Printed composite mat

A printing and transfer printing technology, applied to fabrics, textiles, textiles and papermaking, etc., can solve the problems of occupying space, the mat is not soft enough, easy to age, etc., and achieve the effect of simple and convenient process, good printing effect and high aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

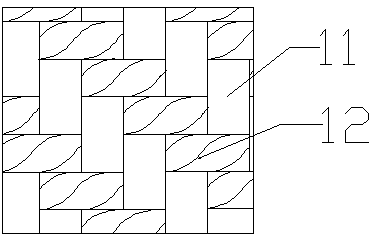

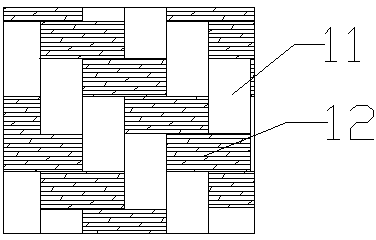

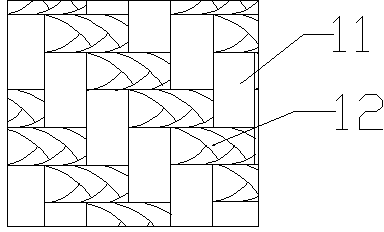

Embodiment 1

[0036] The present embodiment provides a kind of printing composite mat, comprises mat surface and substrate layer, and mat surface is woven by warp thread 11 and weft thread 12, and warp thread 11 and weft thread 12 are all in flat belt shape, and the composition of warp thread 11 is regenerated fiber, weft thread 12 components are polyester fibers, and the mat is provided with printing. The warp thread 11 is a thin sheet made of regenerated fiber and folded into a flat strip shape. The weft thread 12 is made of polyester fiber that accounts for the total component A of the weft thread 12, hemp fiber that accounts for the total component B of the weft thread 12, and the total component of the weft thread 12. Bamboo fibers of C (the ratio of A, B, and C are shown in Table 1) are made into thin wires, and then twist-shaped flat ribbons or braided flat ribbons woven by at least two strands of thin wires or thin wires are intertwined. parallel flat strips, figure 1 It is a schem...

Embodiment 2-13

[0044] In Examples 2-13, other conditions remain the same, as in Example 1, only the ratio of polyester fibers, hemp fibers and bamboo fibers to the total components of the weft 12 is changed, see Table 1 for details.

Embodiment 14

[0046] The present embodiment provides a kind of printing composite mat, comprises mat surface and substrate layer, and mat surface is woven by warp thread 11 and weft thread 12, and warp thread 11 and weft thread 12 are all in flat belt shape, and the composition of warp thread 11 is regenerated fiber, weft thread 12 components are polyester fibers, and the mat is provided with printing. The warp 11 is a thin sheet made of regenerated fiber and folded into a flat strip shape. The weft 12 is made of polyester fiber accounting for 2 / 3 of the total composition of the weft 12 and hemp fiber accounting for 1 / 3 of the total composition of the weft 12. A twisted flat ribbon or a braided flat ribbon or a flat ribbon parallel to each other between thin threads braided by at least two strands of thin threads, the width of the warp 11 and the weft 12 is 0.8mm.

[0047] The printing is processed by the transfer printing process. The transfer printing process is the sublimation transfer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com