content of active ingredientsNot easy to mothPlant ingredientsAdditive ingredientChuanminshen violaceum

The invention discloses a processing method of the root of chuanminshen violaceum. The processing method adopts a trapezoidal drying method, and the peeling and smoking of the chuanminshen violaceum are not needed. The trapezoidal drying method comprises the following steps of drying the root of chuanminshen violaceum for 10h at the temperature of 30-40 DEG C, maintaining for 5-10h at the temperature of 55-65 DEG C, controlling the temperature to 75-80 DEG C, and drying. The processing method has the advantages that the content of effective ingredients in the processed root of chuanminshen violaceum is higher, and the easiness in worm damage and mildewing is avoided; the operation is simple, and the popularizing is easy.

Owner:CHENGDU UNIV

Printed composite mat

The invention discloses a printed composite mat, wherein the surface of the mat is printed, the color fastness is good, the cool degree is adjustable, the air permeability is good, the comfort is good, and the mat is safe and wholesome, can be used for a long time and convenient to fold and store. The mat comprises the mat surface and a liner layer, wherein the mat surface is formed by weaving warps and wefts, the warps and the wefts are in a flat belt shape, the component of the warps is regenerated fiber, the component of the wefts is any of or a combination of two or three of polyester fiber, jute fiber and bamboo fiber, and the mat surface is printed. The mat is suitable for being used by people at various ages in four seasons, and can meet double requirements of people for use quality and appearance of a summer sleeping mat.

Owner:台州市丝丝美席业股份有限公司

Compressed Chinese medicine decoction pieces and preparation method thereof

InactiveCN106852940AReduce volumeEasy to adjustPharmaceutical product form changePlant ingredientsPharmacologyRaw material

The present invention proposes a compressed Chinese herbal decoction piece and its preparation method. The compressed Chinese herbal decoction piece is made of traditional Chinese medicine decoction piece or crude drug. The shape itself, the properties of the Chinese herbal decoction pieces or the crude drug in the compressed Chinese herbal decoction pieces remain unchanged. The compressed Chinese medicine decoction pieces of the present invention are small in size, which is beneficial for storage, packaging, storage and transportation; the compressed decoction pieces increase the stability of the Chinese medicine components and reduce the divergence of volatile components; The compressed decoction pieces are convenient for formula adjustment of traditional Chinese medicine, which makes the formula adjustment more accurate and the adjustment efficiency higher; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:韩丰河

Insect-proof and moisture-proof wooden veneer

InactiveCN108943309ACool and strong smellIncrease elasticityCovering/liningsWood working apparatusWood shavingsGlass fiber

The invention discloses an insect-proof and moisture-proof wooden veneer. The wooden veneer comprises the following components of, by weight, 35-55 parts of pine bark, 15-25 parts of beech shavings, 1-3 parts of camphorwood powder, 4-8 parts of mica powder, 0.5-1.5 parts of nano aluminum oxide powder, 0.8-2.2 parts of glass fiber, 4-10 parts of flame retardants, 6-12 parts of adhesives and 5-8 parts of drying agents. The wooden veneer has the advantages of being good in insect-proof performance, not prone to worm damage, good in moisture-proof performance and not prone to mildewing.

