Highly-impact-resistant composite board and preparation method thereof

A composite board, high impact resistance technology, applied in the field of composite materials and resource regeneration, can solve the problems of particle board easy expansion, poor mechanical properties, non-degradation, etc., to achieve no waste of forest resources, convenient production and high impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

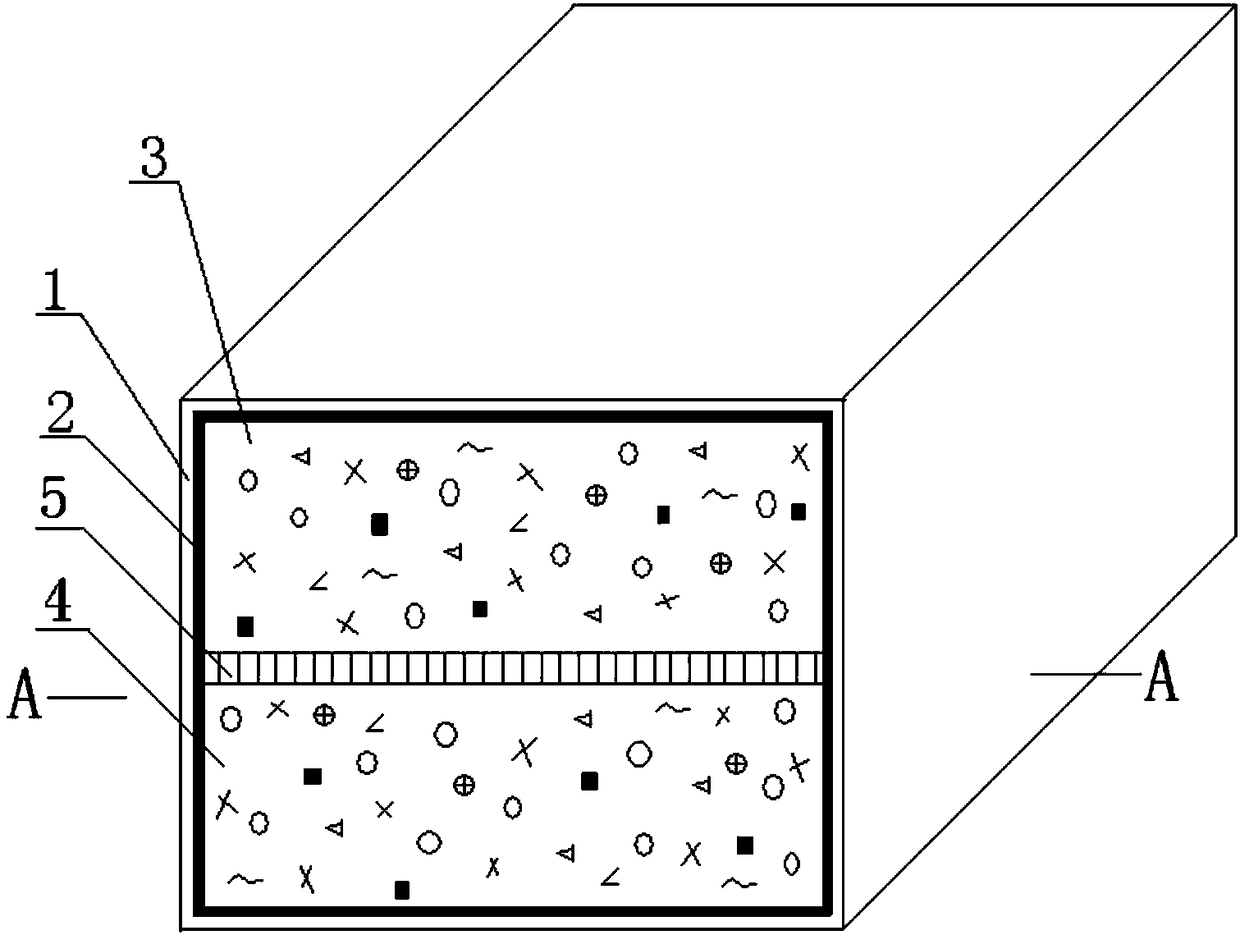

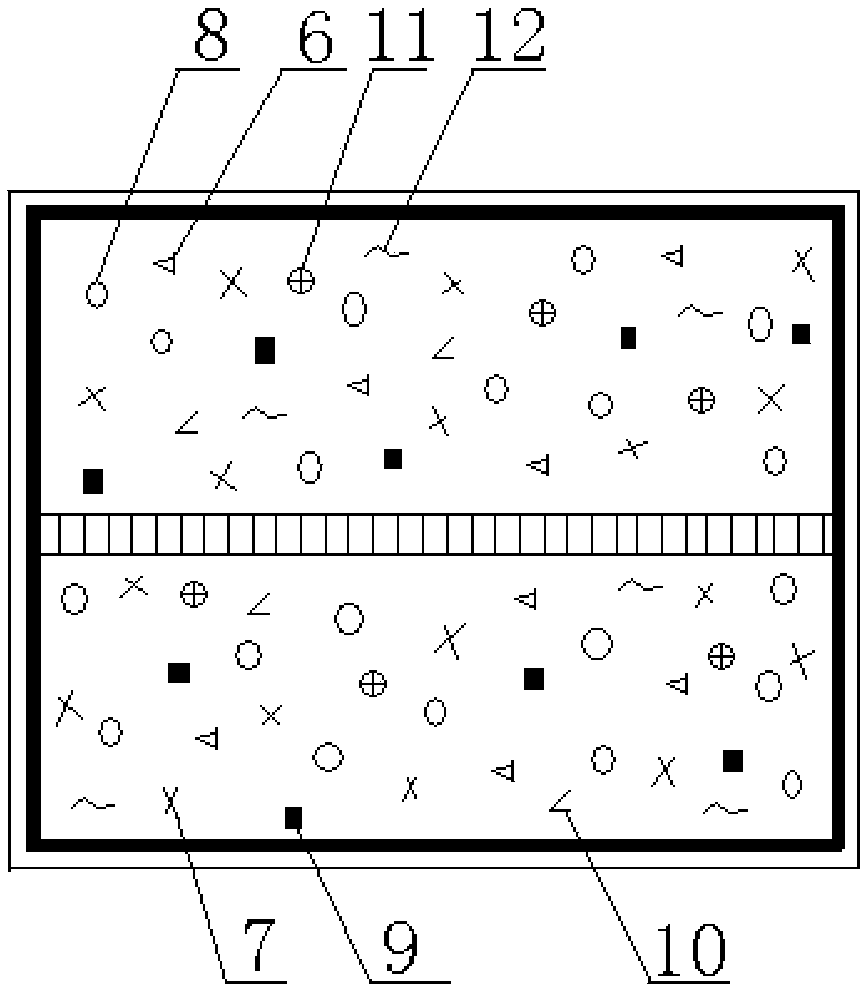

[0040] The present invention also provides a method for preparing a high-impact composite plate, comprising the following steps:

[0041] S1. Combine waste plastics, wood powder, glass beads, rubber powder, silicon nitride whiskers, maleic anhydride, and composite toughening agent in a mass ratio of 100:100-120:4-6:1-5:0.3-0.7 : 10-20: 5-15 Stir and mix evenly, and then calendered into a wood-plastic composite material layer plate for the upper wood-plastic composite material layer and the lower plastic-wood composite material layer, the thickness of the wood-plastic composite material layer plate is 3-5mm;

[0042] S2. Calendering the new plastic material into a plastic outer structural layer plate, the thickness of the plastic outer structural layer plate is 3-5mm;

[0043] S3. Take the mold cavity formed by compression molding, place a layer of plastic outer structural layer plate rolled in step S2 horizontally on the bottom of the mold cavity, and place a layer of plastic...

Embodiment 1

[0050] A method for preparing a high-impact composite plate, the preparation process of which is:

