Preparation method of degradable anti-pollution wood plastic material and product

A wood-plastic material and wood powder technology, which is applied in the field of preparation of degradable and anti-fouling wood-plastic materials, can solve the problems of difficulty in meeting demand, large bearing capacity, shortened furniture life, etc., and achieves long service life, high bearing capacity, Good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of the degradable antifouling wood-plastic material provided in this embodiment comprises the following steps:

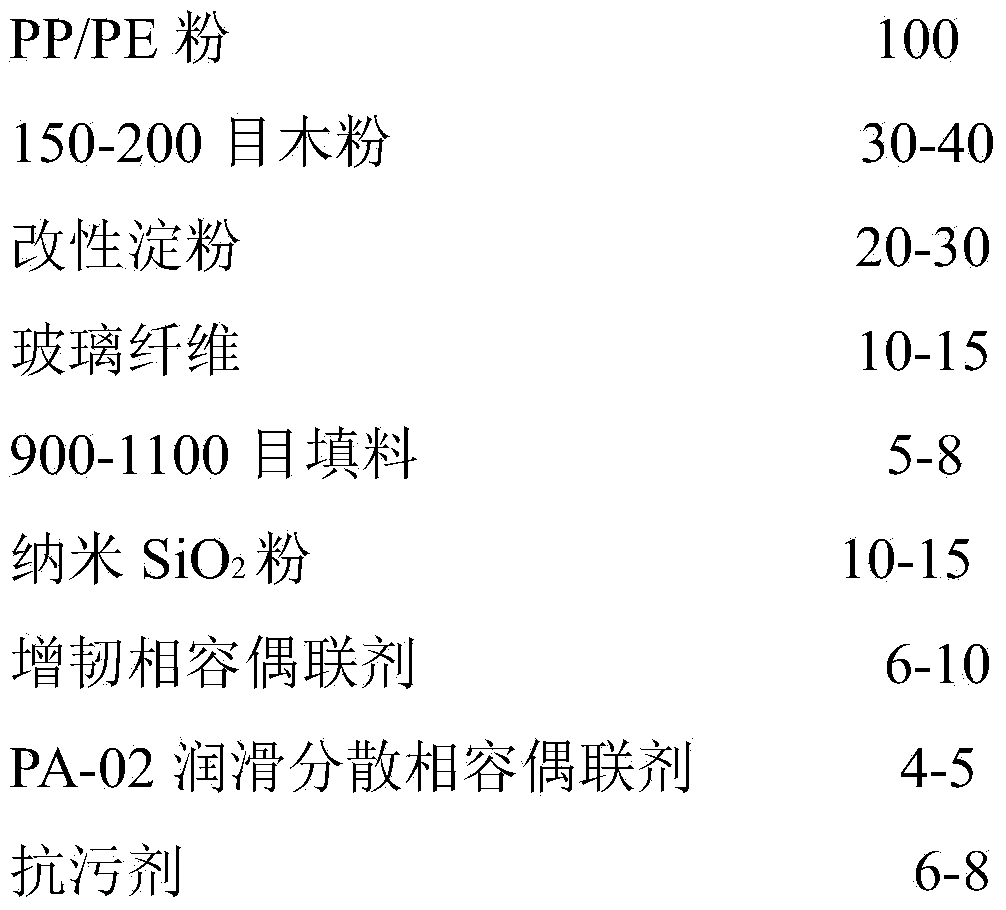

[0017] 1) prepare the following components in weight ratio:

[0018]

[0019]

[0020] Wherein, the wood powder is more than one of wood powder, straw powder, and seed shell powder, and its moisture content is controlled within 1%. The filler is more than one of calcium carbonate, talcum powder, wollastonite and kaolin, and its water content is controlled within 1%. The coupling agent is maleic anhydride grafted polyethylene or maleic anhydride grafted polypropylene. The antifouling agent is fluorosiloxane, poly(heptadecafluorodecyl)methylsiloxane, poly(nonafluorohexyl)siloxane, polymethyl(trifluoropropyl)siloxane, PDMS, One of PTFE. The PA-02 lubricating dispersion compatible coupling agent is compounded with amide compound and maleic anhydride grafted wax according to the corresponding ratio; specifically, in the PA-02 lubric...

Embodiment 2

[0026] The preparation method and product of the degradable antifouling wood-plastic material provided in this example are basically the same as in Example 1, except that it includes the following steps:

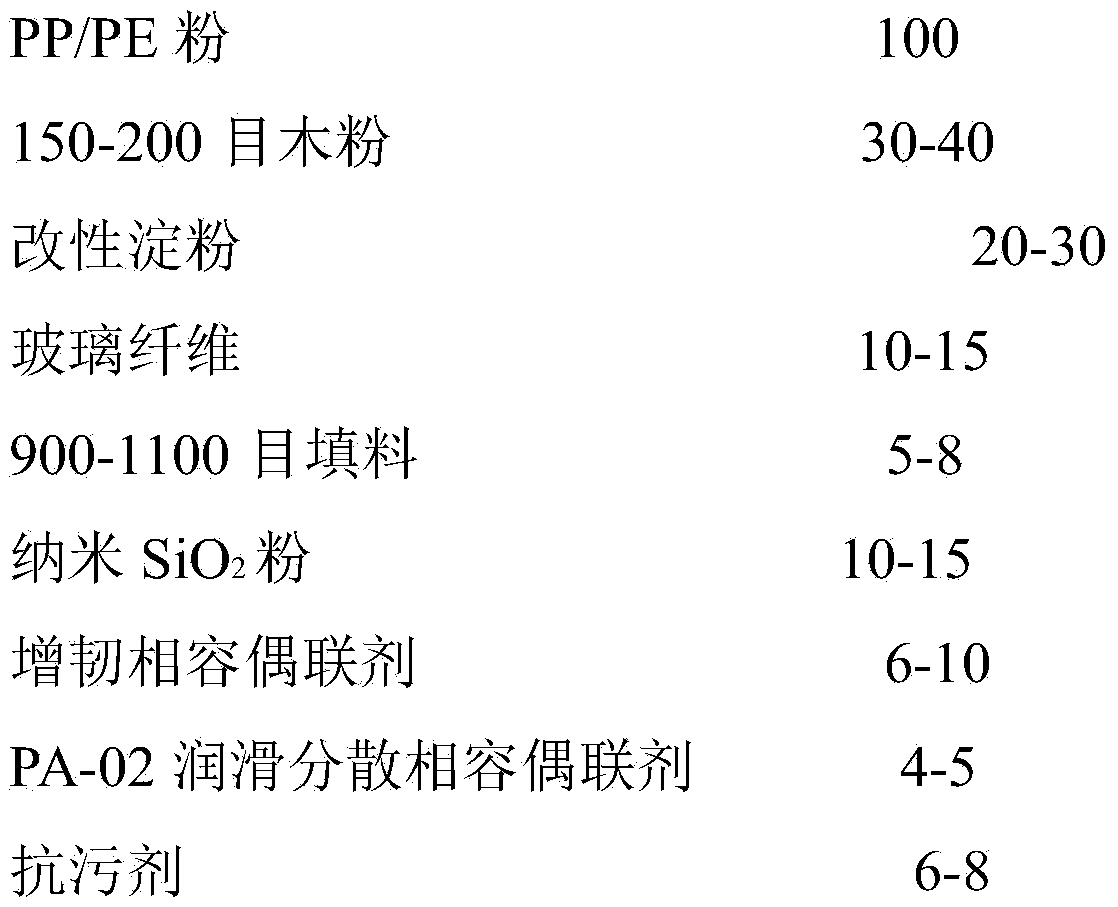

[0027] 1) prepare the following components in weight ratio:

[0028]

[0029] Wherein, the wood powder is wood powder (or bamboo powder), and its water content is controlled within 1%. The filler is talcum powder, and its water content is controlled within 1%. The coupling agent is maleic anhydride grafted polyethylene. The antifouling agent is fluorosilicone. The PA-02 lubricating dispersion compatible coupling agent is compounded with amide compound and maleic anhydride grafted wax according to the corresponding ratio; specifically, in the PA-02 lubricating dispersion compatible coupling agent, The weight ratio of amide complex, maleic anhydride grafted wax, and stearate is 50:30:4. It should be noted that PA-02 lubricating dispersion compatible coupling agent is a p...

Embodiment 3

[0035] The preparation method and product of the degradable antifouling wood-plastic material provided in this example are basically the same as those in Examples 1 and 2, except that it includes the following steps:

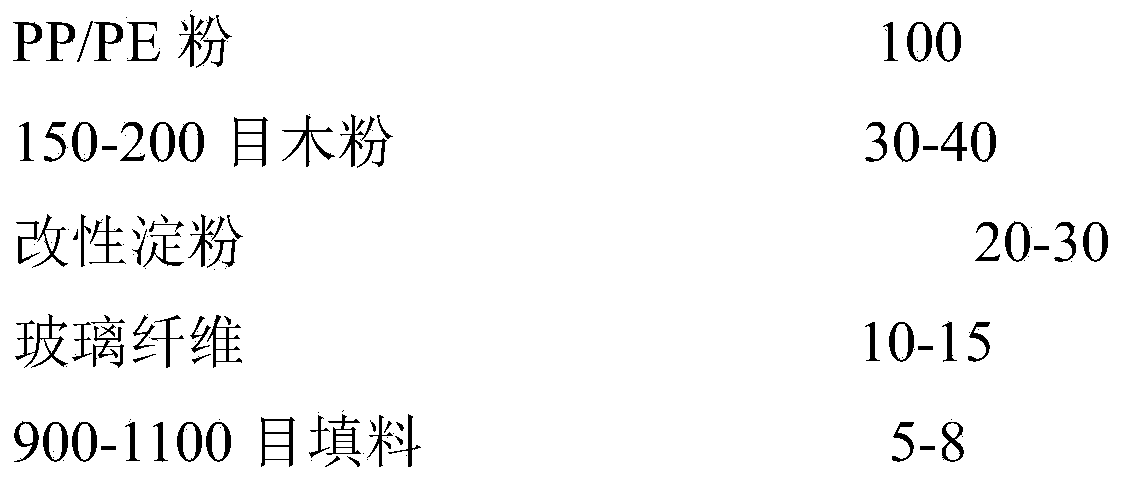

[0036] 1) prepare the following components in weight ratio:

[0037]

[0038] Wherein, the wood powder is straw powder, and its water content is controlled within 1%. The filler is calcium carbonate, and its water content is controlled within 1%. The coupling agent is maleic anhydride grafted polypropylene. The antifouling agent is polyheptadecafluorodecylmethylsiloxane. The PA-02 lubricating dispersion compatible coupling agent is compounded with amide compound and maleic anhydride grafted wax according to the corresponding ratio; specifically, in the PA-02 lubricating dispersion compatible coupling agent, The weight ratio of amide complex, maleic anhydride grafted wax, and stearate is 50:30:4. It should be noted that PA-02 lubricating dispersion compatib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com