Owner:湖州韵高木业有限公司

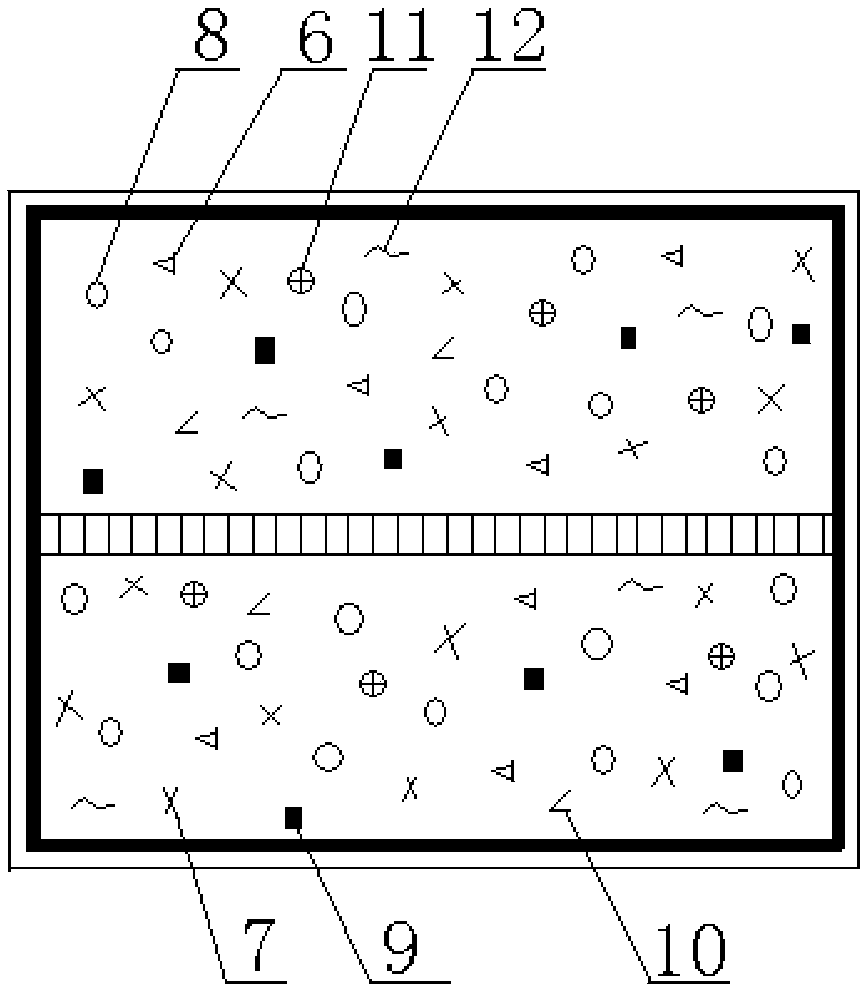

Highly-impact-resistant composite board and preparation method thereof

InactiveCN108312663AReasonable designSimple structureSynthetic resin layered productsLaminationGlass fiberMoisture

The invention relates to a highly-impact-resistant composite board and a preparation method thereof and belongs to the technical field of composite materials and resource regeneration. The highly-impact-resistant composite board is formed by die pressing of a plastic outer-structure layer, glass-fiber cloth, an upper plastic-wood composite material layer, a lower plastic-wood composite material layer and a steel-wire mesh, wherein the steel-wire mesh is positioned between the upper plastic-wood composite material layer and the lower plastic-wood composite material layer; the glass-fiber clothwraps the whole peripheries of the upper plastic-wood composite material layer, the lower plastic-wood composite material layer and the steel-wire mesh; the periphery of the glass-fiber cloth is die-pressed by the plastic outer-structure layer; the plastic outer-structure layer is formed by plastic outer-structure layer boards; the upper plastic-wood composite material layer and the lower plastic-wood composite material layer are respectively formed by plastic-wood composite layer boards. The highly-impact-resistant composite board is simple in structure, convenient in production and manufacture, low in production cost, good in water resistance, difficult in moisture-absorbing expansion, cracking and insect damage, good in impact resistance, more friendly to environment, higher in modulus,larger in rigidity and better in creep resistance.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

