Hunan embroidery thread and production equipment thereof

A kind of equipment and cotton technology, applied in the field of Hunan embroidery embroidery thread and its production equipment, can solve the problems of complicated production process, pollution of the environment, harmful skin, etc., and achieve the effects of saving energy, improving the utilization rate of heat, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

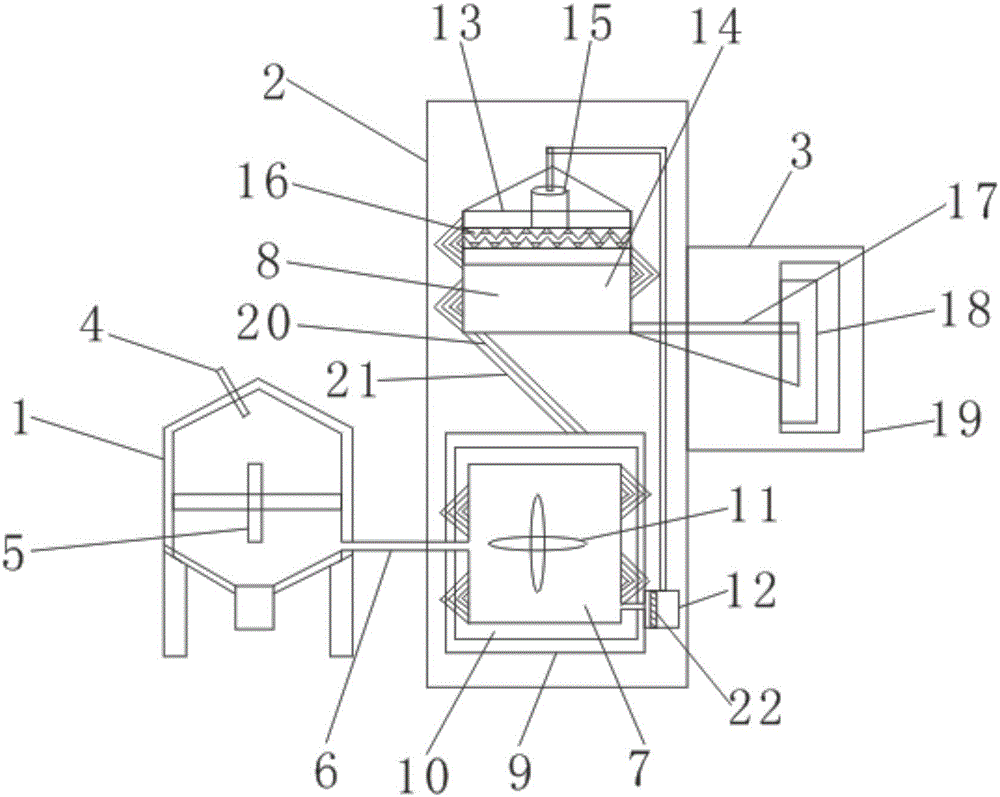

Method used

Image

Examples

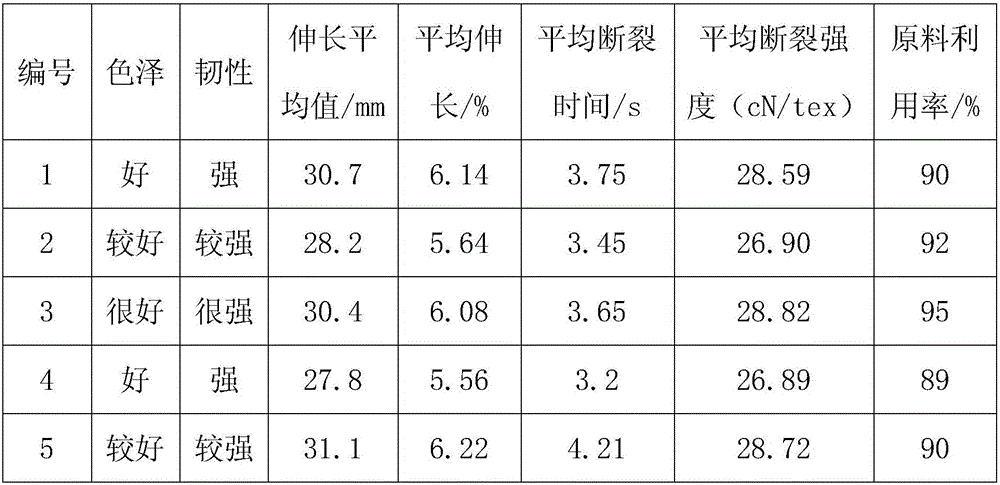

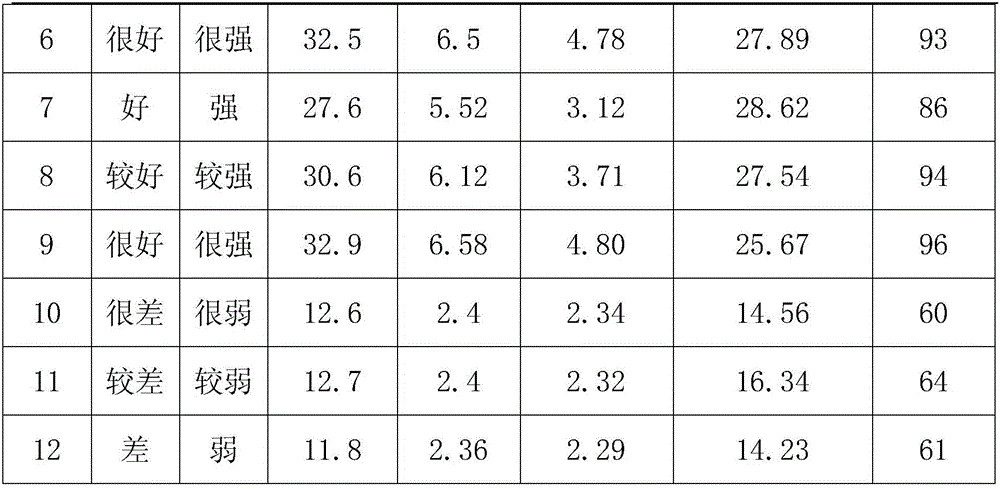

Embodiment 1

[0035] Referring to the examples, the difference from the examples is that the recipe of the Hunan embroidery floss consists of the following raw materials in parts by weight:

[0036] 50 parts of cotton, 20 parts of silk, 10 parts of silk floss, 10 parts of tencel, 10 parts of polyester, 15 parts of down, 8 parts of wool, 3 parts of viscose, 1 part of foaming agent, 1 part of foaming accelerator, 2 parts of reinforcing fiber , 8 parts of industrial alcohol, 10 parts of soda ash, 1 part of vinegar, and 8 parts of plasticizer.

[0037] In the operation step (2), in the process of high-temperature and high-pressure cooking, keep the required temperature at 90°C, the pressure at 10MPa, the cooking time for 8 hours, the viscosity at 0.2mD, and keep the temperature of the upper and lower millstones at 100°C . The protein fiber content in the embroidery floss prepared in this embodiment is about 42.4%.

Embodiment 2

[0039] Referring to Example 1, the difference from Example 1 is that in the operation step (2), during the process of high-temperature and high-pressure cooking, the required temperature is maintained at 100°C, the pressure is 12.5MPa, and the cooking time is 9h. The viscosity is 0.3mD, and the temperature of the upper and lower grinding discs is kept at 110°C. The protein fiber content in the embroidery floss prepared in this embodiment is about 41.1%.

Embodiment 3

[0041] Referring to Example 1, the difference from Example 1 is that in the operation step (2), in the process of high-temperature and high-pressure cooking, the required temperature is maintained at 110°C, the pressure is 15MPa, the cooking time is 10h, and the viscosity 0.4mD, keep the temperature of the upper grinding plate and the lower grinding plate at 120°C. The protein fiber content in the embroidery floss prepared in this embodiment is about 44.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com