[0051] (1) Mix waste plastics, wood flour (80 mesh), glass beads (true density 0.60g / cm 3 , volume floating rate ≥ 96%), rubber powder (particle size 0.9mm), silicon nitride whisker (fiber diameter 0.35μm, fiber length 30μm), maleic anhydride, composite toughening agent by mass ratio 100:110:5 : 3: 0.5: 15: 10 Stir and mix evenly, and then calender the wood-plastic composite material layer plate for the upper wood-plastic composite material layer and the lower plastic-wood composite material layer. The thickness of the wood-plastic composite material layer plate is 4mm;

[0052] (2) The low-density polyethylene plastic new material is calendered into a plastic outer structural layer sheet, and the thickness of the plastic outer structural layer sheet is 4mm;

[0053] (3) Place a layer of plastic outer structural layer plates horizontally at the bottom of the cavity of the comp...

Embodiment 2

[0058] A method for preparing a high-impact composite plate, the preparation process of which is:

[0059] (1) Mix waste plastics, wood flour (40 mesh), glass beads (true density 0.57g / cm 3 , volume floating rate ≥ 96%), rubber powder (particle size 0.8mm), silicon nitride whisker (fiber diameter 0.1μm, fiber length 10μm), maleic anhydride, composite toughening agent by mass ratio 100:100:4 : 1: 0.3: 10: 5 Stir and mix evenly, and then calendered by a calender to form a wood-plastic composite material layer for the upper wood-plastic composite material layer and the lower plastic-wood composite material layer. The thickness of the wood-plastic composite material layer is 3mm;

[0060] (2) The low-density polyethylene plastic new material is calendered into a plastic outer structural layer sheet, and the thickness of the plastic outer structural layer sheet is 3mm;

[0061] (3) Place a layer of plastic outer structural layer plates horizontally at the bottom of the cavity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com