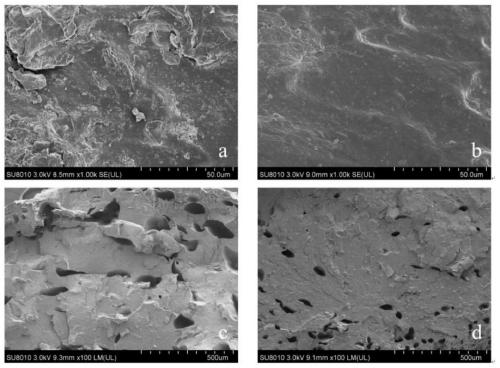

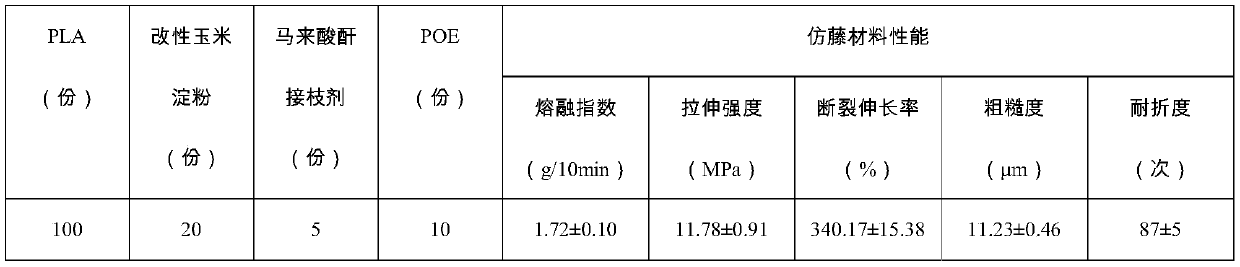

Starch-containing biomass cane-like material and preparation method thereof

The invention discloses a starch-containing biomass cane-like material. The starch-containing biomass cane-like material is prepared from modified starch and thermoplastic plastic; the modified starchis prepared through a following method comprising the steps that raw starch and a modification agent which accounts for 2-20% of the weight of starch are added into a high-speed mixing machine, a mixture is heated to 80-125 DEG C and is stirred for 10-15 min at high speed, and then the modified starch is obtained; a silane coupling agent is adopted as the modification agent, glycerin, hydrochloric acid, sulfuric acid or a hydroxypropyl cellulose solution; the weight ratio of the added modified starch to the added thermoplastic plastic is (20-60):100; one of polylactic acid, low-density polyethylene and linear low-density polyethylene, or a mixture of two or more of polylactic acid, low-density polyethylene and linear low-density polyethylene is adopted as the thermoplastic plastic. The prepared starch-containing biomass cane-like material has good performance, a preparation technology is simple, and the production cost is low.

Owner:NANJING BIOFUNCTION CO LTD

Macadimia nut cultivation insect pest green prevention and control method

The invention discloses a macadimia nut cultivation insect pest green prevention and control method. The method comprises the following steps: whitewashing trunks of macadimia nut trees with a specially-made whitewashing agent to prevent longicorn insect pests and termite insect pests, wherein the trunk and the root of the macadimia nut trees can be effectively prevented from being damaged by thelongicorn insect pests and the termite insect pests without chemical pesticide, and the dosage of chemical pesticide is greatly reduced; thinning out macadimia nut branches, wherein air convection canbe increased, the light transmittance is better, insect pests can be effectively reduced, and meanwhile spreading of various diseases can be effectively controlled; installing solar insecticidal lamps for insect killing, wherein physical insect killing can be achieved, the use amount of chemical pesticide is greatly reduced, and environmental protection is achieved; and spraying lime to the ground of the macadimia nut tree planting land from May to August to kill insects and bacteria, wherein the insect killing and bacterium removing effects are remarkable, the use amount of chemical pesticide can be greatly reduced, and the production cost is reduced.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Manufacturing method of bamboo wall curtain

InactiveCN109483672ANot easy to mothImprove antibacterial propertiesWood compressionWood treatment detailsWaxWater baths

The invention discloses a manufacturing method of a bamboo wall curtain. The manufacturing method of the bamboo wall curtain comprises the steps that step 1, moso bamboo growing over five years is gotten, and then the moso bamboo is processed into bamboo chips, and the thickness of each of the bamboo chips is 2-6mm; step 2, the obtained bamboo chips are put on a machine tool and are subjected to roll-in repeatedly until bamboo oil is squeezed out on the surfaces of the bamboo chips, and then the roll-in process can be stopped; and step 3, the processed bamboo chips are put into an acid solution of acetic anhydride, the PH value of the solution is 3-4, the solution is subjected to water-bath heating for 0.5-1 hour, the heating temperature is 60-70 DEG C, and the bamboo chips are taken out,cleaned and dried after the reaction, and then wood wax oil with lysozyme added is brushed on the surfaces of the bamboo chips and the bamboo chips are dried, and the dried bamboo chips after being arranged and woven are attached to lining paper or lining cloth to form the bamboo curtain. According to the manufacturing method of the bamboo wall curtain, the surfaces of the bamboo chips are provided with the lysozyme, and the mold resistance of the surfaces of bamboo bricks is effectively improved.

Owner:湖北楚风竹韵科技有限公司

Environment-friendly wood-plastic composite floorboard

The invention relates to an environment-friendly wood-plastic composite floorboard which is prepared from the following raw materials in parts by weight: 22-36 parts of regenerated PP, 12-18 parts of microlite, 1.2-2 parts of lubricant, 2-3 parts of antioxidant, 6-9 parts of isooctyl tin dimethyldithioglycolate, 4-8 parts of paraffin, 30-40 parts of polyvinyl chloride resin, 7-12 parts of paraffin, 35-56 parts of waste plant fiber, 0.4-0.7 part of acrylate copolymer 2-3.6 parts of acrylate foaming regulator, 0.3-0.6 part of modifier, 4-12 parts of heat-conducting filler, 3-7 parts of color paste and 4-6 parts of barium stearate. The environment-friendly wood-plastic composite floorboard has the advantages of favorable ultraviolet stability, favorable stainability, high environment friendliness and no pollution, can not be easily eaten by worms, and can be recycled.

Owner:青岛特澳能源检测有限公司

Manufacturing method of bamboo-root carved product not prone to deformation

InactiveCN106363753AAvoid deformationNot easy to mothOrnamental structuresWood treatment detailsSludgeChisel

The invention discloses a manufacturing method of a bamboo-root carved product not prone to deformation. The manufacturing method comprises the following steps that (1) material selection is conducted, specifically, a bamboo root which is not dry and proper in shape is selected; (2) roasting is conducted, specifically, water is added into yellow mud so that the yellow mud can be blended into sludge, the surface of the bamboo root is coated with the sludge 3-5 cm thick, and the bamboo root coated with the sludge is roasted for 2-3 hours in the environment at the temperature of 80-90 DEG C; (3) shaping is conducted, specifically, the sludge on the surface of the roasted bamboo root is removed firstly, the bamboo root is cleaned, the root hair is trimmed, the contour is formed through a chisel, and finally the root carved product is obtained through carving; and (4) polishing, burnishing and painting are conducted to complete root carved product manufacturing, specifically, in the polishing process, the root carved product is polished integrally through raw emery paper, and then polishing is conducted through fine emery paper. The bamboo root carved product manufactured through the manufacturing method is stable in shape and not prone to being damaged by worms or rotted.

Owner:赤水智博艺术雕刻工艺有限责任公司

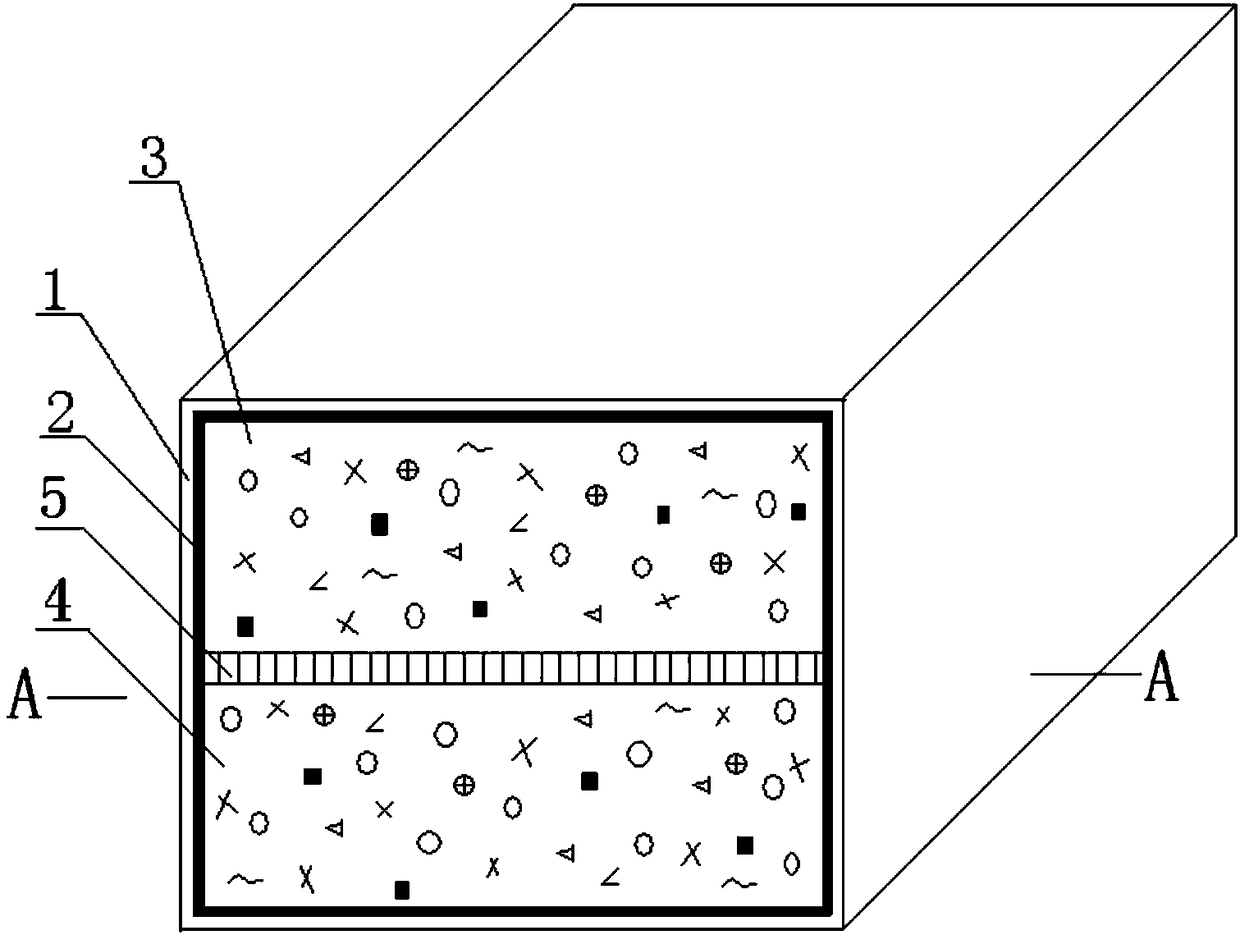

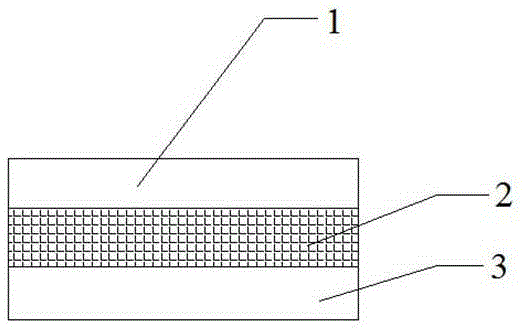

Moth-proof and water-proof solid wood door sheet

InactiveCN105401851ANot easy to mothAvoid deformationConstructions elementsCoatingsSolid woodEngineering

The invention discloses a moth-proof and water-proof solid wood door sheet, which comprises a water-proof layer (1), a solid wood layer (2) and a moth-proof layer (3). The bottom of the water-proof layer (1) is provided with the solid wood layer (2). The bottom of the solid wood layer (2) is provided with the moth-proof layer (3). The water-proof layer (1), the solid wood layer (2) and the moth-proof layer (3) are integrally molded and are bonded together by means of a binding agent. The thickness of the solid wood layer (2) is 200 -400 times the thickness of the water-proof layer (1). The thickness of the solid wood layer (2) is 150-200 times the thickness of the moth-proof layer (3). According to the invention, the moth-proof and water-proof solid wood door sheet is moth-proof, long in service life, good in water-proof effect, not easy to deform, warping-free and cracking-free.

Owner:CHANGSHU LIER BUILDING MATERIAL CO LTD

Kneepad fabric

InactiveCN105077756ANovel shape and styleStylish shapeProtective garmentSpecial outerwear garmentsFiberEngineering

The invention relates to a kneepad fabric comprising a terylene fabric and a flocking snow yarn fabric. The terylene fabric works as a liner; the flocking snow yarn fabric works as an external layer; and the terylene fabric and the flocking snow yarn fabric are sewed together. The kneepad fabric is characterized in that the external surface of the terylene fabric is covered with a bamboo fiber fabric; and warp yarns and weft yarns are interweaved and blended to form the bamboo fiber fabric. The kneepad fabric has a novel and fashionable shape and pattern, bright color to avoid monotony and can be cooperated with high-grade clothes; the kneepad fabric can be easily cleaned, meets demands of modern young ladies; lace can be unnecessary, so men can wear the kneepad; and the kneepad fabric is simply manufactured and is advantaged by great quality, stiffness, wrinkle resistance, strong strength, wear resistance, great moisture resisting property, easy-washing and quick-drying, worm damage prevention and mildew and rot prevention as well as easy storage.

Owner:JIANGSU JUWEI NEW MATERIALS

Preparing method of gastrodia-tuber decoction pieces

The invention discloses a preparing method of gastrodia-tuber decoction pieces. The preparing method mainly includes the steps of cleaning, fumigating, slicing, freezing, drying and the like. According to the gastrodia-tuber decoction pieces prepared with the method, sulfur is not adopted for fumigation in the whole processing process, slow fire processing is also avoided, the defect that sulfur is adopted for fumigation in the prior art is overcome, freezing and drying technologies are adopted, the effects of sufficient drying, mold preventing and quality guaranteeing are achieved, and it isguaranteed that effective ingredients of gastrodia tubers do not run off to the maximum degree; meanwhile, the gastrodia tubers are fumigated through self-made rhizoma chuanxiong liquid, and the medical effects of extinguishing wind to arrest convulsion, repressing liver yang, dispelling wind, removing obstruction in the meridians, treating dizziness, the intermittent headache, the headache, limbnumbness and the like of the gastrodia tubers are further improved.

Owner:贵州润瑞菌业有限责任公司

Environment-friendly low-cost bamboo mat manufacturing method

InactiveCN108638252AEfficient removalImprove thermal stabilityReed/straw treatmentPressure impregnationMicrocrystalline waxUltrasonic dispersion

The invention discloses an environment-friendly low-cost bamboo mat manufacturing method. The manufacturing method comprises the following steps that S1, coconut oleic acid monoethanolamide and waterare added into a preprocessed bamboo bundle for stirring, a silver nitrate solution is dropwise added, stirring is carried out after dropwise adding, the pH value of a system is adjusted to be 8.5-9.2by using a sodium hydroxide, a citric acid solution, microcrystalline wax and hydrogenated castor oil are added so as to carry out closed heating, under the condition that air is introduced, potassium permanganate is added for stirring, the mixture is cooled to the room temperature, and filtering and washing are carried out to obtain a bamboo bundle compound; S2, water and nano montmorillonite are added into the bamboo bundle compound for stirring, and ultrasonic dispersion, filtering and washing are carried out; and S3, the bamboo bundle is fed into a drying and disinfecting carbon drying machine, the heating temperature of the drying and disinfecting carbon drying machine is 160-190 DEG C, the heating time is 2-4 hours, carbonatization is carried out on bamboo powder, the carbonizationdegree is 5%-30%, and then the environment-friendly low-cost bamboo mat is obtained through weaving.

Owner:施文杰

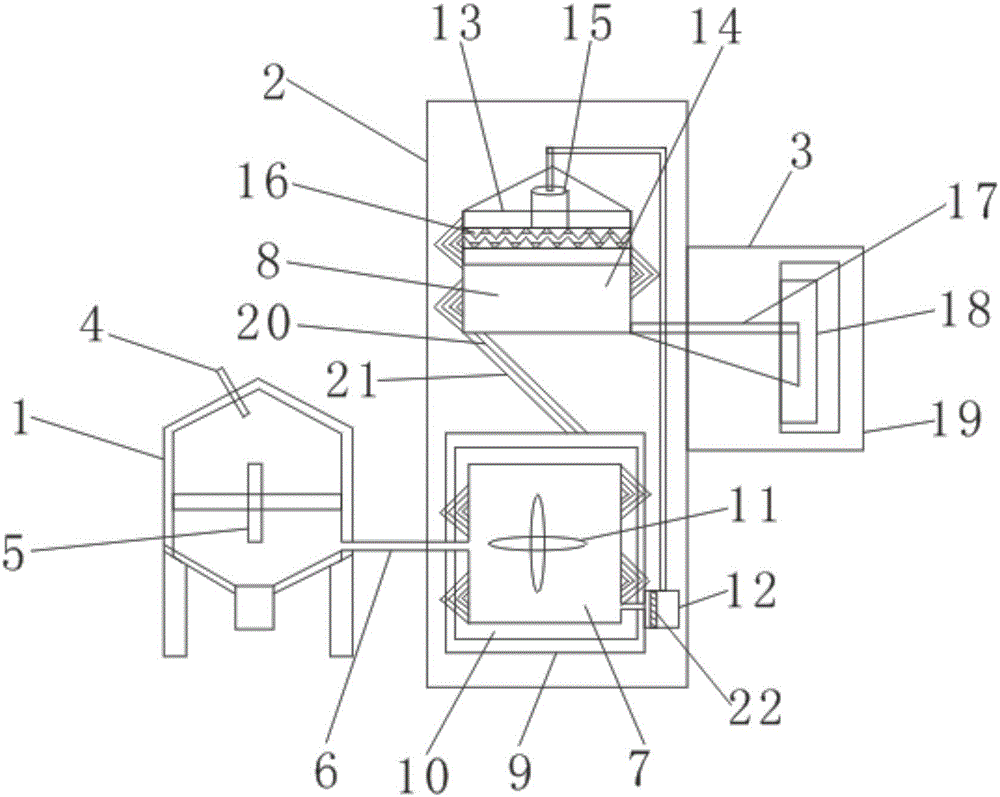

Hunan embroidery thread and production equipment thereof

The invention discloses a Hunan embroidery thread and production equipment thereof. The Hunan embroidery thread is produced from the following raw materials in parts by weight: 50-60 parts of cotton, 20-25 parts of real silks, 10-20 parts of silk floss, 10-20 parts of tencel, 10-15 parts of polyester, 15-20 parts of down feather, 8-12 parts of wool, 3-5 parts of viscose, 1-2 parts of a foaming agent, 1-3 parts of a foaming accelerator, 2-3 parts of reinforced fibers, 8-10 parts of industrial alcohol, 10-15 parts of soda ash, 1-2 parts of table vinegar and 8-13 parts of a plasticizer. Smashing, slurrying and spinning are carried out, so that the embroidery thread is obtained. The Hunan embroidery thread disclosed by the invention has the advantages that the traditional raw materials are adopted mainly, plant raw materials are adopted mainly, treatment is carried out by virtue of some chemical agents, and cooking, slurrying and hot grinding are carried out, so that a large amount of impurity-free slurry can be obtained; and then spinning is carried out, so that protein fibers of the embroidery thread can not be damaged, and protective effect on the embroidery thread is realized.

Owner:CHANGSHA QINGZHUHU EMBROIDERY

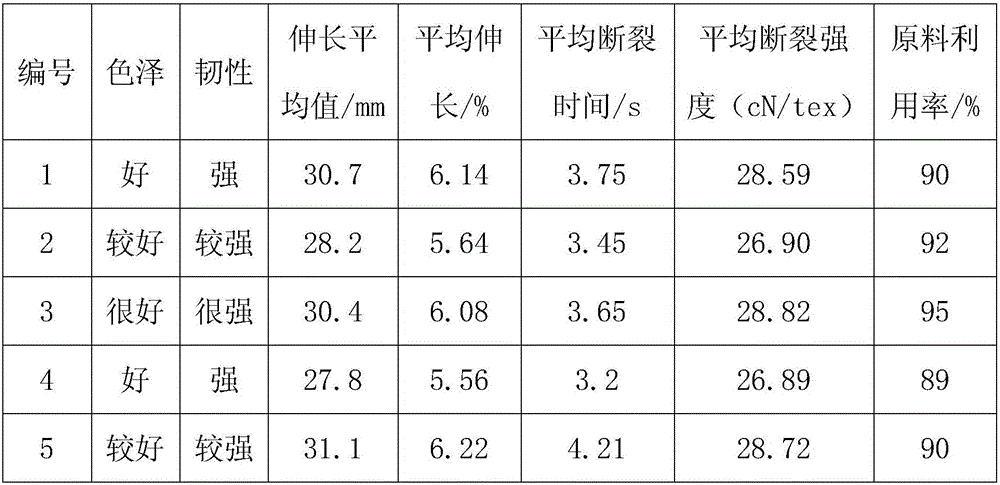

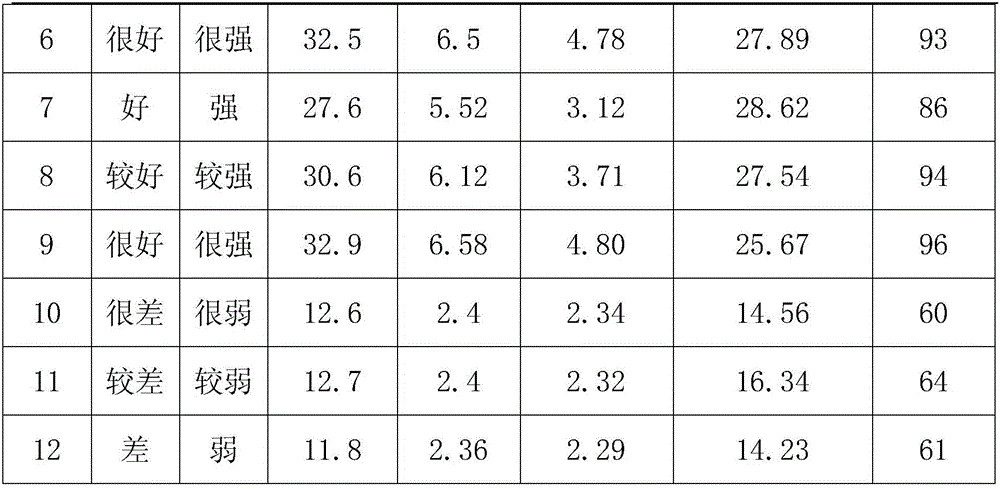

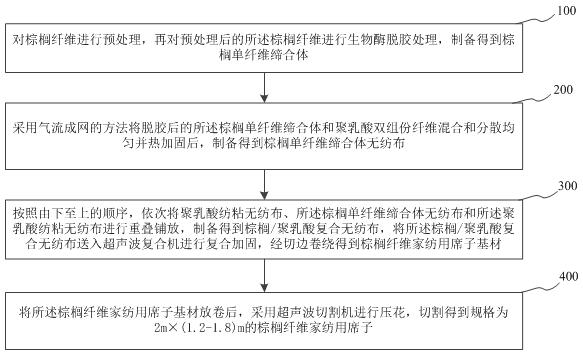

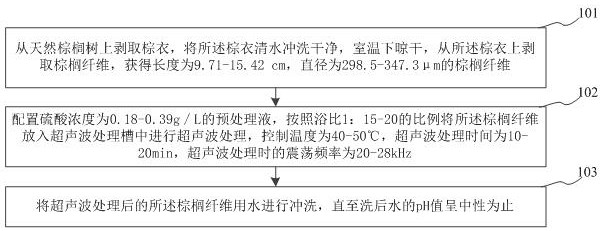

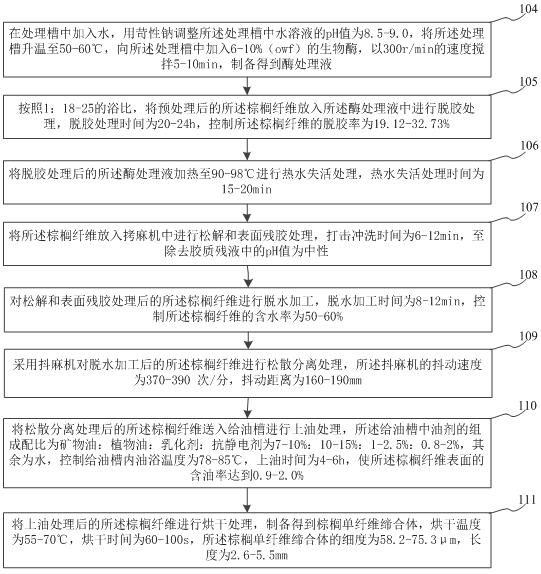

A kind of palm fiber home textile mat and preparation method thereof

ActiveCN110509630BShorten the lengthGood moisture conductivityLamination ancillary operationsBlanketPolymer scienceSingle fibre

The invention discloses a palm fiber home textile mat and a preparation method thereof, and relates to the technical field of home textile materials. The present invention provides a palm fiber home textile mat and a preparation method thereof. The natural palm fiber is partially degummed by a composite method combining ultrasonic pretreatment and biological enzymes to obtain a palm single fiber in which multiple palm single fibers are glued together. The association, and then adopt the air-laid method to control the weight of the air-carrying palm fiber and the polylactic acid bicomponent fiber to make a palm monofilament nonwoven fabric containing the polylactic acid bicomponent fiber, and then pass through the upper layer and the polylactic acid bicomponent fiber. The lower polylactic acid spun-bonded non-woven fabric is compounded to make a palm fiber home textile mat base material, and then cut and welded by an ultrasonic cutting machine to make a semi-durable palm fiber home textile mat. The palm fiber home textile mat utilizes the high hollowness of the palm single fiber and the excellent capillary effect formed by internal folds to achieve good moisture absorption, moisture conduction and air permeability.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com